Table of Contents

Benefits of Using Feeder Original Used 5 Tube for Yamaha YV100II Feeder

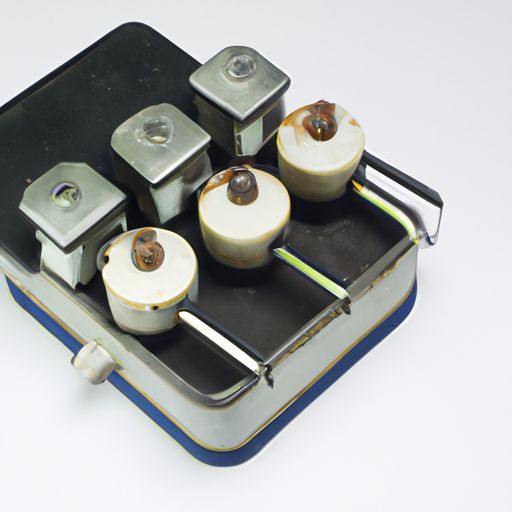

Feeder Original Used 5 Tube for Yamaha YV100II Feeder is a crucial component in the pick and place machine for the Yamaha YV Series SMT Stick Vibration. This feeder is designed to efficiently feed components into the machine, ensuring smooth and accurate placement during the assembly process. There are several benefits to using Feeder Original Used 5 Tube for Yamaha YV100II Feeder, which we will explore in this article.

One of the main advantages of using Feeder Original Used 5 Tube for Yamaha YV100II Feeder is its reliability. This feeder is made from high-quality materials and is designed to withstand the rigors of continuous use in a manufacturing Environment. This means that you can rely on this feeder to consistently feed components into the pick and place machine without any issues, ensuring that your production process runs smoothly and efficiently.

One of the main advantages of using Feeder Original Used 5 Tube for Yamaha YV100II Feeder is its reliability. This feeder is made from high-quality materials and is designed to withstand the rigors of continuous use in a manufacturing Environment. This means that you can rely on this feeder to consistently feed components into the pick and place machine without any issues, ensuring that your production process runs smoothly and efficiently.

Another benefit of using Feeder Original Used 5 Tube for Yamaha YV100II Feeder is its compatibility with the Yamaha YV Series SMT Stick Vibration. This feeder is specifically designed to work seamlessly with this machine, ensuring optimal performance and accuracy during the assembly process. By using a feeder that is specifically designed for your machine, you can avoid compatibility issues and ensure that your production process runs smoothly.

In addition to its reliability and compatibility, Feeder Original Used 5 Tube for Yamaha YV100II Feeder also offers excellent performance. This feeder is designed to feed components quickly and accurately into the pick and place machine, ensuring that each component is placed in the correct position with precision. This level of performance is crucial in the manufacturing process, as even small errors in component placement can Lead to defects in the final product.

Furthermore, using Feeder Original Used 5 Tube for Yamaha YV100II Feeder can also help to improve the overall efficiency of your production process. By ensuring that components are fed into the pick and place machine quickly and accurately, this feeder can help to reduce downtime and increase the overall throughput of your Production Line. This can ultimately lead to cost savings and improved productivity, making this feeder a valuable investment for any manufacturing operation.

Overall, Feeder Original Used 5 Tube for Yamaha YV100II Feeder offers a range of benefits for manufacturers looking to improve the performance and efficiency of their production process. From its reliability and compatibility with the Yamaha YV Series SMT Stick Vibration to its excellent performance and ability to improve overall efficiency, this feeder is a valuable tool for any manufacturing operation. By investing in Feeder Original Used 5 Tube for Yamaha YV100II Feeder, you can ensure that your production process runs smoothly and efficiently, leading to improved quality and productivity in your manufacturing operation.

How to Properly Maintain and Troubleshoot Yamaha Stick Feeder for Pick and Place Machine YAMAHA YV Series SMT Stick Vibration

Feeder Original Used 5 Tube for Yamaha YV100II Feeder Yamaha Stick Feeder for Pick and Place Machine YAMAHA YV Series SMT Stick Vibration is an essential component in the smooth operation of pick and place machines. These stick feeders are designed to hold and dispense components onto the PCB with precision and accuracy. However, like any other machine component, they require proper maintenance and troubleshooting to ensure optimal performance.

One of the key aspects of maintaining Yamaha stick feeders is regular cleaning. Dust, debris, and residue can accumulate inside the feeder tubes, causing jams and misfeeds. To prevent this, it is important to clean the feeder tubes regularly using a soft brush or compressed air. This will help to keep the tubes clear and free from any obstructions that could hinder the smooth flow of components.

In addition to cleaning, it is also important to inspect the feeder tubes for any signs of wear or damage. Over time, the tubes can become worn or bent, which can affect the alignment and feeding of components. If any damage is detected, it is important to replace the feeder tubes promptly to prevent any further issues.

Another common issue with Yamaha stick feeders is misalignment. If the feeder tubes are not properly aligned with the pick and place head, components may not be dispensed accurately onto the PCB. To troubleshoot this issue, it is important to check the alignment of the feeder tubes and adjust them as needed. This can usually be done by loosening the mounting Screws and repositioning the feeder tubes until they are aligned correctly.

In some cases, Yamaha stick feeders may also experience issues with component jamming. This can occur if components become stuck inside the feeder tubes or if there is a blockage in the feeder mechanism. To troubleshoot this issue, it is important to carefully inspect the feeder tubes and remove any obstructions that may be causing the Jam. Additionally, checking the feeder mechanism for any signs of wear or damage can help to prevent future jams from occurring.

It is also important to regularly calibrate Yamaha stick feeders to ensure accurate component placement. Calibration involves adjusting the feeder settings to match the size and shape of the components being dispensed. This can help to prevent misfeeds and ensure that components are placed correctly onto the PCB. If calibration is not done regularly, it can lead to issues with component placement and overall machine performance.

Overall, proper maintenance and troubleshooting of Yamaha stick feeders are essential for ensuring the smooth operation of pick and place machines. By regularly cleaning, inspecting, and calibrating the feeders, you can prevent issues such as misalignment, jamming, and inaccurate component placement. Taking the time to properly maintain and troubleshoot Yamaha stick feeders will help to prolong their lifespan and ensure optimal performance in your SMT assembly process.