Table of Contents

Worm and Worm Wheel: A Comprehensive Guide

Worm and worm wheel are essential components in various mechanical systems, providing a smooth and efficient way to transfer motion and power. These components are commonly used in industries such as automotive, aerospace, and robotics. In this article, we will delve into the intricacies of worm and worm wheel, exploring their functions, applications, and the benefits of using customized CNC Machining Services for their production.

Worm and worm wheel are essential components in various mechanical systems, providing a smooth and efficient way to transfer motion and power. These components are commonly used in industries such as automotive, aerospace, and robotics. In this article, we will delve into the intricacies of worm and worm wheel, exploring their functions, applications, and the benefits of using customized CNC Machining Services for their production.

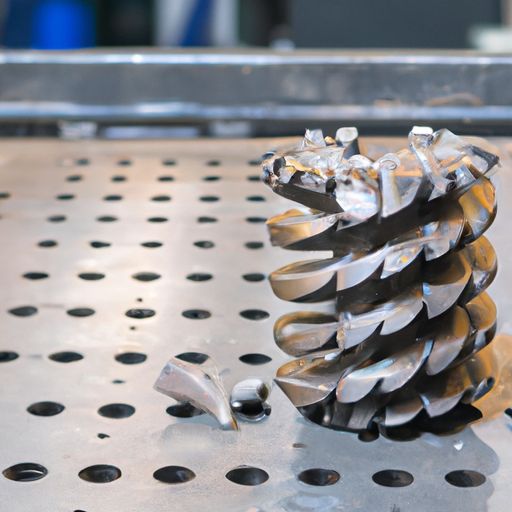

A worm is a type of gear that resembles a screw, with a helical Thread wrapped around a cylindrical shaft. It is typically used to transmit motion between non-intersecting Shafts at right angles. The worm wheel, also known as a worm gear, is a toothed wheel that meshes with the worm to transfer motion and power. The unique design of the worm and worm wheel allows for high gear reduction ratios and smooth, quiet operation.

One of the key advantages of using worm and worm wheel in mechanical systems is their ability to provide high gear reduction ratios. This means that a small input rotation of the worm can result in a large output rotation of the worm wheel, making them ideal for applications where precise control and slow speed are required. Additionally, the meshing of the worm and worm wheel creates a self-locking mechanism, preventing back-driving and ensuring stability in the system.

The applications of worm and worm wheel are diverse, ranging from automotive steering systems to Industrial Machinery and robotics. In automotive applications, worm and worm wheel are commonly used in steering Gearboxes to convert the rotational motion of the steering wheel into the lateral motion of the wheels. In industrial machinery, they are used in conveyor systems, lifting equipment, and other applications that require precise motion control. In robotics, worm and worm wheel are used in robotic arms and other mechanisms that require high gear reduction ratios and precise positioning.

When it comes to manufacturing worm and worm wheel, precision is key. Customized CNC machining services offer a cost-effective and efficient way to produce high-quality worm and worm wheel with tight tolerances and complex geometries. CNC machining allows for the production of custom worm and worm wheel designs tailored to specific requirements, ensuring optimal performance and reliability in the final product.

By utilizing customized CNC machining services for the production of worm and worm wheel, manufacturers can benefit from increased efficiency, reduced Lead times, and improved quality control. CNC machining allows for the production of complex geometries and tight tolerances with high precision, ensuring that each component meets the exact specifications required for the application. Additionally, CNC machining offers flexibility in design iterations and modifications, allowing for quick adjustments to be made to the production process as needed.

In conclusion, worm and worm wheel are essential components in various mechanical systems, providing high gear reduction ratios and precise motion control. Customized CNC machining services offer a cost-effective and efficient way to produce high-quality worm and worm wheel with tight tolerances and complex geometries. By leveraging CNC machining for the production of worm and worm wheel, manufacturers can benefit from increased efficiency, reduced lead times, and improved quality control, ensuring optimal performance and reliability in the final product.