目录

Factors Affecting the Cost of Filling, Capping, and Labeling Machines

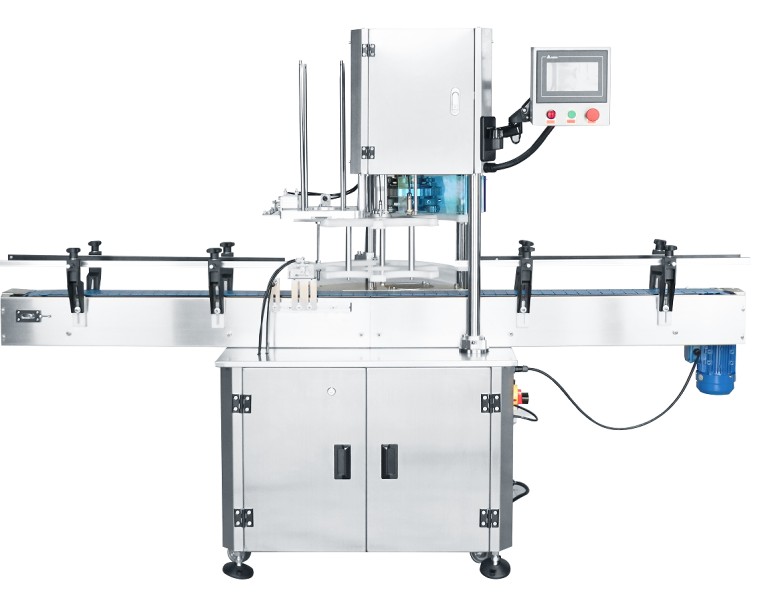

Filling, capping, and labeling machines are essential equipment for businesses in industries such as Food And Beverage, pharmaceuticals, cosmetics, and more. These machines automate the process of filling Containers, sealing them with caps, and labeling them with product information. The cost of these machines can vary significantly depending on various factors.

One of the primary factors that affect the cost of filling, capping, and labeling machines is the type of machine. There are different types of machines available, ranging from semi-automatic to fully automatic. Semi-automatic machines require more manual labor and are generally less expensive than fully automatic machines, which can operate without much human intervention. The complexity of the machine and the level of automation it offers will impact its cost.

Another factor that influences the cost of these machines is the production capacity. Machines with higher production capacities are typically more expensive than those with lower capacities. The size and speed of the machine will determine how many containers it can fill, cap, and label in a given amount of time. Businesses with higher production demands will need to invest in machines that can keep up with their output requirements, which may come at a higher cost.

The quality and durability of the machine also play a significant role in determining its cost. Machines made from high-quality materials and components are likely to be more expensive upfront but can offer better performance and longevity. Investing in a high-quality machine can result in fewer breakdowns and maintenance costs in the long run, making it a more cost-effective choice for businesses in the long term.

Additionally, the brand and reputation of the manufacturer can impact the cost of filling, capping, and labeling machines. Well-known and established manufacturers may charge higher prices for their machines due to their reputation for quality and reliability. While machines from lesser-known manufacturers may be more affordable, they may not offer the same level of performance or support as machines from reputable brands.

Customization options and additional features can also affect the cost of filling, capping, and labeling machines. Businesses that require specific features or modifications to meet their unique needs may need to pay extra for customization. Similarly, machines with advanced features such as automatic changeover, remote monitoring, or integration with other equipment may come at a higher price point.

In conclusion, the cost of filling, capping, and labeling machines can vary depending on a variety of factors. The type of machine, production capacity, quality, brand, customization options, and additional features all play a role in determining the price of these machines. Businesses should carefully consider their production requirements, budget, and long-term goals when choosing a filling, capping, and labeling machine to ensure they make a wise investment that meets their needs.

Comparing Different Brands and Models of Filling, Capping, and Labeling Machines

Filling, capping, and labeling machines are essential equipment for businesses in the packaging industry. These machines automate the process of filling containers, sealing them with caps, and labeling them with product information. Investing in these machines can significantly increase efficiency and productivity in a Production Line. However, one of the most critical factors to consider when purchasing these machines is the cost.

The cost of filling, capping, and labeling machines can vary significantly depending on the brand, model, and features. It is essential to compare different brands and models to find the best machine that fits your budget and production needs. Some factors that can affect the cost of these machines include the capacity, speed, and level of automation.

