Table of Contents

Rubber Filler: Understanding its Importance in Manufacturing Processes

Rubber filler plays a crucial role in the manufacturing processes of various Rubber Products. From automotive tires to industrial Seals, the addition of fillers enhances the performance and properties of rubber compounds. In China, high-quality rubber filler factories are instrumental in meeting the demands of the global market.

Understanding the significance of rubber fillers requires delving into their functions within rubber compounds. Fillers are materials added to rubber to improve its physical properties, such as strength, durability, and resistance to wear and tear. They also contribute to cost-effectiveness by reducing the amount of expensive rubber needed in formulations.

In China, high-quality rubber filler factories utilize a range of materials, including carbon black, silica, clay, and calcium carbonate. Carbon black, derived from the incomplete combustion of petroleum products, is one of the most widely used fillers due to its excellent reinforcing properties. Silica, on the other hand, offers improved abrasion resistance and helps enhance fuel efficiency in tires.

The manufacturing process of rubber fillers involves precise control over particle size, shape, and surface chemistry. This ensures compatibility with rubber matrices and optimal reinforcement. Chinese factories employ advanced technologies and stringent quality control measures to produce fillers that meet international standards.

One of the key advantages of rubber fillers is their ability to tailor the mechanical properties of rubber compounds. By adjusting filler loading and types, manufacturers can achieve desired characteristics such as hardness, tensile strength, and elasticity. This versatility makes rubber fillers indispensable in a wide range of industries, including automotive, construction, and aerospace.

