Table of Contents

The Importance of Quality Control in Oil Country Tubular Goods Manufacturing

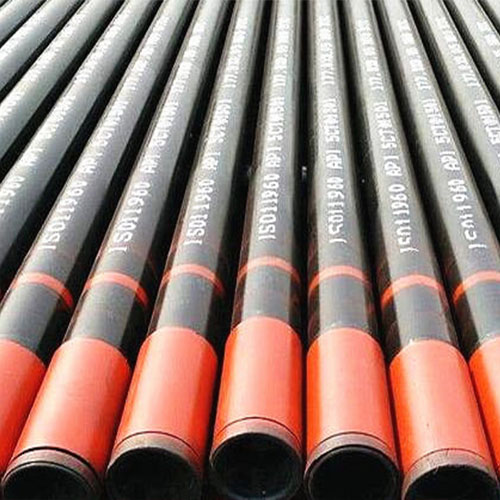

Oil Country Tubular Goods (OCTG) play a crucial role in the oil and gas industry, serving as the primary components for drilling and extracting oil and gas from the earth. OCTG includes casing, tubing, and drill pipes, which are essential for maintaining the integrity of oil and gas wells. Given the critical nature of these products, quality control is of utmost importance in the manufacturing process.

Quality control in OCTG manufacturing involves a series of rigorous tests and inspections to ensure that the products meet industry standards and specifications. These tests are designed to detect any defects or imperfections that could compromise the performance and Safety of the OCTG. By adhering to strict quality control measures, manufacturers can produce high-quality products that meet the demands of the oil and gas industry.

One of the key aspects of quality control in OCTG manufacturing is material testing. This involves analyzing the chemical composition and mechanical properties of the raw materials used to make the OCTG. By conducting material testing, manufacturers can ensure that the materials meet the required specifications for strength, durability, and corrosion resistance. This is essential for ensuring the reliability and longevity of the OCTG in harsh drilling environments.

In addition to material testing, dimensional inspection is another critical aspect of quality control in OCTG manufacturing. This involves verifying the dimensions and tolerances of the OCTG products to ensure they meet the specified requirements. Dimensional inspection helps to prevent issues such as misalignment, leakage, and mechanical failure, which can have serious consequences for drilling operations.

Furthermore, non-destructive testing (NDT) is an essential part of quality control in OCTG manufacturing. NDT techniques such as ultrasonic testing, magnetic particle testing, and visual inspection are used to detect surface and subsurface defects in the OCTG products. By identifying and addressing defects early on, manufacturers can prevent costly failures and ensure the safety and reliability of the products.

Another important aspect of quality control in OCTG manufacturing is traceability. Traceability involves tracking the production process from raw materials to finished products, ensuring that each step meets the required standards. By maintaining detailed records of materials, processes, and inspections, manufacturers can quickly identify and address any issues that may arise during production.

In conclusion, quality control is essential in OCTG manufacturing to ensure the safety, reliability, and performance of the products. By implementing rigorous testing and inspection procedures, manufacturers can produce high-quality OCTG that meet industry standards and specifications. Quality control measures such as material testing, dimensional inspection, NDT, and traceability are crucial for maintaining the integrity of oil and gas wells and preventing costly failures. Ultimately, investing in quality control in OCTG manufacturing is essential for the success of the oil and gas industry.

The Future of Oil Country Tubular Goods in the Energy Industry

Oil Country Tubular Goods (OCTG) play a crucial role in the energy industry, particularly in the extraction and transportation of oil and gas. OCTG refers to a group of seamless rolled products used in the drilling and completion of oil and gas wells. This includes casing, tubing, and drill pipes, among other components. As the energy industry continues to evolve, the demand for OCTG is expected to grow, driven by factors such as increasing global energy consumption and the development of new oil and gas reserves.

Casing and tubing are two of the most important components of OCTG. Casing is used to line the walls of a wellbore to prevent collapse and to ensure that the drilling fluid is contained within the well. Tubing, on the other hand, is used to transport oil and gas from the well to the surface. Both casing and tubing are subject to harsh operating conditions, including high pressure, high temperature, and corrosive environments. As a result, OCTG must be manufactured to meet stringent quality and performance standards to ensure the safety and efficiency of oil and gas operations.

https://www.youtube.com/watch?v=6tUfn1bKo9YThe future of OCTG in the energy industry looks promising, with several key trends shaping the market. One of the most significant trends is the increasing demand for oil and gas, driven by population growth, urbanization, and industrialization. As developing countries continue to industrialize and modernize, the demand for energy is expected to rise, leading to increased drilling activity and the need for OCTG. In addition, the development of new oil and gas reserves, particularly in unconventional shale plays, is driving the demand for OCTG as operators seek to maximize production and recoverable reserves.

Another important trend in the OCTG market is the focus on sustainability and environmental responsibility. As concerns about climate change and environmental degradation grow, the energy industry is under increasing pressure to reduce its carbon footprint and adopt more sustainable practices. This includes the use of advanced technologies and materials in OCTG manufacturing to improve efficiency, reduce emissions, and minimize environmental impact. In response to these trends, manufacturers are investing in research and development to develop new, eco-friendly materials and processes for OCTG production.

Advancements in technology are also driving the future of OCTG in the energy industry. Innovations such as digitalization, automation, and data analytics are revolutionizing oil and gas operations, leading to increased efficiency, productivity, and safety. For example, digital technologies can be used to monitor and optimize well performance in real-time, leading to better decision-making and improved production outcomes. Similarly, automation can streamline drilling and completion processes, reducing costs and increasing operational efficiency. These technological advancements are expected to drive the demand for high-performance OCTG that can withstand the rigors of modern drilling operations.

In conclusion, the future of Oil Country Tubular Goods in the energy industry looks bright, with increasing demand, sustainability concerns, and technological advancements driving market growth. As the energy industry continues to evolve, OCTG will play a critical role in ensuring the safety, efficiency, and sustainability of oil and gas operations. Manufacturers and operators must continue to innovate and collaborate to develop new solutions that meet the challenges of the future and support the transition to a more sustainable energy future. By investing in research, development, and innovation, the OCTG industry can continue to thrive and contribute to the success of the energy industry as a whole.