Table of Contents

Bus Engine Maintenance Tips

Bus Engines are the heart of any bus, providing the power needed to transport passengers from one place to another. As such, it is crucial to properly maintain and care for the engine to ensure its longevity and optimal performance. In this article, we will discuss some important bus engine maintenance tips to help keep your bus running smoothly.

One of the most important aspects of bus engine maintenance is regular oil changes. Oil is essential for lubricating the engine’s moving parts and preventing wear and tear. It is recommended to change the oil every 5,000 to 7,000 miles, or as recommended by the manufacturer. Be sure to use the correct type of oil for your bus engine to ensure proper lubrication.

In addition to regular oil changes, it is also important to check and replace the Air Filter as needed. The air filter helps prevent dirt and debris from entering the engine, which can cause damage over time. A clogged air filter can reduce engine performance and fuel efficiency, so be sure to inspect and replace it regularly.

In addition to regular oil changes, it is also important to check and replace the Air Filter as needed. The air filter helps prevent dirt and debris from entering the engine, which can cause damage over time. A clogged air filter can reduce engine performance and fuel efficiency, so be sure to inspect and replace it regularly.

Another important aspect of bus engine maintenance is checking the coolant Levels and ensuring that the Cooling System is functioning properly. The cooling system helps regulate the engine’s temperature and prevent overheating. Be sure to check the coolant levels regularly and top off as needed. If you notice any leaks or overheating issues, be sure to have the cooling system inspected by a professional.

Regularly inspecting the belts and hoses in the engine compartment is also important for proper maintenance. Belts and hoses can wear out over time and should be replaced if they show signs of cracking, fraying, or other damage. A broken belt or hose can cause serious damage to the engine, so be sure to inspect them regularly and replace as needed.

In addition to these maintenance tasks, it is also important to keep the engine compartment clean and free of debris. Dirt and grime can build up in the engine compartment and cause damage over time. Be sure to regularly clean the engine compartment and remove any debris to prevent issues with the engine.

Finally, it is important to have regular inspections and maintenance performed by a qualified mechanic. A professional mechanic can identify any potential issues with the engine and address them before they become major problems. Regular maintenance can help prevent costly repairs and keep your bus running smoothly for years to come.

In conclusion, proper bus engine maintenance is essential for keeping your bus running smoothly and efficiently. By following these tips and staying on top of regular maintenance tasks, you can help ensure the longevity and optimal performance of your bus engine. Remember to schedule regular oil changes, check and replace the air filter, inspect the cooling system, check belts and hoses, keep the engine compartment clean, and have regular inspections performed by a qualified mechanic. By taking care of your bus engine, you can enjoy reliable transportation for years to come.

Upgrading Your Bus Car Chassis: What You Need to Know

When it comes to upgrading your bus car chassis, there are a few key components to consider. One of the most important parts of your bus chassis is the engine. The engine is the heart of your vehicle, providing the power needed to get you from point A to point B. When upgrading your bus chassis, it’s important to choose an engine that is reliable, efficient, and powerful enough to meet your needs.

There are a variety of bus engines available on the market, each with its own set of features and benefits. Some popular options include diesel engines, which are known for their durability and fuel efficiency, as well as gasoline engines, which are typically more affordable and easier to maintain. When choosing an engine for your bus chassis, it’s important to consider factors such as horsepower, torque, and fuel efficiency to ensure that you’re getting the best possible performance.

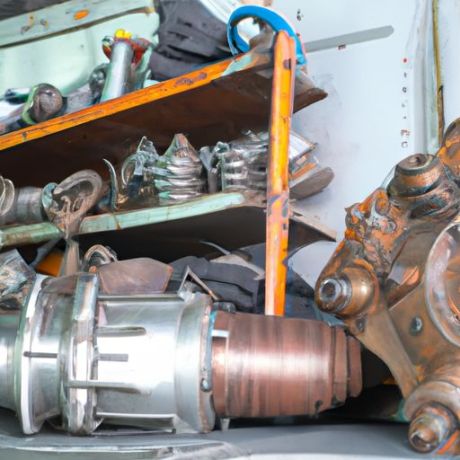

In addition to the engine, another important component of your bus chassis is the spare parts or Accessories. Spare parts are essential for keeping your bus running smoothly and efficiently, as they allow you to quickly replace worn or damaged components. Common spare parts for bus chassis include Brake Pads, Filters, belts, and hoses. It’s important to keep a stock of spare parts on hand to ensure that you can quickly address any issues that may arise while on the road.

When upgrading your bus chassis, it’s also important to consider the overall design and construction of the chassis itself. The chassis is the framework that supports the engine, transmission, and other components of your bus. A well-designed chassis can improve the overall performance and handling of your vehicle, while also providing a comfortable and safe ride for passengers.

There are a variety of bus chassis options available on the market, ranging from mini City Buses to large coach buses. Some popular bus chassis manufacturers include Kinglong, Higer, and Yutong, each of which offers a range of chassis options to suit different needs and budgets. When choosing a bus chassis, it’s important to consider factors such as size, weight capacity, and overall design to ensure that you’re getting the best possible fit for your vehicle.

In conclusion, upgrading your bus car chassis is an important decision that can have a significant impact on the performance and reliability of your vehicle. By choosing the right engine, spare parts, and chassis design, you can ensure that your bus is running at its best and providing a safe and comfortable ride for passengers. Whether you’re looking to upgrade an existing bus chassis or build a new vehicle from scratch, it’s important to carefully consider all of the options available to you to ensure that you’re getting the best possible results.