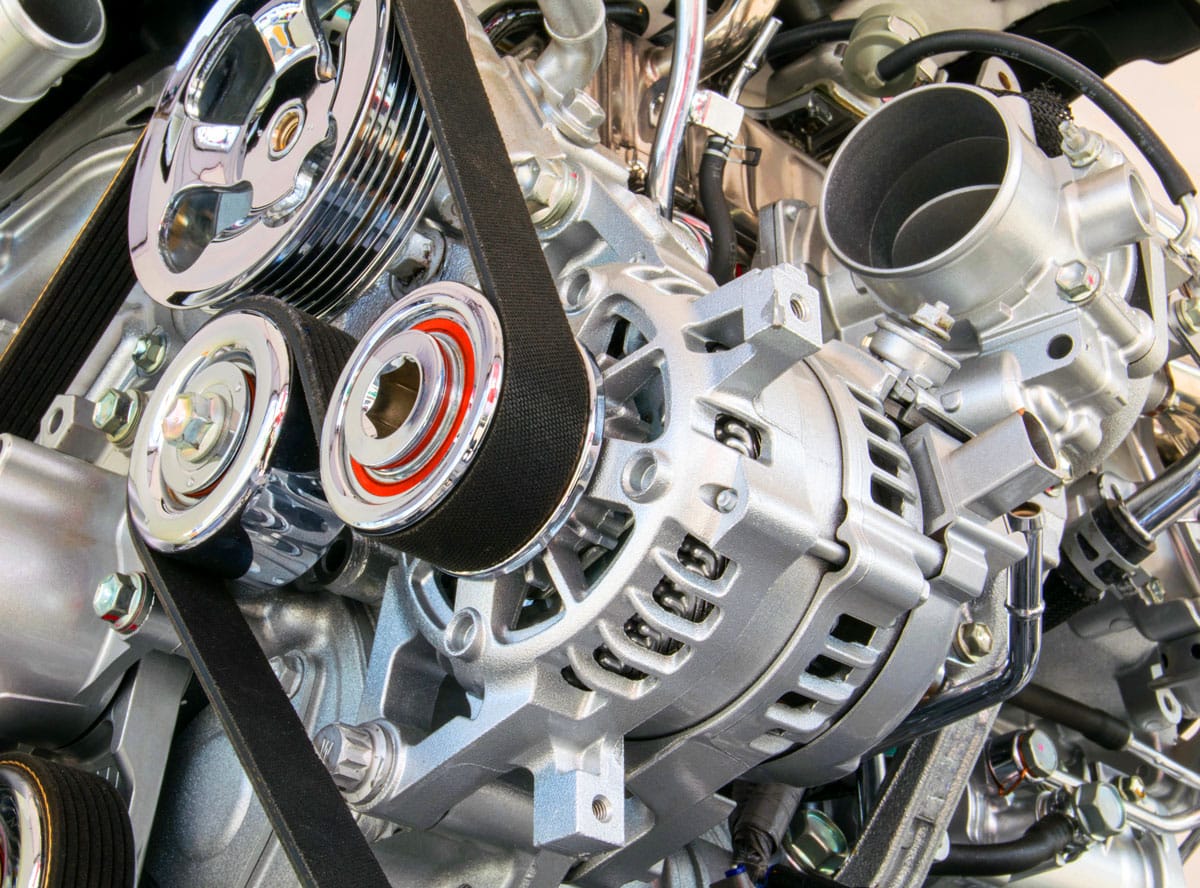

In automotive applications, for instance, rubber fillers contribute to tire performance, fuel efficiency, and Safety. High-quality fillers enable tire manufacturers to produce products that meet stringent regulatory requirements while delivering superior performance on the road. Similarly, in industrial applications, rubber seals and Gaskets reinforced with fillers exhibit enhanced durability and resistance to harsh operating conditions.

China’s prominence in the global rubber filler market stems from its advanced manufacturing capabilities and competitive pricing. High-quality factories leverage economies of scale and efficient production processes to offer cost-effective solutions to customers worldwide. Moreover, China’s strategic location and robust supply chain infrastructure facilitate timely delivery of products to international markets.

The demand for high-quality rubber fillers continues to grow as industries seek to optimize product performance and reduce environmental impact. Sustainable fillers, such as bio-based materials and Recycled Rubber, are gaining traction as manufacturers prioritize eco-friendly alternatives. Chinese factories are at the forefront of innovation in this regard, investing in research and development to create sustainable filler solutions that meet evolving market needs.

In conclusion, rubber fillers play a vital role in enhancing the performance and properties of rubber compounds used in various industries. China’s high-quality filler factories are instrumental in meeting the global demand for cost-effective and sustainable solutions. By leveraging advanced technologies and rigorous quality control measures, these factories contribute to the continued advancement of rubber manufacturing processes worldwide.

Exploring the Top Characteristics of High-Quality Rubber Fillers from China

Rubber fillers play a crucial role in various industries, from automotive to construction, providing essential properties such as reinforcement, resilience, and durability to rubber-based products. Among the many producers of rubber fillers, China stands out as a prominent supplier, known for its high-quality manufacturing processes and products. In this article, we delve into the top characteristics of high-quality rubber fillers from China, highlighting why they are sought after in global markets.

First and foremost, quality control is paramount in the production of rubber fillers in China. Top manufacturers implement stringent quality assurance measures throughout the manufacturing process, from raw material selection to final product testing. This commitment to quality ensures consistency and reliability in the performance of rubber fillers, meeting the stringent requirements of diverse industries.

Furthermore, high-quality rubber fillers from China exhibit excellent compatibility with various rubber matrices. Manufacturers invest in research and development to formulate fillers that seamlessly integrate with different types of rubber compounds, enhancing their mechanical properties without compromising other performance aspects. This compatibility allows for versatility in application, catering to the specific needs of different industries and end-users.

| Brand | Product |

| MoGen | Lubricating oils |

Moreover, high-quality rubber fillers from China boast superior reinforcement capabilities. Through precise engineering and formulation, these fillers effectively enhance the tensile strength, tear resistance, and abrasion resistance of rubber products. Whether used in tires, conveyor belts, or molded rubber parts, these fillers contribute to the overall durability and longevity of the end products, thereby reducing maintenance costs and enhancing operational efficiency.

In addition to reinforcement, high-quality rubber fillers from China offer excellent dispersion properties. Proper dispersion is essential for achieving uniformity and consistency in rubber compounds, ensuring optimal performance and product quality. Leading manufacturers utilize advanced processing techniques and equipment to achieve uniform dispersion of fillers within rubber matrices, resulting in enhanced mechanical properties and a smooth surface finish in finished products.

