Table of Contents

Benefits of Using Coffee Sachet Powder Filling Machines

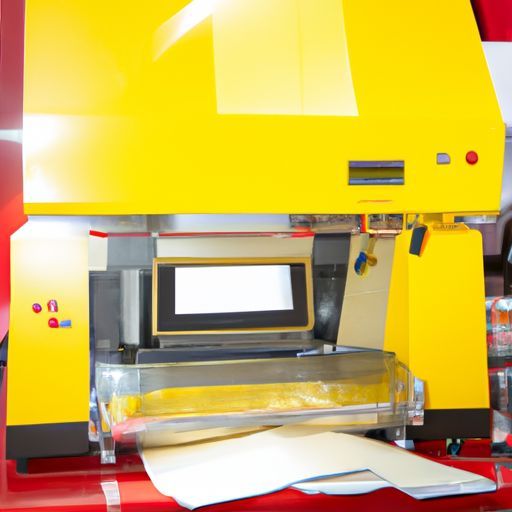

Coffee sachet powder filling machines are a crucial piece of equipment for businesses in the Food And Beverage industry. These machines offer a wide range of benefits that can help streamline production processes and improve overall efficiency. In this article, we will explore some of the key advantages of using coffee sachet powder filling machines.

Coffee sachet powder filling machines are a crucial piece of equipment for businesses in the Food And Beverage industry. These machines offer a wide range of benefits that can help streamline production processes and improve overall efficiency. In this article, we will explore some of the key advantages of using coffee sachet powder filling machines.

One of the primary benefits of using coffee sachet powder filling machines is their ability to accurately measure and dispense the correct amount of product. This ensures consistency in the quality of the final product, as well as reducing waste and minimizing the risk of errors. By automating the filling process, these machines can help businesses save time and resources, allowing them to focus on other aspects of their operations.

In addition to improving accuracy, coffee sachet powder filling machines also offer increased speed and efficiency. These machines are capable of filling multiple sachets in a fraction of the time it would take to do so manually. This can help businesses meet high demand and increase production output, ultimately leading to higher profits and customer satisfaction.

Furthermore, coffee sachet powder filling machines are designed to be user-friendly and easy to operate. This makes them ideal for businesses of all sizes, from small startups to large-scale manufacturers. With minimal training required, employees can quickly learn how to use these machines effectively, reducing the risk of errors and ensuring a smooth production process.

Another key benefit of using coffee sachet powder filling machines is their versatility. These machines can be easily adjusted to accommodate different types of products and packaging sizes, making them suitable for a wide range of applications. Whether you are filling sachets with coffee, Tea, fruit juice powder, or any other powdered product, these machines can handle the task with ease.

Additionally, coffee sachet powder filling machines are designed to meet strict hygiene and Safety standards. With features such as Stainless Steel construction and easy-to-clean surfaces, these machines help ensure that products are filled in a clean and sanitary Environment. This is essential for businesses in the food and beverage industry, where product quality and safety are top priorities.

Overall, coffee sachet powder filling machines offer a host of benefits that can help businesses improve efficiency, accuracy, and productivity. By investing in these machines, businesses can streamline their production processes, reduce waste, and ultimately increase their bottom line. Whether you are a small startup or a large-scale manufacturer, coffee sachet powder filling machines are a valuable asset that can help take your business to the next level.

How to Choose the Right 20 kg Grain Packaging Machine

When it comes to Packaging Machines, choosing the right one for your specific needs is crucial. Whether you are in the food industry, pharmaceutical industry, or any other industry that requires packaging, having the right equipment can make a significant difference in your production process. One type of packaging machine that is commonly used in various industries is the 20 kg grain packaging machine.

These machines are designed to efficiently fill and pack grains, powders, and other similar products into bags or sachets. They are essential for businesses that deal with bulk quantities of these products and need a reliable and efficient way to package them. However, with so many options available in the market, it can be challenging to choose the right 20 kg grain packaging machine for your specific needs.

One of the first things to consider when choosing a 20 kg grain packaging machine is the type of product you will be packaging. Different machines are designed to handle different types of products, so it is essential to choose one that is suitable for the specific product you will be packaging. For example, if you are packaging fine powders, you will need a machine that can handle the delicate nature of these products without causing them to clump or clog the machine.

Another important factor to consider is the speed and efficiency of the machine. Depending on the volume of products you need to package, you may require a machine that can fill and pack bags quickly and accurately. Look for a machine that offers high-speed capabilities and can handle large quantities of product without compromising on accuracy.

In addition to speed and efficiency, it is also essential to consider the overall quality and durability of the machine. Investing in a high-quality 20 kg grain packaging machine will ensure that it can withstand the rigors of daily use and provide reliable performance for years to come. Look for machines made from durable materials and equipped with high-quality components to ensure longevity and reliability.

When choosing a 20 kg grain packaging machine, it is also crucial to consider the level of automation and customization options available. Some machines offer fully automated operation, while others may require more manual intervention. Depending on your specific needs and production requirements, you may prefer a machine that offers a high level of automation to streamline your packaging process.

Finally, consider the overall cost of the machine, including maintenance and operating costs. While it may be tempting to opt for a cheaper machine upfront, investing in a high-quality machine that offers reliable performance and longevity can save you money in the long run. Consider the total cost of ownership, including maintenance and operating costs, when making your decision.

In conclusion, choosing the right 20 kg grain packaging machine is essential for businesses that need to efficiently fill and pack grains, powders, and other similar products. Consider factors such as the type of product you will be packaging, speed and efficiency, quality and durability, automation and customization options, and overall cost when making your decision. By carefully evaluating these factors, you can choose a machine that meets your specific needs and provides reliable performance for years to come.