Table of Contents

Casing vs. Tubing: Understanding the Key Differences

Casing and tubing are two essential components in the oil and gas industry, used in drilling and completing wells. While they may seem similar at first glance, there are key differences between the two that are important to understand. In this article, we will explore the distinctions between casing and tubing to help you better grasp their roles and functions in the drilling process.

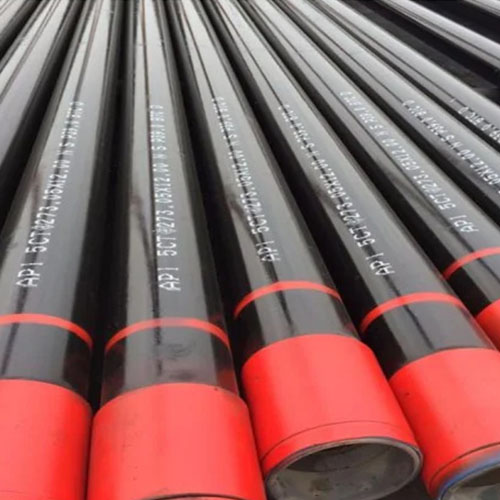

Casing is a large-diameter pipe that is installed in a wellbore to provide structural integrity and support the walls of the well. It is typically made of steel and comes in various sizes and grades to suit different drilling conditions. Casing is run from the surface of the well Down to the desired depth, where it is cemented in place to prevent the collapse of the wellbore and protect the surrounding formations from contamination.

Tubing, on the other hand, is a smaller-diameter pipe that is run inside the casing to facilitate the production of oil and gas from the well. Tubing is also made of steel and comes in different sizes and grades, but it is designed to withstand the pressures and temperatures of production operations. Tubing is typically run from the bottom of the well up to the surface, where it is connected to production equipment such as Pumps and separators.

One of the main differences between casing and tubing is their size and diameter. Casing is larger and thicker than tubing, as it needs to provide structural support and withstand the weight of the surrounding formations. Tubing, on the other hand, is smaller and more flexible, allowing for the flow of fluids from the reservoir to the surface.

Another key difference between casing and tubing is their function in the well. Casing is primarily used to protect the wellbore and prevent it from collapsing, while tubing is used to transport oil and gas from the reservoir to the surface. Casing is also used to isolate different formations and prevent the migration of fluids between them, while tubing is used to control the flow of production fluids and facilitate the installation of downhole equipment.

In terms of installation, casing is typically run first in a wellbore, followed by tubing. This sequential installation allows for the proper support and protection of the wellbore before production operations begin. Casing is cemented in place to create a secure barrier between the wellbore and the surrounding formations, while tubing is connected to the production equipment at the surface to facilitate the flow of fluids.

In conclusion, casing and tubing are essential components in the drilling and completion of oil and gas wells. While they may seem similar in material and construction, there are key differences in their size, function, and installation that make them distinct from each other. Understanding these differences is crucial for ensuring the safe and efficient operation of oil and gas wells.