目录

成本比较

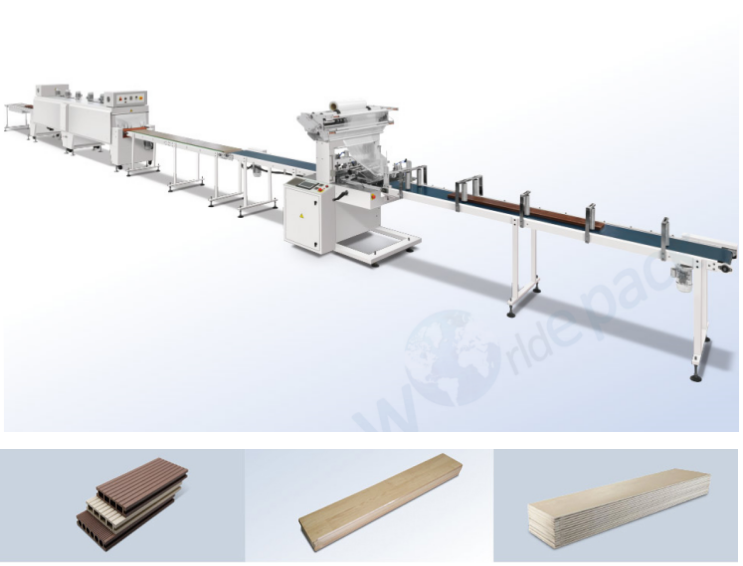

当谈到包装产品时,企业有多种选择可供选择。最常见的方法之一是使用包装机安全地包装物品以进行运输或存储。两种流行的包装机类型是热收缩包装机和常规包装机。虽然两者都具有相同的包装产品用途,但企业在决定投资哪种类型的机器时应考虑两者之间的一些关键区别。

企业在热收缩包装机和热收缩包装机之间进行选择时考虑的主要因素之一普通的包装机是成本。与普通包装机相比,热收缩包装机的前期成本往往更高。这是因为热收缩包装机使用热源来收缩产品周围的塑料薄膜,这需要额外的技术和设备。另一方面,常规包装机只需将产品包裹在塑料薄膜中,无需加热,这对于预算有限的企业来说是一个更具成本效益的选择。

除了初始成本外,企业还应该考虑持续的成本与每种类型的包装机相关的成本。热收缩包装机需要使用收缩膜,这可能比普通包装机中使用的塑料膜更昂贵。这意味着使用热收缩包装机的企业随着时间的推移可能会产生更高的材料成本。另一方面,常规包装机通常使用较便宜的塑料薄膜,对于希望最大限度地减少包装费用的企业来说,它们是更具成本效益的选择。

企业的另一个成本考虑因素是与每种类型相关的维护和维修成本。缠绕机。与普通包装机相比,热收缩包装机的设计更加复杂,这使得它们更容易出现机械问题和故障。这意味着使用热收缩包装机的企业可能需要在维护和维修方面投入更多资金,以保持机器平稳运行。相比之下,普通包装机设计更简单,不太可能出现机械问题,从而为企业带来较低的维护和维修成本。

总的来说,在比较热收缩包装机和普通包装机的成本时,企业应该考虑不仅包括机器的前期成本,还包括持续的材料成本和维护费用。虽然热收缩包装机的初始成本可能较高,但优先考虑效率和产品展示的企业可能会发现投资值得。另一方面,希望最大限度地减少包装费用的企业可能会选择常规包装机作为更具成本效益的选择。

总而言之,在热收缩包装机和常规包装机之间进行选择时,成本是需要考虑的重要因素机器。企业应权衡前期成本、持续材料成本和维护费用,以确定哪种类型的包装机最适合其预算和包装需求。通过仔细评估这些成本考虑因素,企业可以做出明智的决定,决定是投资热收缩包装机还是常规包装机进行包装操作。

效率与速度

当谈到包装产品时,企业有多种选择可供选择。最常见的方法之一是使用包装机安全地包装物品以进行运输或存储。两种流行的包装机类型是热收缩包装机和常规包装机。虽然两者都具有相同的包装产品用途,但两者在效率和速度方面存在一些关键区别。

