Table of Contents

Understanding the Role of Downhole Tool Casing Scraper in Oil Well Drilling Rig Equipment

Oil well drilling rigs are complex systems comprising various equipment and tools designed to extract Crude Oil efficiently and safely from underground reservoirs. Among the array of components used in this process, downhole tool casing scrapers play a crucial role in ensuring the integrity and functionality of oil wells. These specialized tools are instrumental in maintaining the cleanliness of the well casing, preventing potential issues that could impede the drilling process or compromise the productivity of the well.

In the context of oil drilling, the casing serves as a protective barrier that lines the wellbore, providing structural support and preventing the collapse of the surrounding geological formations. Over time, however, the casing can accumulate debris, such as mud, scale, or Cement, which may obstruct the flow of oil or hinder the movement of downhole tools. This accumulation can Lead to reduced efficiency, increased wear and tear on equipment, and even complete wellbore blockages if left unchecked.

This is where downhole tool casing scrapers come into play. These tools are designed to remove built-up debris from the inner walls of the casing, ensuring a clear pathway for the drilling operation. By scraping away accumulated materials, casing scrapers help maintain optimal wellbore conditions, allowing for smooth drilling operations and maximizing the productivity of the well.

The importance of downhole tool casing scrapers becomes particularly evident in challenging drilling environments, such as those characterized by high temperatures, high pressures, or abrasive formations. In such conditions, the risk of debris buildup is heightened, posing significant operational risks and increasing the likelihood of equipment failure. By employing casing scrapers, operators can mitigate these risks and enhance the overall efficiency and Safety of the drilling process.

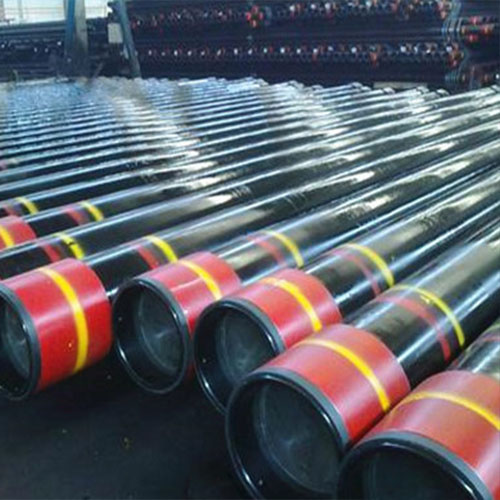

One of the key advantages of downhole tool casing scrapers is their versatility and adaptability to various wellbore conditions. These tools come in a range of sizes and configurations to accommodate different casing diameters and types of debris. Whether the casing is clogged with hardened mud, scale, or other obstructions, there is a suitable scraper available to effectively clean the inner walls and restore optimal flow conditions.

Furthermore, downhole tool casing scrapers are designed to withstand the harsh operating conditions encountered in oil well drilling. Constructed from durable materials such as hardened steel or Tungsten carbide, these tools exhibit excellent wear resistance and longevity, ensuring reliable performance even in the most demanding environments. Additionally, many casing scrapers are equipped with features such as spring-loaded Blades or rotating brushes to enhance their cleaning effectiveness and efficiency.

In conclusion, downhole tool casing scrapers play a vital role in the operation of oil well drilling rigs by ensuring the cleanliness and integrity of the well casing. By removing debris and obstructions from the inner walls of the casing, these specialized tools help maintain optimal flow conditions, minimize equipment downtime, and maximize the productivity of oil wells. With their versatility, durability, and effectiveness, casing scrapers are indispensable components of drilling operations, contributing to the efficient and safe extraction of crude oil from underground reservoirs.

Exploring API Standards and Their Significance in Oil Well Drilling Rig Equipment Tools

Oil well drilling rig equipment tools play a crucial role in the extraction of oil and gas from beneath the Earth’s surface. Among these tools, downhole tools such as casing scrapers are essential for maintaining the integrity of the wellbore and ensuring efficient production. In the oil and gas industry, adherence to standards is paramount to safety, reliability, and interoperability. The American Petroleum Institute (API) has established standards that govern various aspects of oil well drilling rig equipment tools, including downhole tools like casing scrapers.

API standards are developed through a consensus-based process involving industry experts, regulators, and other stakeholders. These standards are designed to ensure that oil well drilling rig equipment tools meet stringent requirements for performance, safety, and environmental protection. By adhering to API standards, manufacturers can demonstrate the quality and reliability of their products, while operators can have confidence in the equipment they use in their drilling operations.

One of the key API standards related to downhole tools is API Specification 5CT, which covers the specifications for casing and tubing used in oil and gas wells. This standard defines the technical requirements for casing scrapers, including dimensions, materials, and performance characteristics. Casing scrapers are used to remove debris, scale, and other obstructions from the inside of the casing, ensuring proper cementing and completion of the well.

API Specification 5CT also establishes requirements for the threading and coupling of casing and tubing connections, ensuring compatibility and integrity in the downhole Environment. By adhering to these standards, manufacturers can produce casing scrapers that are compatible with a wide range of wellbore conditions and drilling techniques, providing operators with greater flexibility and reliability.

In addition to API Specification 5CT, there are other API standards that are relevant to downhole tools and equipment, such as API Specification 7-1 for rotary drilling equipment and API Specification 6A for wellhead and Christmas tree equipment. These standards cover a wide range of equipment used in oil and gas drilling operations, from Drill Bits and drilling jars to blowout preventers and Valves.

The significance of API standards in oil well drilling rig equipment tools cannot be overstated. By providing a common set of technical requirements and testing procedures, these standards enable interoperability among different manufacturers’ products and ensure the safety and reliability of drilling operations. Furthermore, API standards are recognized and adopted by regulators around the world, providing a benchmark for compliance and quality assurance.

In conclusion, API standards play a critical role in the design, manufacturing, and operation of oil well drilling rig equipment tools, including downhole tools like casing scrapers. By adhering to these standards, manufacturers can demonstrate the quality and reliability of their products, while operators can have confidence in the equipment they use in their drilling operations. As the oil and gas industry continues to evolve, adherence to API standards will remain essential for ensuring safety, efficiency, and environmental protection in drilling operations around the world.