Table of Contents

Viscosity-Modifying Additives for Asphalt Pavements

Viscosity-modifying additives play a crucial role in enhancing the performance of asphalt pavements. These additives are designed to improve the flow properties of asphalt, making it easier to work with during construction and ensuring long-term durability of the pavement. In China, the use of viscosity asphalt additives has become increasingly popular due to their ability to enhance the quality of asphalt pavements.

One of the key advantages of viscosity-modifying additives is their ability to reduce the viscosity of asphalt at high temperatures. This allows for better workability of the asphalt during construction, making it easier to achieve a smooth and uniform pavement surface. In addition, these additives can also improve the resistance of asphalt to rutting and cracking, leading to a longer service life for the pavement.

China has been at the forefront of developing and implementing advanced viscosity-modifying additives for asphalt pavements. Superior assembly lines in China are equipped with state-of-the-art technology that allows for the precise dosing and mixing of additives with asphalt. This ensures that the additives are evenly distributed throughout the asphalt mixture, resulting in consistent performance of the pavement.

Furthermore, China’s superior assembly lines are capable of producing a wide range of viscosity-modifying additives to meet the specific requirements of different pavement projects. Whether it is a high-traffic highway or a residential street, these assembly lines can tailor the additives to enhance the performance of the asphalt pavement in any setting.

In addition to improving the flow properties of asphalt, viscosity-modifying additives can also enhance the overall durability of the pavement. By reducing the viscosity of asphalt at high temperatures, these additives can help prevent rutting and cracking, which are common issues that can compromise the structural integrity of the pavement. This results in a longer service life for the pavement, reducing the need for costly repairs and maintenance in the future.

China’s superior assembly lines are equipped with advanced quality control measures to ensure that the viscosity-modifying additives meet the highest standards of performance. Each batch of additives is carefully tested to ensure that it meets the specified requirements for viscosity reduction and durability enhancement. This commitment to quality ensures that the additives produced in China are of the highest quality and can deliver superior performance in asphalt pavements.

In conclusion, viscosity-modifying additives are essential for enhancing the performance of asphalt pavements. China’s superior assembly lines are leading the way in developing and producing advanced additives that can improve the flow properties and durability of asphalt. By investing in these additives, pavement contractors can ensure the long-term performance and durability of their asphalt pavements, leading to safer and more reliable roadways for drivers and pedestrians alike.

Enhancing Efficiency in China’s Superior Assembly Line Operations

In the realm of manufacturing, efficiency is key to success. This is especially true in China’s superior assembly line operations, where every second counts in the production process. One crucial aspect of enhancing efficiency in assembly line operations is the use of viscosity asphalt additives. These additives play a vital role in ensuring the smooth and seamless operation of assembly lines, particularly in the production of asphalt-based products.

