Table of Contents

Benefits of Using LDPE Recycled Granules in Manufacturing

In today’s world, the importance of sustainability and environmental responsibility cannot be overstated. As consumers become more conscious of the impact their purchasing decisions have on the planet, businesses are also looking for ways to reduce their carbon footprint and minimize waste. One way that manufacturers can contribute to a more sustainable future is by using LDPE recycled granules in their production processes.

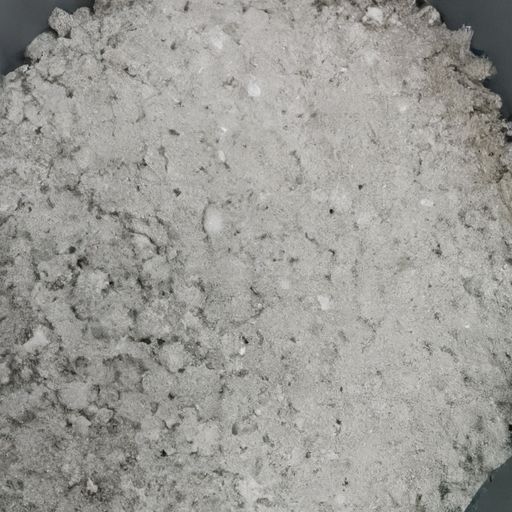

LDPE, or low-density polyethylene, is a versatile plastic material that is commonly used in a wide range of products, from packaging materials to household goods. By Recycling LDPE and turning it into granules that can be used as raw material in manufacturing, companies can reduce the amount of plastic waste that ends up in landfills or oceans. This not only helps to conserve valuable resources but also reduces the environmental impact of producing new plastic materials.

One of the key benefits of using LDPE recycled granules in manufacturing is that it can help companies save money. Recycled Plastic materials are often less expensive than virgin plastics, making them a cost-effective alternative for businesses looking to reduce their production costs. By using LDPE recycled granules, manufacturers can lower their overall expenses without compromising on the quality of their products.

In addition to cost savings, using LDPE recycled granules can also help companies meet their sustainability goals. Many consumers today are looking for products that are made from recycled materials and are environmentally friendly. By incorporating recycled plastic into their manufacturing processes, companies can appeal to eco-conscious consumers and enhance their brand reputation as a socially responsible business.

Furthermore, LDPE recycled granules offer the same level of quality and performance as virgin plastics. Recycled plastic materials undergo a thorough cleaning and processing process to ensure that they meet the same standards as new plastic materials. This means that manufacturers can use LDPE recycled granules with confidence, knowing that they will not compromise the integrity or durability of their products.

Another benefit of using LDPE recycled granules in manufacturing is that it can help companies reduce their carbon footprint. Producing new plastic materials from raw petroleum resources requires a significant amount of energy and generates greenhouse gas emissions. By using recycled plastic materials, companies can reduce their reliance on fossil fuels and lower their overall carbon emissions.

In conclusion, the benefits of using LDPE recycled granules in manufacturing are clear. From cost savings to environmental sustainability, recycled plastic materials offer a range of advantages for businesses looking to reduce their impact on the planet. By incorporating LDPE recycled granules into their production processes, companies can not only save money but also appeal to eco-conscious consumers and contribute to a more sustainable future. As the demand for environmentally friendly products continues to grow, using recycled plastic materials like LDPE granules can help companies stay ahead of the curve and demonstrate their commitment to sustainability.

How to Source High Quality Low Price LDPE Recycled Granules for Production

Low-density polyethylene (LDPE) is a versatile material that is commonly used in the production of various Plastic Products. It is known for its flexibility, durability, and resistance to moisture, making it a popular choice for packaging materials, Containers, and other consumer goods. However, the production of LDPE can have a significant impact on the Environment, as it is derived from non-renewable fossil fuels. As a result, there is a growing demand for recycled LDPE granules, which offer a more sustainable alternative to virgin plastic.

Sourcing high-quality low-price LDPE recycled granules for production can be a challenging task, as there are many factors to consider. One of the most important considerations is the quality of the recycled material. Recycled LDPE granules can vary widely in quality, depending on the source of the material and the recycling process used. It is essential to ensure that the recycled granules meet the required specifications for your production needs, as using substandard material can result in inferior products and production issues.

When sourcing LDPE recycled granules, it is crucial to work with reputable suppliers who can provide consistent quality and reliable supply. Look for suppliers who have a proven track record in the recycling industry and who adhere to strict quality control standards. It is also essential to consider the price of the recycled granules, as cost is a significant factor in production decisions. While it is important to find a supplier who offers competitive pricing, it is equally important to ensure that the quality of the material is not compromised in the pursuit of lower costs.

One way to source high-quality low-price LDPE recycled granules is to work with recycling facilities that specialize in LDPE recycling. These facilities have the expertise and equipment necessary to process LDPE waste into high-quality recycled granules that meet industry standards. By partnering with a recycling facility, you can ensure a reliable supply of recycled material that meets your production requirements. Additionally, working with a recycling facility can help support the circular economy by diverting LDPE waste from landfills and reducing the environmental impact of plastic production.

Another option for sourcing LDPE recycled granules is to work with brokers or traders who specialize in the sale of recycled plastics. These intermediaries have established networks of suppliers and can help connect you with sources of high-quality recycled granules at competitive prices. By working with a broker or trader, you can access a wider range of suppliers and negotiate favorable terms for your purchase. However, it is essential to conduct due diligence on any potential suppliers to ensure that they meet your quality and sustainability standards.

In conclusion, sourcing high-quality low-price LDPE recycled granules for production requires careful consideration of quality, price, and sustainability factors. By working with reputable suppliers, recycling facilities, or brokers, you can access a reliable supply of recycled material that meets your production needs. By choosing recycled LDPE granules, you can reduce your environmental impact and support the transition to a more sustainable plastic economy.