热收缩包装机设计用于将产品包装在一层塑料薄膜中,该塑料薄膜在受热时会收缩。这会在产品周围形成紧密、安全的密封,保护其在运输过程中免受损坏。热收缩包装机的主要优点之一是其效率。这些机器可以快速、轻松地包装产品,非常适合需要在短时间内包装大量物品的企业。

相比之下,常规包装机使用多种材料,如拉伸膜、纸张,或用胶带包裹产品。虽然这些机器也很高效,但它们可能无法提供与热收缩包装机相同水平的保护。此外,常规包装机可能需要更多的体力操作,这会减慢包装过程。

热收缩包装机和普通包装机之间的另一个主要区别是速度。热收缩包装机通常比普通包装机更快,因为它们可以在几秒钟内包装产品。这对于有大批量包装需求或紧迫期限的企业尤其有利。另一方面,常规包装机可能需要更长的时间来包装产品,具体取决于所使用的材料类型和复杂性包装过程。虽然这些机器仍然高效,但在包装大量物品时,它们可能不如热收缩包装机快。

总而言之,在效率和速度方面,热收缩包装机具有明显的优势超过普通包装机。这些机器可以快速、安全地包装产品,使其成为具有大批量包装需求的企业的理想选择。虽然常规包装机仍然有效,但它们可能无法提供与热收缩包装机相同水平的效率或速度。

Ultimately, the choice between heat shrink Wrapping Machines and regular wrapping machines will depend on the specific needs of a business. For businesses that require fast and efficient packaging solutions, heat shrink wrapping machines may be the best option. However, for businesses that prioritize cost-effectiveness or flexibility in packaging materials, regular wrapping machines may be a better choice. Regardless of the type of wrapping machine chosen, businesses can rest assured that their products will be securely packaged and protected during transit.

Durability and Longevity

When it comes to packaging products, businesses have a variety of options to choose from. One of the most common methods is using wrapping machines to securely package items for shipping or storage. Two popular types of wrapping machines are heat shrink wrapping machines and regular wrapping machines. While both serve the same purpose of packaging products, there are some key distinctions between the two that businesses should consider when deciding which type of machine to invest in.

One of the main distinctions between heat shrink wrapping machines and regular wrapping machines is their durability and longevity. Heat shrink wrapping machines are known for their ability to provide a tight and secure seal around products, making them ideal for protecting items during transit. The heat shrink film used in these machines shrinks tightly around the product when heat is applied, creating a strong barrier that helps prevent damage or tampering.

Regular wrapping machines, on the other hand, typically use stretch film to wrap products. While stretch film can provide some level of protection, it is not as secure as heat shrink film. Regular wrapping machines may be more prone to tears or punctures, which can compromise the integrity of the packaging and leave products vulnerable to damage.

In terms of durability, heat shrink wrapping machines are often considered to be more robust and long-lasting than regular wrapping machines. The heat shrink film used in these machines is designed to withstand rough handling and environmental conditions, making it a reliable choice for businesses that need to package products securely. Regular wrapping machines may require more frequent maintenance and replacement of parts, which can add to the overall cost of using these machines.

Additionally, heat shrink wrapping machines are often more versatile than regular wrapping machines when it comes to the types of products that can be packaged. Heat shrink film can conform to the shape of almost any product, making it suitable for a wide range of items. Regular wrapping machines may have limitations in terms of the size and shape of products that can be wrapped, which can be a drawback for businesses with diverse packaging needs.

Overall, when considering the durability and longevity of wrapping machines, businesses should weigh the benefits of heat shrink wrapping machines against regular wrapping machines. While heat shrink wrapping machines may have a higher upfront cost, their ability to provide a secure and tight seal around products can help businesses save money in the long run by reducing the risk of damaged or lost items. Additionally, the versatility and durability of heat shrink wrapping machines make them a reliable choice for businesses that need to package a variety of products securely.

In conclusion, the main distinctions between heat shrink wrapping machines and regular wrapping machines in terms of durability and longevity make it clear that businesses should carefully consider their packaging needs before investing in a wrapping machine. While regular wrapping machines may be suitable for some applications, businesses that require a higher level of protection and Security for their products may find that heat shrink wrapping machines are the better choice. By weighing the benefits and drawbacks of each type of machine, businesses can make an informed decision that will help them package products securely and efficiently.