Table of Contents

Benefits of Using a Spot Welder in Welding Applications

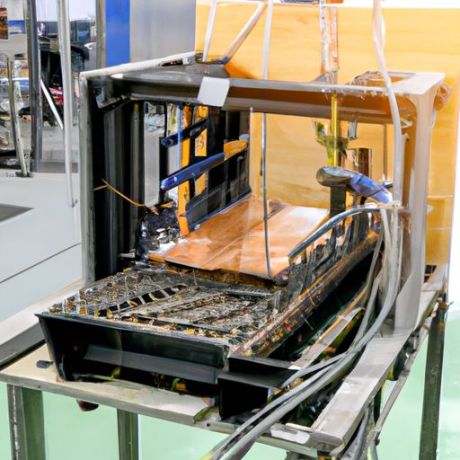

Spot welding is a popular method used in the welding industry for joining two or more metal pieces together. It is a quick and efficient process that produces strong and durable welds. One of the key tools used in spot welding is a spot welder, also known as a resistance spot welder. This machine applies pressure and heat to the metal pieces to create a weld. In this article, we will discuss the benefits of using a spot welder in welding applications.

One of the main advantages of using a spot welder is its speed and efficiency. Spot welding can be completed in a matter of seconds, making it a fast and cost-effective method for joining metal pieces. This is especially useful in high-volume production environments where time is of the essence. Spot Welders are also easy to operate, requiring minimal training for operators to use effectively.

Another benefit of using a spot welder is the strength of the welds it produces. Spot welding creates a strong bond between the metal pieces, making it ideal for applications where durability is essential. The welds created by a spot welder are also consistent and reliable, ensuring a high level of quality in the finished product.

Spot welders are versatile machines that can be used on a wide range of materials, including steel, Aluminum, and Copper. This makes them suitable for a variety of welding applications, from automotive manufacturing to electronics production. Spot welders can also be used to weld different thicknesses of metal, making them a flexible tool for various projects.

In addition to their speed, strength, and versatility, spot welders are also energy-efficient machines. Spot welding requires less energy compared to other welding methods, making it a more environmentally friendly option. This can result in cost savings for businesses in terms of energy consumption and operating costs.

Spot welders are also compact and portable machines, making them easy to transport and set up in different locations. This makes them ideal for on-site welding projects or for businesses with limited space in their facilities. Spot welders are also relatively low maintenance machines, requiring minimal upkeep to keep them running smoothly.

Overall, spot welders offer a range of benefits for welding applications, including speed, efficiency, strength, versatility, energy efficiency, and portability. These machines are a valuable tool for businesses looking to improve their welding processes and produce high-quality welds in a cost-effective manner. Whether you are in the automotive, electronics, or manufacturing industry, a spot welder can help you achieve your welding goals with ease and precision.