Another key characteristic of high-quality rubber fillers from China is their environmental friendliness. As sustainability becomes increasingly important in today’s global landscape, manufacturers prioritize the use of eco-friendly materials and production processes. From sourcing renewable raw materials to implementing energy-efficient manufacturing practices, these efforts contribute to reducing the environmental footprint of rubber filler production while meeting regulatory standards and customer expectations.

Furthermore, high-quality rubber fillers from China are backed by comprehensive technical support and customer service. Manufacturers understand the importance of providing timely assistance and expertise to their clients, whether it’s in product selection, formulation optimization, or troubleshooting. By offering reliable technical support, they forge long-term partnerships with customers, fostering mutual trust and satisfaction.

In conclusion, high-quality rubber fillers from China exhibit a combination of characteristics that set them apart in the global market. From stringent quality control and compatibility to superior reinforcement and dispersion properties, these fillers meet the diverse needs of industries reliant on rubber-based products. Moreover, their commitment to environmental sustainability and customer-centric approach further solidify their reputation as top-tier manufacturers. As demand for high-performance rubber fillers continues to grow, China remains a reliable source for quality products and technical expertise.

Behind the Scenes: A Deep Dive into the Production Process of Rubber Fillers in China

Rubber fillers play a crucial role in enhancing the properties of rubber products, contributing to their durability, strength, and resilience. Behind the scenes, in China, numerous factories are dedicated to the production of high-quality rubber fillers, utilizing advanced techniques and technologies to meet the demands of various industries. In this article, we delve into the intricate production process of rubber fillers in China, shedding light on the meticulous steps involved in delivering superior-quality products.

The journey of rubber fillers begins with the selection of raw materials, which are sourced from reputable suppliers known for their consistency and quality. These raw materials typically include various types of carbon black, silica, and other reinforcing agents, each chosen for its specific properties and intended application. Stringent quality control measures are implemented at this stage to ensure that only the finest materials are used in the production process.

Once the raw materials are acquired, they undergo a series of processing steps to achieve the desired characteristics. One such step is the mixing process, where the raw materials are blended together in precise proportions to create a homogeneous mixture. This mixture is then subjected to intense pressure and temperature conditions in a process known as compounding, which facilitates the bonding of the materials and the activation of their reinforcing properties.

Following compounding, the rubber filler mixture undergoes further processing to refine its texture and consistency. This may involve additional mixing, milling, and extrusion processes to ensure uniformity and eliminate any impurities or inconsistencies. Advanced equipment and machinery are employed throughout these processes to maintain strict quality standards and optimize production efficiency.

Once the rubber filler mixture reaches the desired specifications, it is shaped into the final product using specialized molding techniques. Depending on the intended application, the filler may be formed into granules, pellets, or powder forms, each tailored to meet the unique requirements of different industries. Precision molding techniques are employed to achieve the desired size, shape, and density of the filler, ensuring optimal performance in end-use applications.

Throughout the production process, quality control remains a top priority, with rigorous testing and inspection procedures implemented at every stage. Samples of the rubber filler are regularly analyzed for physical, chemical, and mechanical properties to verify compliance with industry standards and customer specifications. Any deviations or anomalies are promptly addressed to maintain consistency and quality across batches.

Once the production process is complete, the finished rubber fillers are carefully packaged and prepared for distribution to customers worldwide. Stringent packaging standards are followed to ensure the integrity and safety of the products during transit, with proper labeling and documentation provided for easy identification and traceability.

In conclusion, the production of rubber fillers in China is a complex and meticulous process that involves careful selection of raw materials, precise manufacturing techniques, and rigorous quality control measures. Behind the scenes, in factories across the country, skilled professionals work tirelessly to deliver high-quality fillers that meet the diverse needs of industries ranging from automotive and construction to aerospace and healthcare. By adhering to stringent standards and embracing innovation, China continues to be a leading producer of rubber fillers, contributing to the advancement and success of global industries.