Table of Contents

Benefits of Using Metal Sheet Television Back Cover/Plate Production

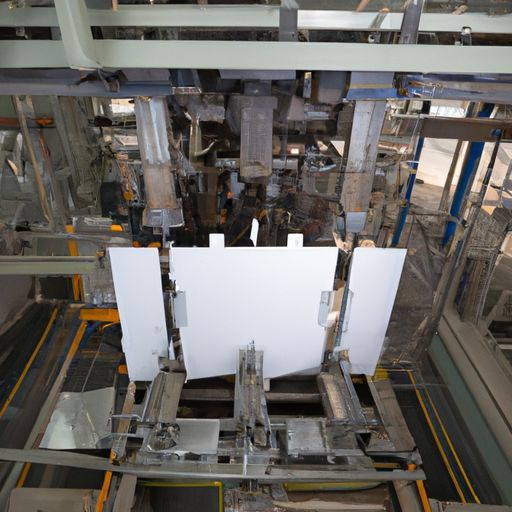

Metal sheet television back cover/plate production is an essential process in the manufacturing of televisions. One of the key components in this process is the continuous hot dip galvanizing line stamping power pressing machine. This machine plays a crucial role in shaping and forming metal sheets into the desired back cover or plate for televisions.

One of the primary benefits of using a continuous hot dip galvanizing line stamping power pressing machine is its efficiency. This machine is designed to work continuously, allowing for high-speed production of metal sheets. This means that manufacturers can produce a large number of back covers or plates in a short amount of time, increasing overall productivity and reducing production costs.

In addition to its efficiency, the continuous hot dip galvanizing line stamping power pressing machine also ensures precision and accuracy in the production process. The machine is equipped with advanced technology that allows for precise shaping and forming of metal sheets, resulting in high-quality back covers or plates that meet the exact specifications required for televisions.

Furthermore, using a continuous hot dip galvanizing line stamping power pressing machine can help manufacturers improve the durability and longevity of their products. The galvanizing process involves coating metal sheets with a layer of Zinc, which helps protect the metal from corrosion and rust. This means that back covers or plates produced using this machine are more resistant to wear and tear, ensuring that televisions have a longer lifespan.

Another benefit of using a continuous hot dip galvanizing line stamping power pressing machine is its versatility. This machine can be used to produce back covers or plates of various sizes and shapes, making it suitable for a wide range of television models. Manufacturers can easily adjust the settings of the machine to accommodate different specifications, allowing for greater flexibility in production.

Additionally, the continuous hot dip galvanizing line stamping power pressing machine is easy to operate and maintain. The machine is designed with user-friendly controls and features that make it simple for operators to set up and run production processes. Regular maintenance of the machine is also straightforward, ensuring that it remains in optimal working condition for long-term use.

Overall, the use of a continuous hot dip galvanizing line stamping power pressing machine in metal sheet television back cover/plate production offers numerous benefits for manufacturers. From increased efficiency and precision to improved durability and versatility, this machine plays a crucial role in the production of high-quality television components. By investing in this advanced technology, manufacturers can enhance their production processes and deliver superior products to consumers.