Table of Contents

Benefits of Stainless Steel Slitting in Metal Production

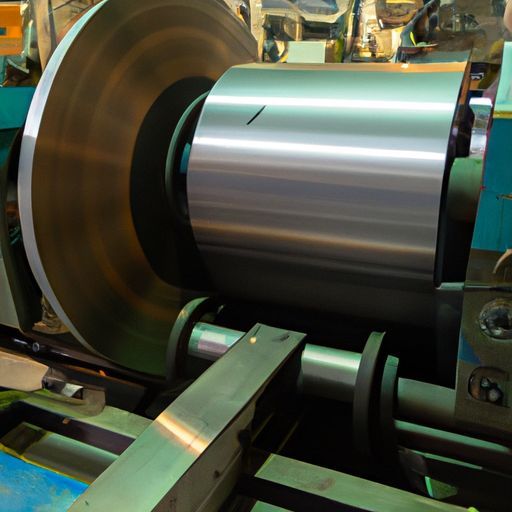

Stainless steel slitting is a crucial process in metal production that involves cutting large coils of stainless steel into narrower strips. This process is essential for various industries that require precision-cut Stainless Steel Strips for their manufacturing processes. The use of stainless steel slitting offers numerous benefits that contribute to the overall efficiency and quality of metal production.

One of the primary benefits of stainless steel slitting is the ability to produce strips of varying widths. This flexibility allows manufacturers to customize their products according to specific requirements, resulting in a more efficient and cost-effective production process. By having the capability to produce strips of different sizes, manufacturers can minimize waste and maximize the use of materials, ultimately reducing production costs.

In addition to flexibility in strip width, stainless steel slitting also ensures consistent strip thickness. This is crucial for industries that require uniformity in their products, such as the automotive and aerospace industries. Consistent strip thickness helps maintain product quality and performance, leading to higher customer satisfaction and increased demand for the finished products.

Another significant benefit of stainless steel slitting is the improved surface finish of the strips. The slitting process removes any imperfections or defects on the surface of the stainless steel, resulting in a smooth and polished finish. This not only enhances the aesthetic appeal of the finished products but also improves their corrosion resistance and durability.

Furthermore, stainless steel slitting helps increase production efficiency by reducing Lead times and turnaround times. With the ability to produce custom-sized strips quickly and accurately, manufacturers can meet tight deadlines and fulfill orders in a timely manner. This efficiency not only improves customer satisfaction but also enhances the overall competitiveness of the company in the market.

Moreover, stainless steel slitting is a cost-effective solution for manufacturers looking to optimize their production processes. By reducing waste and maximizing material utilization, companies can lower their production costs and improve their profit margins. Additionally, the improved quality and consistency of the stainless steel strips result in fewer defects and rework, further reducing production costs and increasing overall efficiency.

Overall, stainless steel slitting offers numerous benefits that contribute to the success of metal production industries. From increased flexibility and customization to improved quality and efficiency, the advantages of stainless steel slitting are undeniable. By investing in a high-quality stainless steel slitting Production Line, manufacturers can enhance their production processes, reduce costs, and stay ahead of the competition in today’s fast-paced market.