Table of Contents

Key Features and Specifications of API 5CT J55 K55 Seamless Casing Tubing

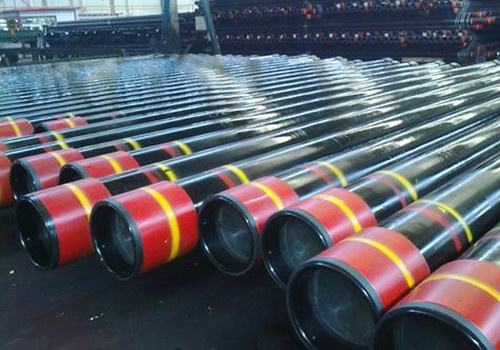

API 5CT J55 K55 Seamless Casing Tubing is a critical component in the oil and gas industry, serving as a conduit for the extraction and transportation of hydrocarbons from reservoirs deep beneath the Earth’s surface. Understanding its key features and specifications is essential for professionals in this sector to ensure optimal performance and Safety in their operations.

These seamless casing tubing products adhere to the standards set by the American Petroleum Institute (API), specifically API 5CT, which establishes criteria for the manufacturing, testing, and certification of casing and tubing used in the exploration and production of oil and gas. The designation “J55” and “K55” refers to the material grade of the casing tubing, each with its own unique properties and characteristics.

One of the standout features of API 5CT J55 K55 Seamless Casing Tubing is its seamless construction. Unlike welded tubing, which is formed by joining separate pieces together, seamless tubing is manufactured from a single solid billet of steel through a process that involves piercing a hollow cylindrical ingot and then elongating it to the desired length and diameter. This seamless design offers several advantages, including enhanced structural integrity, better resistance to corrosion and fatigue, and smoother internal surfaces that facilitate the flow of fluids.

In addition to their seamless construction, API 5CT J55 K55 Seamless Casing Tubing also meets stringent dimensional and mechanical specifications. These include precise outer diameter (OD) and wall thickness measurements, as well as requirements for yield strength, tensile strength, and hardness. These specifications ensure that the casing tubing can withstand the harsh operating conditions encountered in oil and gas wells, including high pressures, temperatures, and corrosive environments.

Furthermore, API 5CT J55 K55 Seamless Casing Tubing is available in various lengths and connection types to accommodate different well designs and drilling techniques. Common connection types include API threads, which are standardized screw threads that allow for easy installation and removal of the tubing, as well as premium connections, which offer enhanced sealing and mechanical properties for challenging applications such as deepwater drilling and hydraulic fracturing.

Another important consideration when selecting API 5CT J55 K55 Seamless Casing Tubing is its compliance with international quality and safety standards. In addition to API specifications, these products may also be subject to regulations imposed by other governing bodies, such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM). Compliance with these standards ensures that the casing tubing meets the highest industry standards for performance, reliability, and safety.

In conclusion, API 5CT J55 K55 Seamless Casing Tubing offers a reliable and efficient solution for the extraction and transportation of oil and gas in the most demanding environments. Its seamless construction, precise dimensions, and mechanical properties make it a preferred choice for oilfield operators and drilling contractors worldwide. By understanding its key features and specifications, professionals in the oil and gas industry can make informed decisions when selecting casing tubing for their operations, ensuring optimal performance and safety every step of the way.

Advantages and Applications of Seamless Pls2 Casing Tubing

API 5CT J55 K55 Seamless Casing Tubing Seamless Pls2: Advantages and Applications

API 5CT J55 K55 Seamless Casing Tubing Seamless Pls2 holds significant advantages in various industrial applications. Seamless Pls2 casing tubing, constructed according to stringent API standards, offers reliability, durability, and versatility in challenging environments. In this article, we explore the advantages and applications of Seamless Pls2 casing tubing, highlighting its importance across different sectors.

One of the primary advantages of Seamless Pls2 casing tubing is its seamless construction, which eliminates the presence of welds or joints along the length of the tubing. This seamless design enhances structural integrity, reducing the risk of leaks, fractures, or other defects that could compromise performance. By ensuring a continuous and uniform surface, Seamless Pls2 casing tubing enhances operational efficiency and minimizes maintenance requirements.

Additionally, Seamless Pls2 casing tubing is engineered to withstand high pressures and temperatures, making it suitable for demanding oil and gas exploration and production environments. Its robust composition enables it to withstand corrosive elements, abrasive substances, and extreme conditions encountered during drilling, completion, and production operations. This durability ensures prolonged service life and reduces downtime, contributing to overall cost-effectiveness.

Seamless Pls2 casing tubing finds extensive applications in the oil and gas industry, where it serves multiple functions throughout the wellbore lifecycle. During drilling operations, Seamless Pls2 casing tubing provides structural support, preventing the collapse of the wellbore and maintaining its integrity. It also facilitates the efficient extraction of hydrocarbons by allowing for the installation of production equipment such as Pumps, packers, and Valves.

Furthermore, Seamless Pls2 casing tubing plays a crucial role in well completion and stimulation activities. It serves as a conduit for hydraulic fracturing fluids, enabling the injection of proppants and Chemicals into the formation to enhance productivity. Additionally, Seamless Pls2 casing tubing facilitates the installation of downhole tools and instrumentation for reservoir evaluation and monitoring purposes.

Beyond the oil and gas industry, Seamless Pls2 casing tubing finds applications in various other sectors, including geothermal energy production, mining, and construction. In geothermal energy production, Seamless Pls2 casing tubing is utilized for the construction of geothermal wells, where it provides thermal insulation and withstands high-pressure steam and fluid environments. In mining operations, Seamless Pls2 casing tubing is employed for dewatering, ventilation, and ore extraction purposes, thanks to its durability and corrosion resistance.

In the construction sector, Seamless Pls2 casing tubing is utilized for deep foundation projects such as piling and caisson construction, where it provides structural support and prevents soil collapse during excavation. Its seamless design ensures optimal performance and reliability in demanding underground environments.

In conclusion, API 5CT J55 K55 Seamless Casing Tubing Seamless Pls2 offers a host of advantages and applications across various industries. Its seamless construction, durability, and versatility make it an indispensable component in critical operations such as oil and gas exploration, geothermal energy production, mining, and construction. As industries continue to evolve and demand high-performance materials, Seamless Pls2 casing tubing remains a preferred choice for meeting stringent requirements and ensuring operational excellence.