目录

Benefits of Using API Oil Well Casing Tube/Pipe in Drilling Operations

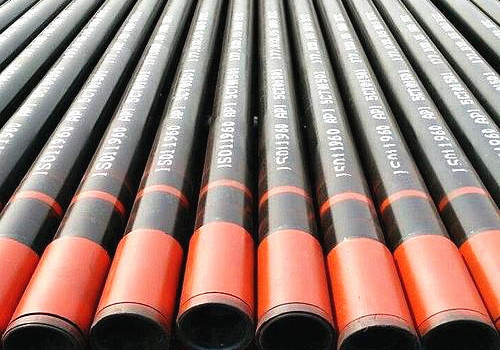

API oil well casing tube/pipe is a crucial component in drilling operations for oil and gas wells. This type of casing is made from hot rolled steel, which provides the necessary strength and durability to withstand the harsh conditions of drilling deep into the earth. The API (American Petroleum Institute) sets the standards for oil well casing, ensuring that it meets the requirements for Safety and performance in the oil and gas industry.

One of the key benefits of using API oil well casing tube/pipe is its ability to protect the wellbore from collapsing. When drilling into the earth, the pressure from the surrounding rock formations can cause the wellbore to collapse if it is not properly supported. API casing provides a strong and stable structure that prevents this from happening, ensuring the integrity of the wellbore throughout the drilling process.

In addition to providing structural support, API oil well casing tube/pipe also helps to prevent contamination of the surrounding groundwater. As drilling operations penetrate through various layers of rock and soil, there is a risk of fluids from the wellbore seeping into the groundwater and causing pollution. The casing acts as a barrier, preventing any fluids from escaping and protecting the Environment from potential harm.

Another benefit of using API oil well casing tube/pipe is its compatibility with wireline hardened drill rods. Wireline drilling is a common technique used in oil and gas exploration, where a series of drill rods are connected together to reach greater depths. The casing pipe provides a stable foundation for the drill rods, allowing for smooth and efficient drilling operations.

API oil well casing tube/pipe is available in a variety of sizes and grades, including NQ, HQ, PQ, BQ, NW, HW, and PW. These different sizes and grades allow for flexibility in designing drilling operations to meet specific requirements. Whether drilling a shallow well or a deep well, there is a casing pipe available to suit the needs of the project.

Furthermore, API oil well casing tube/pipe is designed to withstand high temperatures and pressures, making it ideal for drilling operations in challenging environments. The hot rolled steel construction ensures that the casing can withstand the extreme conditions encountered during drilling, providing a reliable and durable solution for oil and gas exploration.

Overall, the benefits of using API oil well casing tube/pipe in drilling operations are clear. From providing structural support and preventing contamination to enabling compatibility with wireline drill rods and withstanding high temperatures and pressures, API casing pipe is an essential component in the oil and gas industry. By adhering to the standards set by the American Petroleum Institute, companies can ensure the safety and efficiency of their drilling operations, ultimately leading to successful exploration and production of oil and gas resources.

The Importance of Proper Maintenance for Water Well Drilling Equipment

Water well drilling equipment is essential for accessing clean and safe water for various purposes, such as drinking, irrigation, and industrial use. Proper maintenance of this equipment is crucial to ensure its longevity and efficiency. One key component of water well drilling equipment is the casing tube/pipe, which plays a vital role in the drilling process.

https://www.youtube.com/watch?v=kcGBRz7l738

API oil well water well drilling hot rolled steel casing tube/pipe is commonly used in water well drilling operations due to its durability and strength. It is available in various sizes, including NQ, HQ, PQ, BQ, NW, HW, and PW, to accommodate different drilling requirements. The casing tube/pipe serves as a protective barrier for the wellbore, preventing collapse and maintaining the integrity of the well.

Wireline hardened drill rod is another essential component of water well drilling equipment. It is used to advance the drilling process by rotating and driving the drill bit into the ground. The hardened drill rod is designed to withstand the high torque and pressure exerted during drilling operations, ensuring smooth and efficient drilling.

Proper maintenance of casing pipe and drill rod is essential to ensure the safety and efficiency of water well drilling operations. Regular inspection and cleaning of the equipment can help prevent corrosion, wear, and damage, which can compromise the integrity of the wellbore. In addition, proper lubrication of the drill rod can reduce friction and wear, prolonging its lifespan and ensuring smooth drilling operations.

Regular maintenance of water well drilling equipment also includes monitoring the condition of the casing pipe and drill rod during drilling operations. Any signs of wear, corrosion, or damage should be addressed promptly to prevent further deterioration and potential safety hazards. In addition, proper storage of the equipment when not in use can help prevent damage and extend its lifespan.

In conclusion, proper maintenance of water well drilling equipment, including casing pipe and drill rod, is essential to ensure the safety and efficiency of drilling operations. Regular inspection, cleaning, and lubrication of the equipment can help prevent corrosion, wear, and damage, prolonging its lifespan and ensuring smooth drilling operations. By following proper maintenance practices, water well drilling operators can maximize the performance and longevity of their equipment, ultimately ensuring the availability of clean and safe water for various purposes.