Table of Contents

Benefits of Using Warm Mix Technology Agents in Asphalt Production

Warm mix technology agents have been gaining popularity in the asphalt industry, especially among Asian wholesalers. These agents are used to lower the production temperature of asphalt mixtures, resulting in numerous benefits for both the Environment and the quality of the final product.

One of the main advantages of using warm mix technology agents is the reduction in energy consumption during the production process. By lowering the temperature at which the asphalt mixture is produced, less energy is required to heat the materials, leading to lower fuel consumption and reduced greenhouse gas emissions. This not only helps to lower production costs but also contributes to a more sustainable and environmentally friendly asphalt production process.

In addition to the environmental benefits, warm mix technology agents also offer improvements in the workability and compaction of the asphalt mixture. The lower production temperature allows for better coating and adhesion of the aggregate particles, resulting in a more uniform and durable pavement. This leads to a longer service life of the asphalt pavement, reducing the need for frequent maintenance and repairs.

| Nr. | Products |

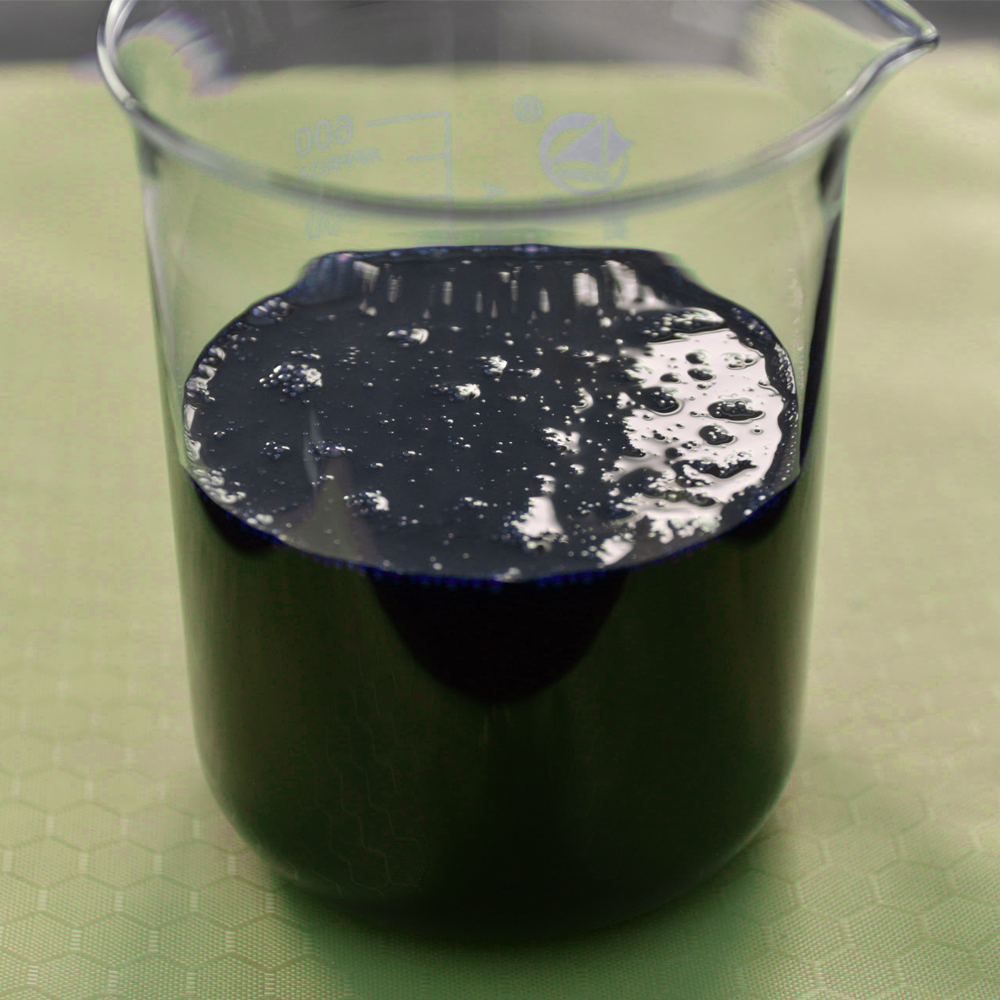

| 1 | Warm Mixing asphalt blend additives |

Furthermore, warm mix technology agents can help to reduce the aging of the asphalt binder, resulting in a longer-lasting pavement. The lower production temperature minimizes the oxidative aging of the binder, preserving its properties and ensuring better performance over time. This can Lead to cost savings for road agencies and contractors, as they will not have to replace or repair the pavement as frequently.

