Table of Contents

Benefits of Using API-5CT Oil Seamless Steel Casing Pipe in Oil and Gas Industry

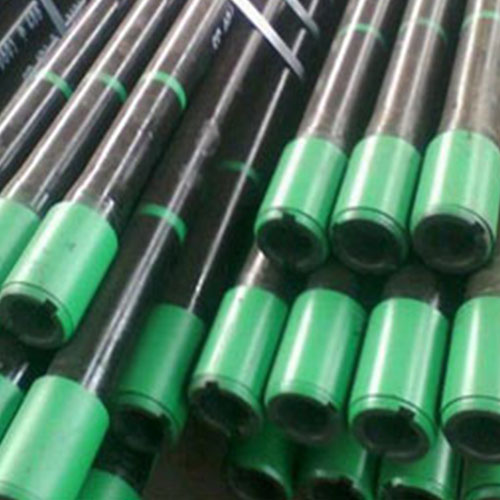

The oil and gas industry relies heavily on the use of high-quality materials to ensure the safe and efficient extraction of resources. One such material that plays a crucial role in this industry is API-5CT oil seamless steel casing pipe. This type of pipe is specifically designed to withstand the harsh conditions of oil and gas wells, making it an essential component for drilling operations.

One of the key benefits of using API-5CT oil seamless steel casing pipe is its durability. This type of pipe is made from high-quality steel that is designed to withstand high pressure and extreme temperatures. This means that it can be used in a variety of challenging environments without compromising its structural integrity. In addition, the seamless design of this pipe reduces the risk of leaks and failures, ensuring a reliable and long-lasting solution for oil and gas drilling operations.

Another advantage of API-5CT oil seamless steel casing pipe is its resistance to corrosion. The harsh Chemicals and corrosive substances present in oil and gas wells can cause traditional pipes to deteriorate over time. However, the high-quality steel used in API-5CT casing pipe is specifically formulated to resist corrosion, ensuring that it remains intact and functional for an extended period of time. This not only reduces the need for frequent maintenance and repairs but also helps to prevent costly downtime and production delays.

Furthermore, API-5CT oil seamless steel casing pipe is designed to provide a tight seal, preventing the escape of oil, gas, and other fluids from the well. This helps to maintain pressure within the wellbore, ensuring efficient extraction and production processes. Additionally, the seamless design of this pipe reduces the risk of leaks and failures, further enhancing its reliability and performance in oil and gas drilling operations.

In addition to its durability, corrosion resistance, and tight seal capabilities, API-5CT oil seamless steel casing pipe is also highly versatile. It can be easily customized to meet the specific requirements of different drilling operations, making it a flexible and adaptable solution for a wide range of applications. Whether drilling in shallow or deep wells, onshore or offshore, API-5CT casing pipe can be tailored to suit the unique needs of each project, ensuring optimal performance and efficiency.

Overall, API-5CT oil seamless steel casing pipe offers a range of benefits that make it an ideal choice for the oil and gas industry. Its durability, corrosion resistance, tight seal capabilities, and versatility make it a reliable and cost-effective solution for drilling operations. By choosing API-5CT casing pipe, companies can ensure the Safety, efficiency, and success of their oil and gas projects, ultimately leading to increased productivity and profitability in the long run.

How to Ensure Quality and Compliance When Using API-5CT Oil Seamless Steel Casing Pipe

API-5CT oil seamless steel casing pipe is a critical component in the oil and gas industry, used to protect and support the wellbore during drilling and production operations. It is essential that these pipes meet stringent quality and compliance standards to ensure the safety and efficiency of oil and gas operations. In this article, we will discuss how to ensure quality and compliance when using API-5CT oil seamless steel casing pipe.

One of the most important factors to consider when using API-5CT oil seamless steel casing pipe is the material quality. These pipes are typically made from carbon or Alloy Steel, and it is crucial to ensure that the material meets the specifications outlined in the API-5CT standard. This includes requirements for chemical composition, mechanical properties, and dimensional tolerances. To verify the material quality, it is essential to work with reputable suppliers who can provide material test reports and certifications.

In addition to material quality, it is also important to consider the manufacturing process of API-5CT oil seamless steel casing pipe. The pipes should be manufactured using high-quality equipment and processes to ensure consistency and reliability. This includes processes such as hot rolling, heat treatment, and finishing operations. It is recommended to work with manufacturers who have a proven track record of producing high-quality API-5CT oil seamless steel casing pipe.

Another key aspect to consider is the inspection and testing of API-5CT oil seamless steel casing pipe. These pipes should undergo rigorous testing to ensure they meet the requirements of the API-5CT standard. This includes non-destructive testing methods such as ultrasonic testing, magnetic particle testing, and visual inspection. It is important to work with suppliers who have the necessary testing capabilities and can provide documentation to verify the quality of the pipes.

Furthermore, it is essential to consider compliance with regulatory requirements when using API-5CT oil seamless steel casing pipe. In many regions, there are specific regulations and standards that govern the use of oil and gas equipment, including casing pipes. It is important to ensure that the pipes meet these requirements to avoid any potential safety or environmental issues. Working with suppliers who are knowledgeable about these regulations and can provide the necessary documentation is crucial.

Overall, ensuring quality and compliance when using API-5CT oil seamless steel casing pipe is essential for the success of oil and gas operations. By focusing on material quality, manufacturing processes, inspection and testing, and regulatory compliance, companies can minimize risks and ensure the reliability of their operations. It is important to work with reputable suppliers who can provide high-quality pipes and support throughout the procurement process. By following these guidelines, companies can ensure the safety and efficiency of their oil and gas operations.