When comparing different brands and models of filling, capping, and labeling machines, it is essential to consider the capacity of the machine. The capacity refers to the amount of product that the machine can fill, cap, and label in a given time. Machines with higher capacities are generally more expensive than those with lower capacities. However, investing in a machine with a higher capacity can increase productivity and reduce production time in the long run.

Another factor to consider when comparing filling, capping, and labeling machines is the speed of the machine. The speed refers to how quickly the machine can fill, cap, and label containers. Machines with higher speeds are typically more expensive than those with lower speeds. If you have a high-volume production line, investing in a machine with a higher speed can help you meet production demands efficiently.

The level of automation is also an essential factor to consider when comparing filling, capping, and labeling machines. Fully automated machines can fill, cap, and label containers without the need for manual intervention, while semi-automated machines require some manual input. Fully automated machines are generally more expensive than semi-automated machines. However, investing in a fully automated machine can help reduce labor costs and increase efficiency in the production line.

When comparing different brands and models of filling, capping, and labeling machines, it is essential to consider the overall cost of ownership. The overall cost of ownership includes not only the initial purchase price of the machine but also maintenance, repair, and operating costs. Some brands and models may have lower initial purchase prices but higher maintenance and operating costs in the long run. It is essential to consider the total cost of ownership when comparing different machines to find the most cost-effective option for your business.

In conclusion, the cost of filling, capping, and labeling machines can vary significantly depending on the brand, model, and features. When comparing different brands and models, it is essential to consider factors such as capacity, speed, level of automation, and overall cost of ownership. Investing in the right machine can help increase efficiency and productivity in your production line.

Tips for Budgeting and Financing the Purchase of Filling, Capping, and Labeling Machines

Filling, capping, and labeling machines are essential equipment for businesses in industries such as food and beverage, pharmaceuticals, cosmetics, and more. These machines automate the process of filling containers, sealing them with caps, and labeling them with product information. Investing in these machines can significantly increase efficiency and productivity in your production process. However, one of the key considerations when purchasing filling, capping, and labeling machines is the cost.

The cost of filling, capping, and labeling machines can vary widely depending on factors such as the type of machine, its capacity, and its features. Generally, Filling Machines are the most expensive, followed by Capping Machines, and labeling machines are usually the least expensive. The cost of these machines can range from a few thousand dollars to several hundred thousand dollars, depending on the size and complexity of the machine.

When budgeting for filling, capping, and labeling machines, it’s important to consider not just the upfront cost of the machines, but also the long-term costs associated with maintenance, repairs, and upgrades. It’s also important to factor in the cost of training your staff to operate the machines effectively. Additionally, you may need to budget for other expenses such as installation, shipping, and taxes.

One way to finance the purchase of filling, capping, and labeling machines is through equipment financing. Equipment financing allows you to spread out the cost of the machines over time, making it more manageable for your business. There are several options for equipment financing, including loans, leases, and equipment financing agreements. Each option has its own advantages and disadvantages, so it’s important to carefully consider which option is best for your business.

Another option for financing the purchase of filling, capping, and labeling machines is to seek funding from investors or lenders. This can be a good option if you need a large amount of capital upfront to purchase the machines. However, it’s important to carefully consider the terms of any funding agreement to ensure that it’s a good fit for your business.

When budgeting for filling, capping, and labeling machines, it’s also important to consider the return on investment (ROI) that these machines can provide. By automating the filling, capping, and labeling process, you can significantly increase efficiency and productivity in your production process. This can Lead to cost savings, increased output, and improved product quality, all of which can contribute to a positive ROI for your business.

In conclusion, filling, capping, and labeling machines are essential equipment for businesses in industries such as food and beverage, pharmaceuticals, cosmetics, and more. The cost of these machines can vary widely depending on factors such as the type of machine, its capacity, and its features. When budgeting for filling, capping, and labeling machines, it’s important to consider not just the upfront cost of the machines, but also the long-term costs associated with maintenance, repairs, and upgrades. Financing options such as equipment financing and funding from investors or lenders can help make the purchase of these machines more manageable for your business. Ultimately, investing in filling, capping, and labeling machines can lead to increased efficiency, productivity, and profitability for your business.