Another benefit of using warm mix technology agents is the improved work environment for workers on the job site. The lower production temperature reduces the emission of harmful fumes and odors, creating a safer and more comfortable working environment. This can lead to increased productivity and morale among workers, as well as a reduced risk of health issues related to exposure to asphalt fumes.

Overall, warm mix technology agents offer a wide range of benefits for Asian wholesalers and asphalt producers. From reducing energy consumption and greenhouse gas emissions to improving the quality and durability of the asphalt pavement, these agents are a valuable tool for enhancing the sustainability and performance of asphalt production.

In conclusion, warm mix technology agents are a game-changer in the asphalt industry, offering numerous benefits for Asian wholesalers and producers. By lowering the production temperature of asphalt mixtures, these agents help to reduce energy consumption, improve the quality of the pavement, and create a safer work environment for workers. With the growing emphasis on sustainability and environmental responsibility, warm mix technology agents are becoming an essential component of modern asphalt production processes.

How Asian Wholesalers Can Benefit from Warm Mix Technology Agents

Warm mix technology agents are revolutionizing the way asphalt mixtures are produced and laid, offering numerous benefits over traditional hot mix methods. Asian wholesalers, in particular, stand to gain significantly from incorporating warm mix technology agents into their operations. In this article, we will explore how Asian wholesalers can benefit from the use of warm mix technology agents in their asphalt production processes.

One of the key advantages of warm mix technology agents is their ability to lower the production and laying temperatures of asphalt mixtures. This not only reduces energy consumption and greenhouse gas emissions but also extends the paving season in colder climates. Asian wholesalers can take advantage of this by being able to produce and lay asphalt mixtures in a wider range of weather conditions, ultimately increasing their operational efficiency and profitability.

Furthermore, warm mix technology agents have been shown to improve the workability and compaction of asphalt mixtures, resulting in a smoother and more durable pavement surface. This can lead to reduced maintenance costs and longer pavement life, which are particularly important considerations for Asian wholesalers operating in regions with heavy traffic and harsh weather conditions.

In addition, warm mix technology agents can help Asian wholesalers meet increasingly stringent environmental regulations by reducing emissions of volatile organic compounds (VOCs) and other harmful pollutants. By using warm mix technology agents, wholesalers can demonstrate their commitment to sustainability and environmental stewardship, which can enhance their reputation and competitiveness in the marketplace.

Another benefit of warm mix technology agents is their ability to reduce the aging of asphalt binders, resulting in improved long-term performance of pavement surfaces. This can translate into lower life cycle costs for Asian wholesalers, as they will need to invest less in maintenance and rehabilitation over the lifespan of the pavement.

Moreover, warm mix technology agents can enhance the overall quality and consistency of asphalt mixtures, leading to improved pavement performance and customer satisfaction. Asian wholesalers can differentiate themselves in the market by offering superior asphalt products that are more durable, sustainable, and cost-effective than those produced using traditional hot mix methods.

In conclusion, warm mix technology agents offer a wide range of benefits for Asian wholesalers looking to improve their asphalt production processes. By incorporating warm mix technology agents into their operations, wholesalers can reduce energy consumption, lower production and laying temperatures, improve workability and compaction, meet environmental regulations, enhance pavement performance, and increase customer satisfaction. Ultimately, the adoption of warm mix technology agents can help Asian wholesalers stay competitive in the rapidly evolving asphalt industry and position themselves as leaders in sustainability and innovation.