Table of Contents

Benefits of Using Biodegradable Vest Plastic Bags

In recent years, there has been a growing concern over the environmental impact of plastic bags. These single-use items are often discarded after just one use, leading to a significant amount of waste that ends up in landfills or polluting our oceans. As a result, many consumers and businesses are looking for more sustainable alternatives, such as biodegradable vest plastic bags.

Biodegradable vest plastic bags are made from materials that can break Down naturally in the Environment, reducing the amount of waste that ends up in landfills. These bags are designed to decompose over time, leaving behind no harmful residues or byproducts. This makes them a much more environmentally friendly option compared to traditional plastic bags.

One of the key benefits of using biodegradable vest plastic bags is their reduced impact on the environment. Unlike traditional plastic bags, which can take hundreds of years to decompose, biodegradable bags break down much more quickly. This means that they are less likely to contribute to pollution and can help to reduce the amount of waste that ends up in our landfills and oceans.

Another advantage of biodegradable vest plastic bags is that they are made from renewable resources. Many traditional plastic bags are made from non-renewable fossil fuels, which are a finite resource. In contrast, biodegradable bags are often made from plant-based materials such as Corn or potato Starch, which can be grown and harvested sustainably. This makes them a more sustainable option for businesses and consumers looking to reduce their environmental impact.

In addition to their environmental benefits, biodegradable vest plastic bags are also a practical choice for businesses. These bags are just as durable and versatile as traditional plastic bags, making them suitable for a wide range of applications. Whether you are a retailer looking for a convenient way to package products or a consumer in need of a reliable shopping bag, biodegradable vest plastic bags are a great option.

Furthermore, the use of biodegradable vest plastic bags can help businesses to enhance their brand image and appeal to environmentally conscious consumers. By demonstrating a commitment to sustainability and reducing their environmental impact, businesses can attract customers who are looking for more eco-friendly options. This can help to differentiate a business from its competitors and build loyalty among environmentally conscious consumers.

Overall, the benefits of using biodegradable vest plastic bags are clear. From their reduced environmental impact to their practicality and versatility, these bags offer a sustainable alternative to traditional plastic bags. By making the switch to biodegradable bags, businesses and consumers can help to reduce waste, conserve resources, and protect the environment for future generations.

How Automatic Cutting, Sealing, and Packing Machines Can Improve Efficiency in Packaging Operations

In today’s fast-paced world, efficiency is key in every aspect of business operations. This is especially true in the packaging industry, where the demand for quick and reliable packaging solutions is constantly on the rise. Automatic cutting, sealing, and packing machines have become essential tools for companies looking to streamline their packaging processes and improve overall efficiency.

One of the main advantages of using automatic cutting, sealing, and packing machines is the significant time savings they offer. These machines are designed to perform multiple tasks simultaneously, such as cutting, sealing, and packing, which can greatly reduce the amount of time it takes to package products. This not only increases productivity but also allows companies to meet tight deadlines and fulfill orders more quickly.

In addition to saving time, automatic machines also help improve the quality and consistency of packaging. Manual packaging processes are prone to human error, which can result in inconsistencies in the size, shape, and seal of the packaging. Automatic machines, on the other hand, are programmed to perform tasks with precision and accuracy, ensuring that each package is uniform and meets the desired specifications. This not only enhances the overall appearance of the product but also helps maintain its freshness and integrity during transportation and storage.

Furthermore, automatic cutting, sealing, and packing machines are versatile and can be customized to accommodate a wide range of packaging needs. Whether you are packaging food products, pharmaceuticals, or consumer goods, these machines can be adjusted to handle different types of materials, sizes, and shapes. This flexibility allows companies to adapt to changing market demands and expand their product offerings without having to invest in multiple machines.

Another key benefit of using automatic machines is the reduction in labor costs. By automating the packaging process, companies can significantly reduce the need for manual labor, which can be both costly and time-consuming. This not only helps companies save money but also allows them to reallocate resources to other areas of the business, such as marketing, research, and development.

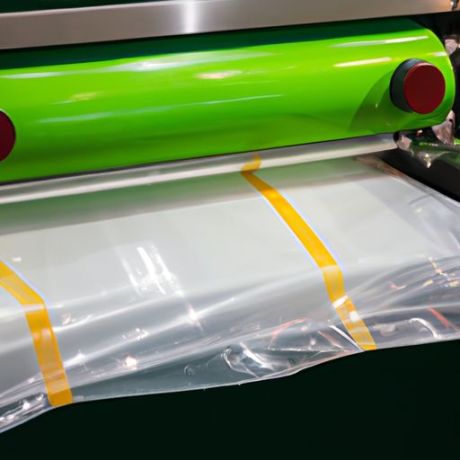

Moreover, automatic cutting, sealing, and packing machines are environmentally friendly, as they can help reduce waste and promote sustainability. Many of these machines are designed to use biodegradable materials, such as compostable Films and bags, which can help minimize the environmental impact of packaging operations. Additionally, these machines are equipped with advanced technology that allows for precise cutting and sealing, which can further reduce the amount of material wasted during the packaging process.

Moreover, automatic cutting, sealing, and packing machines are environmentally friendly, as they can help reduce waste and promote sustainability. Many of these machines are designed to use biodegradable materials, such as compostable Films and bags, which can help minimize the environmental impact of packaging operations. Additionally, these machines are equipped with advanced technology that allows for precise cutting and sealing, which can further reduce the amount of material wasted during the packaging process.

In conclusion, automatic cutting, sealing, and packing machines are invaluable tools for companies looking to improve efficiency in their packaging operations. These machines offer a wide range of benefits, including time savings, improved quality and consistency, versatility, reduced labor costs, and environmental sustainability. By investing in automatic machines, companies can streamline their packaging processes, increase productivity, and stay ahead of the competition in today’s fast-paced market.