Table of Contents

Advantages of Using API 5L Tube for Tubing and Casing Applications

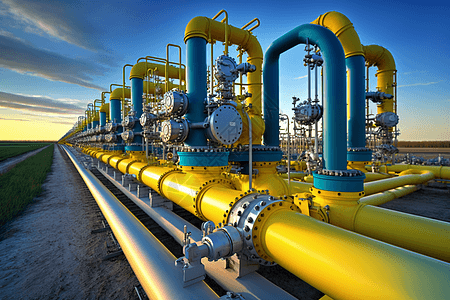

API 5L tube is a type of steel pipe that is commonly used in tubing and casing applications in the oil and gas industry. This high-quality pipe is manufactured according to the American Petroleum Institute (API) standards, which ensure its durability, strength, and reliability in demanding environments. There are several advantages to using API 5L tube for tubing and casing applications, making it a popular choice among industry professionals.

One of the main advantages of API 5L tube is its high strength and durability. This type of pipe is made from high-quality steel that has been specifically designed to withstand the harsh conditions of oil and gas drilling operations. API 5L tube is able to withstand high pressure, extreme temperatures, and corrosive substances, making it a reliable choice for tubing and casing applications.

In addition to its strength and durability, API 5L tube is also known for its excellent resistance to corrosion. The steel used in API 5L tube is specially treated to prevent rust and corrosion, ensuring that the pipe remains in good condition even in corrosive environments. This corrosion resistance helps to extend the lifespan of the pipe, reducing the need for frequent replacements and maintenance.

Another advantage of using API 5L tube for tubing and casing applications is its versatility. This type of pipe is available in a wide range of sizes and thicknesses, making it suitable for a variety of applications in the oil and gas industry. Whether you need a small diameter pipe for a shallow well or a large diameter pipe for a deep drilling operation, API 5L tube can be customized to meet your specific requirements.

Furthermore, API 5L tube is easy to install and maintain, saving time and money on installation and maintenance costs. The pipe is designed to be lightweight and easy to handle, making it quick and simple to install in the field. Additionally, the corrosion-resistant properties of API 5L tube help to reduce the need for frequent maintenance, saving both time and money over the lifespan of the pipe.

Overall, API 5L tube offers a number of advantages for tubing and casing applications in the oil and gas industry. Its high strength, durability, corrosion resistance, versatility, and ease of installation make it a reliable and cost-effective choice for a wide range of drilling operations. By choosing API 5L tube for your tubing and casing needs, you can ensure that your operations run smoothly and efficiently, with minimal downtime and maintenance requirements.

How to Ensure Compliance with API 5L Standards for Tube Manufacturing

API 5L is a set of standards that govern the manufacturing and testing of Steel Pipes used in the oil and gas industry. These standards are developed and maintained by the American Petroleum Institute (API) to ensure the quality and Safety of pipes used in the transportation of oil and gas. API 5L tubes are widely used in various applications, including tubing and casing for oil and gas wells.

To ensure compliance with API 5L standards for tube manufacturing, it is essential for manufacturers to follow the guidelines set forth by the API. This includes using the appropriate materials, manufacturing processes, and testing procedures to meet the requirements of API 5L.

One of the key requirements of API 5L standards is the use of high-quality materials in the manufacturing of tubes. The materials used must meet specific chemical composition and mechanical properties to ensure the strength and durability of the tubes. Manufacturers must carefully select and test the materials to ensure they meet the requirements of API 5L standards.

In addition to using the right materials, manufacturers must also follow specific manufacturing processes to produce tubes that meet API 5L standards. This includes processes such as hot rolling, cold drawing, and heat treatment to achieve the desired properties in the tubes. Manufacturers must also ensure that the tubes are produced with the correct dimensions and tolerances to meet the requirements of API 5L.

Testing is another critical aspect of ensuring compliance with API 5L standards for tube manufacturing. Manufacturers must conduct various tests on the tubes to verify their quality and performance. These tests may include chemical analysis, mechanical testing, non-destructive testing, and hydrostatic testing to ensure the tubes meet the requirements of API 5L.

To ensure compliance with API 5L standards, manufacturers must also maintain proper documentation of the manufacturing process and test results. This documentation is essential for verifying that the tubes meet the requirements of API 5L and for providing traceability in case of any issues or failures.

Overall, ensuring compliance with API 5L standards for tube manufacturing requires a comprehensive approach that includes using the right materials, following the correct manufacturing processes, conducting thorough testing, and maintaining proper documentation. By adhering to these guidelines, manufacturers can produce high-quality tubes that meet the requirements of API 5L and ensure the safety and reliability of oil and gas operations.

In conclusion, API 5L standards play a crucial role in ensuring the quality and safety of tubes used in the oil and gas industry. Manufacturers must follow the guidelines set forth by the API to ensure compliance with these standards. By using the right materials, following the correct manufacturing processes, conducting thorough testing, and maintaining proper documentation, manufacturers can produce tubes that meet the requirements of API 5L and provide reliable performance in oil and gas applications.