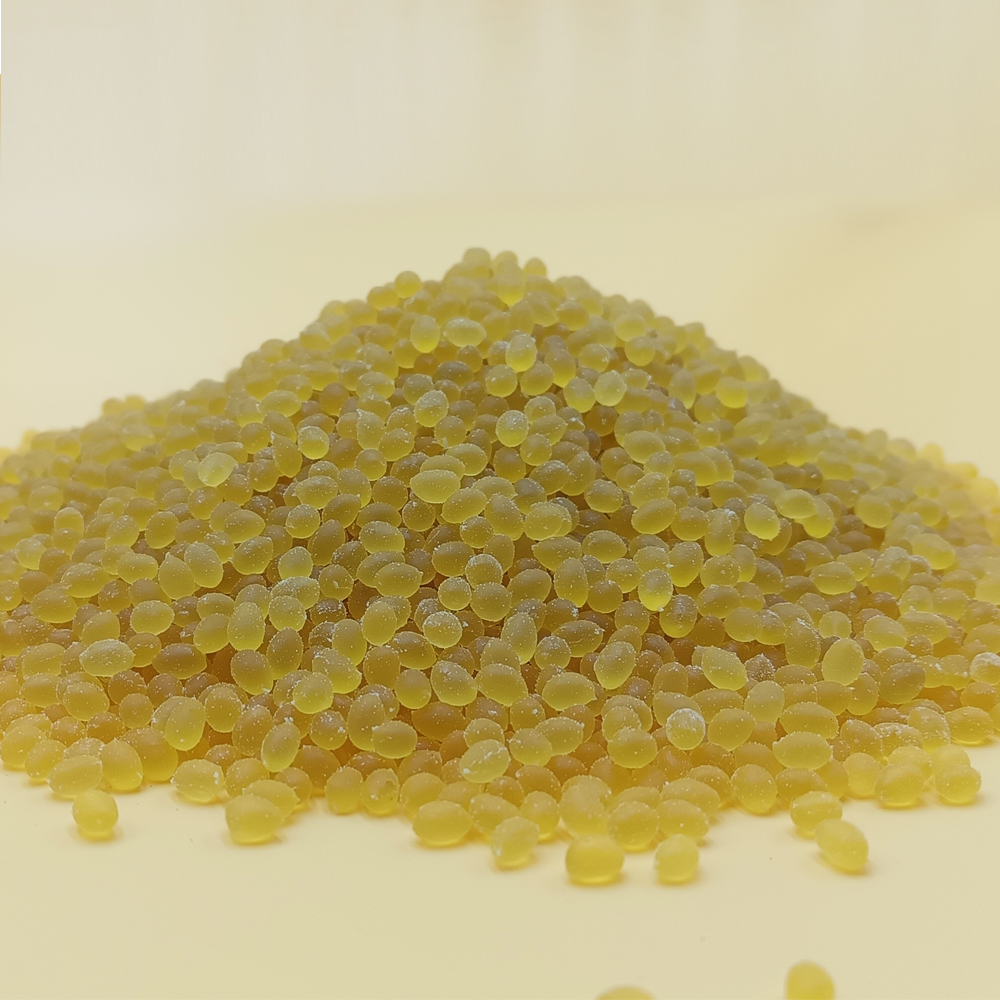

Viscosity asphalt additives are chemical compounds that are added to asphalt mixtures to modify their viscosity and improve their performance characteristics. These additives can help to enhance the flow properties of asphalt, making it easier to work with and ensuring a more consistent end product. In China’s superior assembly line operations, the use of viscosity asphalt additives has become increasingly common as manufacturers seek to streamline their production processes and improve overall efficiency.

| No. | Products |

| 1 | Thickener for Bitumen |

One of the key benefits of using viscosity asphalt additives in assembly line operations is their ability to reduce the overall viscosity of asphalt mixtures. This can help to improve the flow properties of the asphalt, making it easier to handle and work with during the production process. By reducing viscosity, manufacturers can also achieve a more consistent end product, with fewer defects and inconsistencies in the final asphalt product.

Another important benefit of viscosity asphalt additives is their ability to improve the overall performance characteristics of asphalt mixtures. By modifying the viscosity of the asphalt, these additives can help to enhance its durability, flexibility, and resistance to wear and tear. This can result in a longer-lasting and more reliable end product, which is crucial in assembly line operations where quality and consistency are paramount.

In China’s superior assembly line operations, the use of viscosity asphalt additives has become an essential tool for manufacturers looking to enhance efficiency and improve the overall quality of their products. By incorporating these additives into their production processes, manufacturers can achieve a more streamlined and efficient operation, with fewer delays and disruptions along the assembly line.

Furthermore, viscosity asphalt additives can also help to reduce production costs by improving the overall efficiency of the manufacturing process. By enhancing the flow properties of asphalt mixtures, these additives can help to reduce waste and minimize the need for rework, resulting in cost savings for manufacturers. This can be particularly beneficial in China’s competitive manufacturing Environment, where cost efficiency is a key factor in maintaining a competitive edge.

Overall, viscosity asphalt additives play a crucial role in enhancing efficiency in China’s superior assembly line operations. By improving the flow properties and performance characteristics of asphalt mixtures, these additives can help manufacturers to achieve a more streamlined and efficient production process, with higher quality and more consistent end products. As China continues to Lead the way in manufacturing innovation, the use of viscosity asphalt additives will undoubtedly play a key role in driving efficiency and success in assembly line operations.