Table of Contents

Troubleshooting Tips for Siemens S7-300 PLC (6ES79538-LG31-0AA0)

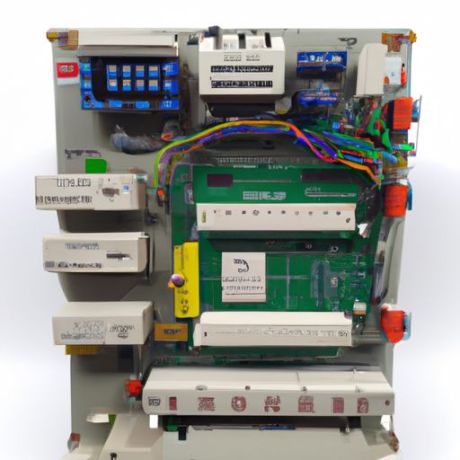

Siemens S7-300 PLCs are widely used in industrial automation due to their reliability and flexibility. However, like any electronic device, they can encounter issues that require troubleshooting. In this article, we will discuss some common problems that users may encounter with the Siemens S7-300 PLC (6ES79538-LG31-0AA0) and provide tips on how to resolve them.

One of the most common issues with the Siemens S7-300 PLC is communication problems. This can be caused by a variety of factors, such as faulty cables, incorrect network settings, or a malfunctioning communication module. To troubleshoot communication issues, start by checking the physical connections and ensuring that the cables are securely plugged in. Next, verify that the network settings are configured correctly in the PLC program. If the issue persists, try replacing the communication module or contacting Siemens technical support for further assistance.

Another common problem with the Siemens S7-300 PLC is programming errors. This can occur due to mistakes in the PLC program, such as incorrect logic or syntax errors. To troubleshoot programming errors, carefully review the PLC program and look for any mistakes or inconsistencies. Use the Diagnostic Tools provided by Siemens Step 7 Software to identify and correct errors in the program. Additionally, consider testing the program in a simulation Environment before downloading it to the PLC to prevent potential issues.

Hardware failures can also occur with the Siemens S7-300 PLC, such as malfunctioning input/output modules or Power Supplies. To troubleshoot hardware failures, start by checking the status LEDs on the modules to identify any issues. If a module is not functioning properly, try replacing it with a known working module to see if the problem is resolved. Additionally, check the power supply unit to ensure that it is providing the correct voltage and current to the PLC. If hardware failures persist, consider contacting Siemens technical support for further assistance.

Intermittent issues with the Siemens S7-300 PLC can be particularly challenging to troubleshoot. These issues may be caused by loose connections, temperature fluctuations, or electromagnetic interference. To troubleshoot intermittent issues, carefully inspect the PLC and its components for any loose connections or damaged cables. Consider relocating the PLC to a more stable environment with consistent temperature and minimal electromagnetic interference. If the problem persists, consider using diagnostic tools to monitor the PLC’s performance and identify any patterns or trends that may help pinpoint the root cause of the issue.

In conclusion, troubleshooting the Siemens S7-300 PLC (6ES79538-LG31-0AA0) requires a systematic approach to identify and resolve issues effectively. By following the tips outlined in this article, users can address common problems with communication, programming, hardware, and intermittent issues. Remember to consult the Siemens S7-300 PLC manual and technical support resources for additional guidance and support. With proper troubleshooting techniques and attention to detail, users can maintain the reliability and performance of their Siemens S7-300 PLC for years to come.

In conclusion, troubleshooting the Siemens S7-300 PLC (6ES79538-LG31-0AA0) requires a systematic approach to identify and resolve issues effectively. By following the tips outlined in this article, users can address common problems with communication, programming, hardware, and intermittent issues. Remember to consult the Siemens S7-300 PLC manual and technical support resources for additional guidance and support. With proper troubleshooting techniques and attention to detail, users can maintain the reliability and performance of their Siemens S7-300 PLC for years to come.