Table of Contents

Benefits of Name Dot Peen Pneumatic Metal Plate Engraving

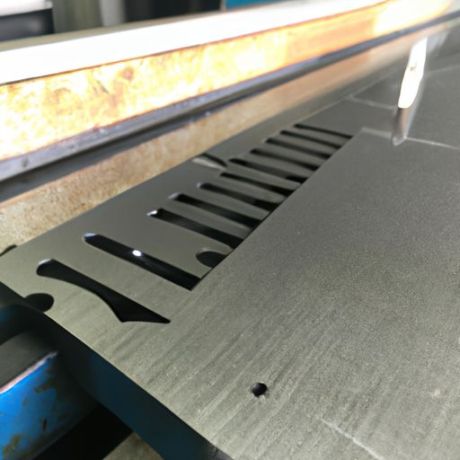

Name dot peen pneumatic metal plate engraving is a process that involves using a pneumatic engraving machine to create permanent markings on metal surfaces. This method is commonly used in industries such as manufacturing, aerospace, and automotive to mark parts and components with important information such as serial numbers, part numbers, and logos. There are several benefits to using name dot peen pneumatic metal plate engraving, which we will explore in this article.

One of the main advantages of name dot peen pneumatic metal plate engraving is its durability. The markings created using this method are deep and permanent, making them resistant to wear and tear. This is especially important in industries where parts and components are subjected to harsh conditions, as the markings will remain legible even after prolonged use.

In addition to durability, name dot peen pneumatic metal plate engraving offers high precision and accuracy. The pneumatic engraving machine uses a series of tiny dots to create the markings, resulting in clear and precise characters. This level of accuracy is crucial in industries where precision is key, as it ensures that the markings are legible and easy to read.

Another benefit of name dot peen pneumatic metal plate engraving is its versatility. The pneumatic engraving machine can be used on a wide range of metal surfaces, including Stainless Steel, Aluminum, and brass. This makes it a versatile solution for industries that work with different types of metals, as the same machine can be used to mark various materials.

Furthermore, name dot peen pneumatic metal plate engraving is a cost-effective solution for marking metal parts and components. The pneumatic engraving machine is easy to operate and requires minimal maintenance, reducing the overall cost of the marking process. Additionally, the markings created using this method are permanent, eliminating the need for frequent re-marking and reducing the overall cost of maintenance.

In conclusion, name dot peen pneumatic metal plate engraving offers several benefits for industries that require durable, precise, and cost-effective marking solutions. The durability of the markings, high precision and accuracy, versatility, and cost-effectiveness make this method an ideal choice for industries such as manufacturing, aerospace, and automotive. By investing in a pneumatic engraving machine for name dot peen metal plate engraving, businesses can ensure that their parts and components are marked with clear, permanent, and legible information.

How to Choose the Right Metal Mould Pneumatic Engraving Machine Dot

When it comes to metal plate engraving, one of the most popular methods is dot peen marking. This process involves using a pneumatic engraving machine to create permanent marks on metal surfaces. The dot peen method is known for its durability and precision, making it ideal for a wide range of applications, from industrial part marking to product branding.

Choosing the right metal mould pneumatic engraving machine dot is crucial to achieving the desired results. There are several factors to consider when selecting a machine, including the type of material you will be engraving, the size of the marks you need to make, and the level of automation required.

One of the first things to consider when choosing a metal mould pneumatic engraving machine dot is the type of material you will be working with. Different metals have different hardness Levels, which can affect the type of machine you need. For softer metals like aluminum or brass, a standard dot peen machine may be sufficient. However, for harder materials like stainless steel or Titanium, you may need a machine with higher impact force to create clear, deep marks.

Another important factor to consider is the size of the marks you need to make. Some dot peen machines are capable of creating very small, precise marks, while others are better suited for larger, more visible engravings. Consider the size of the text or design you will be marking, as well as the overall size of the metal surface, when choosing a machine.

Automation is another key consideration when selecting a metal mould pneumatic engraving machine dot. Some machines are fully manual, requiring the operator to move the engraving head by hand. Others are semi-automatic, with features like automatic depth control and programmable marking sequences. Fully automatic machines are also available, with advanced features like barcode scanning and data matrix coding. Consider the level of automation that will best suit your needs and budget.

In addition to these factors, it is important to consider the overall quality and reliability of the machine. Look for a reputable manufacturer with a track record of producing high-quality engraving machines. Read reviews and testimonials from other users to get an idea of the machine’s performance and durability.

Once you have considered all of these factors, you can begin to narrow Down your options and choose the right metal mould pneumatic engraving machine dot for your needs. Remember to take into account the type of material you will be engraving, the size of the marks you need to make, the level of automation required, and the overall quality of the machine.

https://www.youtube.com/watch?v=FdGOUdeUZMI

In conclusion, choosing the right metal mould pneumatic engraving machine dot is essential to achieving high-quality, durable marks on metal surfaces. Consider factors like material type, mark size, automation level, and machine quality when making your selection. With the right machine, you can create professional-looking engravings that will stand the test of time.