Table of Contents

Exploring the Advantages of A53 Sch10 Anti-Corrosion Galvanized Steel Pipes in China Factory

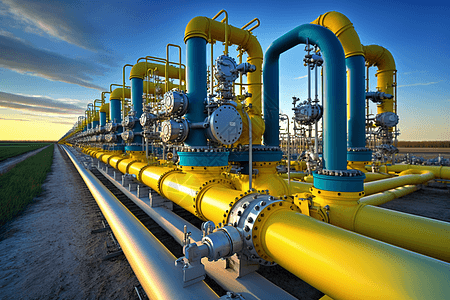

China has emerged as a global leader in the production of galvanized steel pipes, particularly A53 Sch10 Anti-Corrosion Galvanized Steel Pipes. These pipes, manufactured in China factories, offer a multitude of advantages that make them highly sought after in various industries worldwide. From their superior corrosion resistance to their seamless and welded construction, A53 Sch10 Anti-Corrosion Galvanized Steel Pipes stand out as a reliable solution for diverse applications.

One of the primary advantages of A53 Sch10 Anti-Corrosion Galvanized Steel Pipes lies in their exceptional resistance to corrosion. Galvanization involves coating steel with a layer of Zinc, which acts as a protective barrier against corrosive elements such as moisture and Chemicals. This anti-corrosion property makes these pipes ideal for use in environments prone to rust and degradation, ensuring longevity and durability.

Moreover, A53 Sch10 Galvanized Steel Pipes are available in both seamless and welded configurations, providing flexibility to suit different project requirements. Seamless pipes are manufactured without any seams or joints, offering uniformity in strength and structure. On the other hand, welded pipes are constructed by welding together individual sections, ensuring robustness and reliability in demanding applications.

The hot-dip galvanizing process further enhances the performance of these steel pipes. By immersing the steel in molten zinc, a metallurgical bond is formed between the zinc coating and the steel substrate, resulting in a tightly bonded layer that resists corrosion and abrasion. This ensures that A53 Sch10 Galvanized Steel Pipes maintain their integrity even in harsh operating conditions.

In addition to their superior corrosion resistance and construction, A53 Sch10 Galvanized Steel Pipes are known for their high strength-to-weight ratio. This makes them lightweight yet strong, facilitating ease of transportation, handling, and installation. Whether used in structural applications or fluid conveyance systems, these pipes offer reliable performance without compromising on structural integrity.

Furthermore, the versatility of A53 Sch10 Galvanized Steel Pipes makes them suitable for a wide range of applications across various industries. From plumbing and construction to automotive and agricultural sectors, these pipes find use in diverse applications where corrosion resistance and durability are paramount.

The seamless and welded options cater to different project specifications, providing engineers and contractors with the flexibility to choose the most suitable option for their needs. Whether it’s for underground pipelines, structural supports, or Industrial Machinery, A53 Sch10 Galvanized Steel Pipes offer a reliable solution that meets stringent performance requirements.

China’s manufacturing expertise and technological advancements have contributed significantly to the production of high-quality A53 Sch10 Anti-Corrosion Galvanized Steel Pipes. With state-of-the-art facilities and stringent quality control measures, Chinese factories ensure that these pipes meet international standards and specifications, making them a preferred choice for customers worldwide.

In conclusion, A53 Sch10 Anti-Corrosion Galvanized Steel Pipes manufactured in China factories offer a host of advantages that make them indispensable in various industries. Their superior corrosion resistance, seamless and welded construction, high strength-to-weight ratio, and versatility make them a reliable solution for diverse applications. As the demand for durable and reliable piping solutions continues to rise, A53 Sch10 Galvanized Steel Pipes stand out as a testament to China’s prowess in manufacturing top-quality steel products.

Understanding the Differences Between Seamless and Welded Hot-DIP Galvanized Steel Pipes: Dx51d+Z, Dx52D+Z, Dx53D+Z, Dx54D+Z, Dx56D+Z

Understanding the Differences Between Seamless and Welded Hot-DIP Galvanized Steel Pipes: Dx51d+Z, Dx52D+Z, Dx53D+Z, Dx54D+Z, Dx56D+Z

Hot-dip galvanized steel pipes are crucial components in various industrial applications, offering durability and corrosion resistance. When it comes to selecting the right type of galvanized steel pipe, one must consider factors like manufacturing process, material composition, and specific requirements of the application. Two primary categories of hot-dip galvanized steel pipes are seamless and welded, each offering distinct advantages and applications.

Seamless hot-dip galvanized steel pipes are manufactured through a continuous extrusion process, resulting in a seamless cylindrical shape without any welded joints. This manufacturing method ensures uniformity in the pipe’s structure and enhances its strength. In contrast, welded hot-dip galvanized steel pipes are fabricated by welding together pre-cut sections of steel, forming a longitudinal seam along the length of the pipe.

One significant difference between seamless and welded hot-dip galvanized steel pipes lies in their manufacturing process. Seamless pipes are produced from a solid cylindrical steel billet, which is heated and pushed or pulled over a mandrel to form the desired shape. On the other hand, welded pipes are created by joining steel plates or coils through welding, followed by hot-dip galvanization to provide corrosion protection.

Seamless hot-dip galvanized steel pipes exhibit superior mechanical properties compared to welded pipes due to their homogeneous structure and absence of welded seams. This makes seamless pipes suitable for high-pressure applications and environments with extreme temperatures. Welded pipes, while offering sufficient strength for many applications, may have slightly reduced mechanical properties near the weld area.

Another aspect to consider is the material composition of hot-dip galvanized steel pipes, denoted by designations such as Dx51d+Z, Dx52D+Z, Dx53D+Z, Dx54D+Z, and Dx56D+Z. These designations indicate the steel grade and zinc coating weight, which influence the pipe’s corrosion resistance and overall performance. Dx51d+Z, for example, denotes a hot-dip galvanized steel with a zinc coating of 51 grams per square meter, suitable for general applications.

The choice between different material grades depends on factors like environmental conditions, exposure to corrosive substances, and structural requirements. For instance, applications in harsh environments may necessitate higher-grade materials with thicker zinc coatings to ensure long-term durability and corrosion resistance.

In addition to material composition, the selection between seamless and welded hot-dip galvanized steel pipes depends on the specific requirements of the project. Seamless pipes are preferred for critical applications where strength, reliability, and uniformity are paramount. Welded pipes, on the other hand, offer cost advantages and are suitable for less demanding applications where moderate strength and corrosion resistance suffice.

In conclusion, understanding the differences between seamless and welded hot-dip galvanized steel pipes is essential for selecting the most appropriate option for a given application. While seamless pipes offer superior mechanical properties and uniformity, welded pipes provide cost-effective solutions for various industrial needs. The choice between different material grades further enhances the versatility of hot-dip galvanized steel pipes, allowing for customization based on specific project requirements. By considering factors like manufacturing process, material composition, and application demands, engineers and project managers can make informed decisions to ensure optimal performance and longevity of galvanized steel pipe installations.