Table of Contents

Benefits of Using a Multi-Station Winding Machine for Low Voltage Manufacturing Equipment

In the world of manufacturing, efficiency and precision are key factors in ensuring the success of a Production Line. One crucial aspect of manufacturing equipment is the stator Coil Winding Machine, which is used to wind coils for Electric Motors. In recent years, there has been a shift towards using multi-station Winding Machines for low voltage manufacturing equipment, as they offer a range of benefits that can greatly improve the efficiency and quality of the production process.

In the world of manufacturing, efficiency and precision are key factors in ensuring the success of a Production Line. One crucial aspect of manufacturing equipment is the stator Coil Winding Machine, which is used to wind coils for Electric Motors. In recent years, there has been a shift towards using multi-station Winding Machines for low voltage manufacturing equipment, as they offer a range of benefits that can greatly improve the efficiency and quality of the production process.

One of the main advantages of using a multi-station winding machine is the ability to increase production output. These machines are designed to wind multiple coils simultaneously, which can significantly reduce the time it takes to complete a batch of coils. This increased efficiency can Lead to higher production volumes and faster turnaround times, ultimately improving the overall productivity of the manufacturing line.

Another benefit of using a multi-station winding machine is the improved consistency and accuracy of the coils produced. By winding multiple coils at the same time, the machine ensures that each coil is wound to the exact specifications required, resulting in a more uniform and reliable end product. This level of precision is crucial in industries where quality control is paramount, such as in the production of electronic devices or automotive components.

In addition to improving production output and quality, multi-station winding machines also offer a higher level of automation compared to traditional single-station machines. These machines are equipped with advanced control systems that allow for easy programming and monitoring of the winding process. This automation not only reduces the need for manual intervention but also minimizes the risk of human error, resulting in a more consistent and reliable production process.

Furthermore, multi-station winding machines are designed to be versatile and adaptable to different production requirements. These machines can be easily reconfigured to accommodate different coil sizes and winding patterns, making them suitable for a wide range of applications. This flexibility allows manufacturers to quickly adjust their production processes to meet changing market demands, without the need for costly equipment upgrades or replacements.

Overall, the use of a multi-station winding machine for low voltage manufacturing equipment offers a range of benefits that can greatly improve the efficiency, quality, and flexibility of the production process. By increasing production output, improving consistency and accuracy, and providing a higher level of automation, these machines are an essential tool for manufacturers looking to stay competitive in today’s fast-paced industry. Whether used in the production of electric motors, Transformers, or other electrical components, a multi-station winding machine is a valuable investment that can help drive success and growth in the manufacturing sector.

How to Increase Efficiency with an Automatic Stator Coil Winding Machine for High-Speed Motor Stator Production

In the manufacturing industry, efficiency is key to staying competitive and meeting customer demands. One way to increase efficiency in the production of high-speed motor stators is by using an automatic stator coil winding machine. These machines are designed to streamline the winding process, reducing labor costs and improving overall productivity.

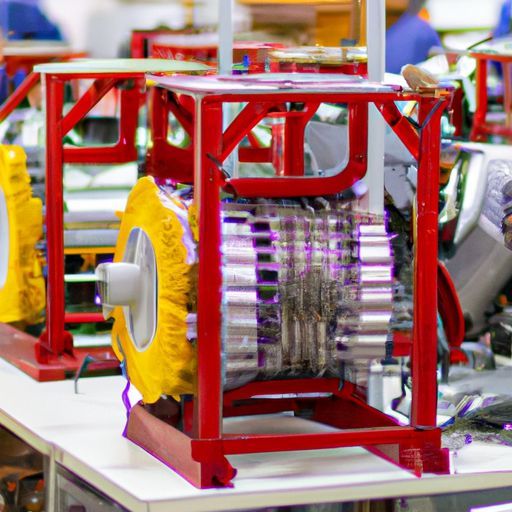

The multi-station winding machine fan motor for low voltage manufacturing equipment is a prime example of an automatic stator coil winding machine that can significantly increase efficiency in stator production. This machine is equipped with multiple winding stations, allowing for simultaneous winding of multiple coils. This not only speeds up the production process but also ensures consistency in the winding of each coil.

By automating the winding process, manufacturers can reduce the risk of human error and improve the quality of the final product. Automatic stator coil winding machines are programmed to wind coils to precise specifications, ensuring that each coil meets the required standards for performance and reliability.

In addition to improving quality, automatic stator coil winding machines also help to reduce waste. By accurately controlling the amount of wire used in each coil, these machines minimize material waste and help to optimize the use of resources. This can result in cost savings for manufacturers and a more sustainable production process.

Another key benefit of using an automatic stator coil winding machine is the ability to increase production capacity. These machines are capable of winding coils at a much faster rate than manual winding, allowing manufacturers to meet higher demand without sacrificing quality. This can be especially important in industries where production volumes fluctuate or where quick turnaround times are required.

The high-speed motor stator produced by automatic stator coil winding machines is also more reliable and durable than manually wound stators. The precise winding process ensures that each coil is uniform and tightly wound, reducing the risk of Shorts or other electrical faults. This can result in a longer lifespan for the motor and improved performance in the end product.

Overall, investing in an automatic stator coil winding machine for high-speed motor stator production can have a significant impact on efficiency and productivity. These machines offer a range of benefits, from improved quality and consistency to reduced waste and increased production capacity. By automating the winding process, manufacturers can streamline their operations and stay ahead of the competition in today’s fast-paced manufacturing Environment.

In conclusion, automatic stator coil winding machines are a valuable tool for increasing efficiency in the production of high-speed motor stators. These machines offer a range of benefits, from improved quality and consistency to reduced waste and increased production capacity. By investing in this technology, manufacturers can optimize their production processes and stay competitive in today’s market.