Table of Contents

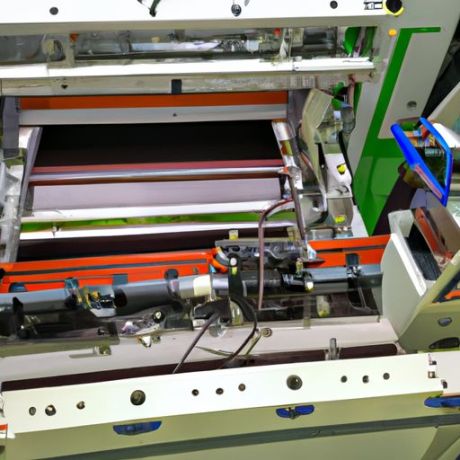

Large Capacity Cutting Machine

A cord tipping machine is an essential piece of equipment in the production of various types of Cords and ropes. These machines are designed to apply a tipping material, such as plastic or metal, to the ends of cords to prevent fraying and make them easier to handle. One of the key features of a cord tipping machine is its large capacity cutting capabilities, which allow for efficient and high-volume production.

Large capacity cutting machines are equipped with powerful cutting Blades that can easily slice through thick cords and ropes. This makes them ideal for processing heavy-duty materials and producing cords of varying thicknesses. The cutting process is automated, which ensures precision and consistency in the length of the cords being produced.

In addition to their cutting capabilities, large capacity cutting machines are also equipped with automatic production lines that streamline the manufacturing process. These production lines are designed to handle multiple tasks simultaneously, such as cutting, tipping, and packaging cords. This automation not only increases efficiency but also reduces the risk of human error, resulting in higher quality products.

There are various models of cord tipping machines available on the market, each with its own unique features and capabilities. Some models are designed for specific types of cords, such as round cords or flat cords, while others are more versatile and can handle a wide range of materials. The choice of model will depend on the specific needs of the manufacturer and the type of cords being produced.

One of the key advantages of using a large capacity cutting machine is the ability to increase production output. These machines are capable of processing a large volume of cords in a short amount of time, which is essential for meeting high demand and tight deadlines. This increased efficiency can also Lead to cost savings for manufacturers, as it reduces the need for manual labor and minimizes waste.

Another benefit of using a cord tipping machine is the improved quality of the finished product. The automated cutting process ensures that each cord is cut to the exact length required, resulting in uniformity and consistency across the entire production run. Additionally, the tipping material is applied with precision, ensuring a secure and durable finish that will withstand wear and tear.

In conclusion, large capacity cutting machines are an essential tool for manufacturers in the cord and Rope industry. These machines offer a range of benefits, including increased production output, improved quality, and cost savings. With their automated production lines and versatile capabilities, cord tipping machines are a valuable investment for any manufacturer looking to streamline their production process and deliver high-quality products to their customers.