Table of Contents

Advantages of Using Fixed Resistor Carbon Film Resistors

Fixed resistor carbon film resistors are a popular choice in electronic circuits due to their numerous advantages. These resistors are designed to provide a stable and precise resistance value, making them ideal for a wide range of applications. In this article, we will explore the advantages of using fixed resistor carbon film resistors in electronic circuits.

One of the key advantages of fixed resistor carbon film resistors is their high precision. These resistors are manufactured to tight tolerances, typically within 5%, ensuring that the resistance value remains consistent over time. This level of precision is essential in electronic circuits where accurate resistance values are required for proper operation.

In addition to their precision, fixed resistor carbon film resistors are also known for their stability. These resistors are designed to withstand changes in temperature and humidity, making them suitable for use in a variety of environmental conditions. This stability ensures that the resistance value of the resistor remains constant, even in harsh operating conditions.

Another advantage of fixed resistor carbon film resistors is their reliability. These resistors are constructed using high-quality materials that are resistant to wear and tear, ensuring a long lifespan. This reliability is crucial in electronic circuits where the failure of a single component can Lead to system failure.

Fixed resistor carbon film resistors are also known for their low noise and low inductance characteristics. These resistors produce minimal noise when current flows through them, making them ideal for use in audio applications where noise interference can be a concern. Additionally, the low inductance of these resistors ensures that they do not introduce unwanted electromagnetic interference into the circuit.

Furthermore, fixed resistor carbon film resistors are easy to install and replace. These resistors are available in a variety of package sizes and lead configurations, making them compatible with a wide range of circuit designs. Additionally, their standardized color-coding system makes it easy to identify the resistance value of the resistor, simplifying the installation process.

Overall, fixed resistor carbon film resistors offer a range of advantages that make them a popular choice in electronic circuits. Their high precision, stability, reliability, low noise, and low inductance characteristics make them ideal for a wide range of applications. Additionally, their ease of installation and replacement further enhance their appeal to electronics designers and hobbyists.

In conclusion, fixed resistor carbon film resistors are a versatile and reliable component that can enhance the performance of electronic circuits. Their numerous advantages make them a popular choice among electronics designers looking for precision, stability, and reliability in their designs. Whether used in audio applications, Power Supplies, or control systems, fixed resistor carbon film resistors are sure to deliver consistent and accurate resistance values for years to come.

In conclusion, fixed resistor carbon film resistors are a versatile and reliable component that can enhance the performance of electronic circuits. Their numerous advantages make them a popular choice among electronics designers looking for precision, stability, and reliability in their designs. Whether used in audio applications, Power Supplies, or control systems, fixed resistor carbon film resistors are sure to deliver consistent and accurate resistance values for years to come.

How to Choose the Right Fixed Resistor Carbon Film Resistor for Your Project

When it comes to choosing the right fixed resistor for your project, there are several factors to consider. One popular option is the carbon film resistor, which is known for its reliability and stability. In this article, we will discuss the features of the fixed resistor carbon film resistor and provide some tips on how to choose the right one for your specific needs.

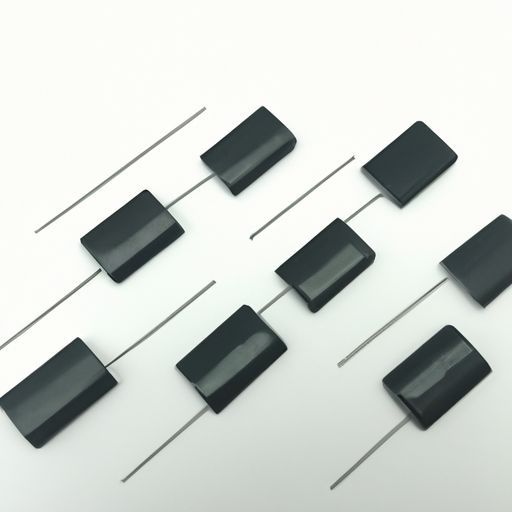

Carbon film resistors are a type of fixed resistor that is made by depositing a thin film of carbon onto a ceramic substrate. This carbon film is then coated with a protective layer to prevent damage from moisture and other environmental factors. The result is a resistor that is both durable and stable, making it ideal for a wide range of applications.

One of the key features of carbon film resistors is their resistance tolerance, which is typically around 5%. This means that the actual resistance of the resistor may vary slightly from the stated value, but this variation is within an acceptable range for most applications. In addition, carbon film resistors are available in a wide range of resistance values, from 1 ohm to 9.1 ohms, making them suitable for a variety of projects.

When choosing a carbon film resistor for your project, it is important to consider the power rating of the resistor. This is typically measured in watts, and it indicates the maximum amount of power that the resistor can safely dissipate without overheating. For most applications, a 500mW resistor should be sufficient, but it is always a good idea to check the power requirements of your specific project to ensure that you choose a resistor with the appropriate power rating.

Another important factor to consider when choosing a carbon film resistor is its moisture resistance. Since these resistors are often used in environments where moisture may be present, such as in outdoor or industrial applications, it is important to choose a resistor that is designed to withstand these conditions. Look for resistors that are labeled as moisture resistant or have a protective coating to ensure that they will not be damaged by exposure to moisture.

In addition to resistance tolerance, power rating, and moisture resistance, there are a few other factors to consider when choosing a carbon film resistor. One important consideration is the temperature coefficient of the resistor, which indicates how much the resistance of the resistor will change with changes in temperature. For most applications, a resistor with a low temperature coefficient is preferable, as it will provide more stable performance over a wide range of temperatures.

It is also important to consider the size and shape of the resistor, as this will determine how easily it can be mounted on a circuit board or in an enclosure. Carbon film resistors are typically available in a standard axial lead package, which is easy to solder onto a circuit board. However, if space is limited, you may want to consider a surface mount resistor, which can be mounted directly onto the surface of a circuit board.

In conclusion, carbon film resistors are a reliable and stable option for a wide range of applications. By considering factors such as resistance tolerance, power rating, moisture resistance, temperature coefficient, and package size, you can choose the right carbon film resistor for your specific project. Whether you are building a simple electronic circuit or a complex industrial control system, a carbon film resistor can provide the precision and reliability you need.