Table of Contents

Benefits of Using Polymer Fibers in Road Construction

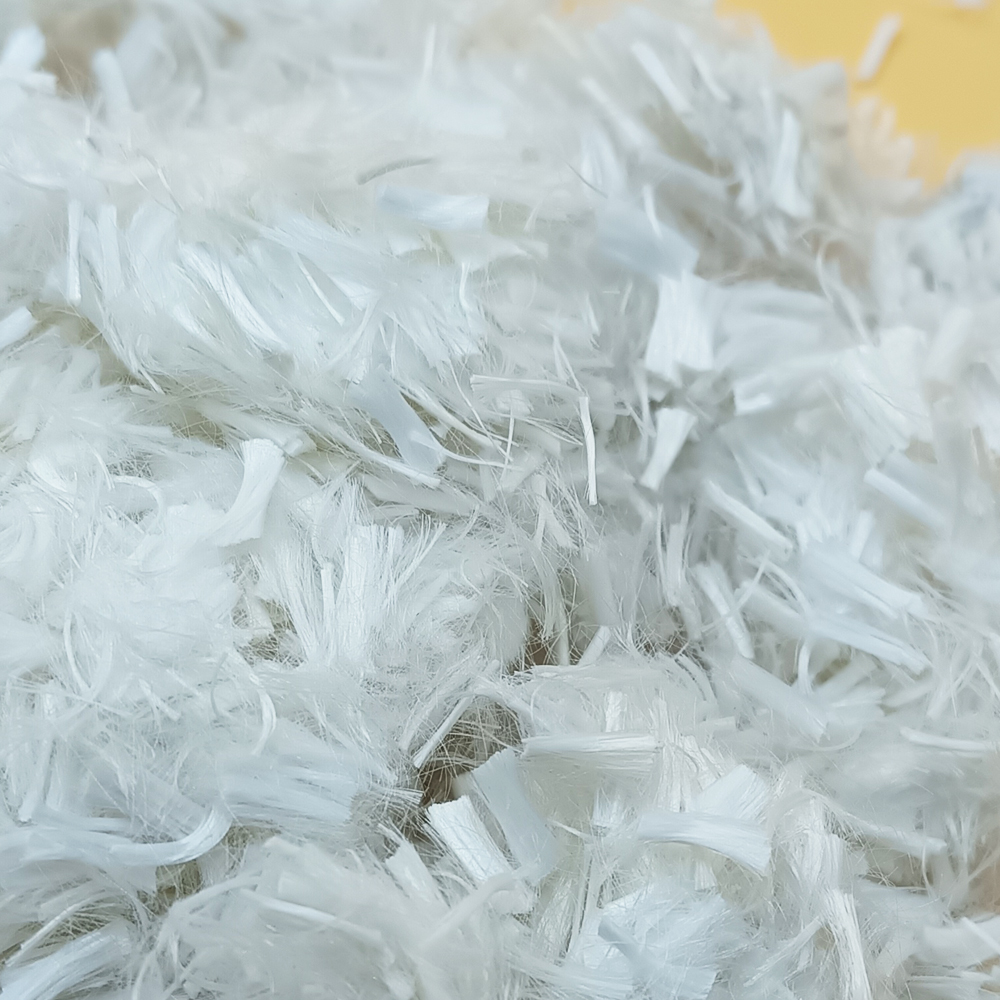

Polymer fibers have become increasingly popular in road construction due to their numerous benefits. These synthetic fibers, made from materials such as polyester, polypropylene, and nylon, offer a range of advantages that make them a preferred choice for enhancing the durability and longevity of roadways.

One of the key benefits of using polymer fibers in road construction is their ability to improve the overall strength of the pavement. When added to the asphalt mix, these fibers help to distribute the load more evenly across the surface, reducing the risk of cracking and rutting. This enhanced strength also allows the road to better withstand heavy traffic and harsh weather conditions, ultimately extending its lifespan.

In addition to improving strength, polymer fibers also enhance the flexibility of the pavement. By increasing the elasticity of the asphalt mix, these fibers help to prevent the formation of cracks and potholes, which can be costly to repair and disruptive to traffic flow. This flexibility is particularly important in regions that experience extreme temperature fluctuations, as it helps the road surface to expand and contract without sustaining damage.

Another advantage of using polymer fibers in road construction is their ability to reduce maintenance costs. By strengthening the pavement and preventing the formation of cracks, these fibers help to minimize the need for frequent repairs and resurfacing. This not only saves money in the long run but also reduces the inconvenience caused by road closures and detours.

| Nr. | Commodity Name |

| 1 | PET Fiber for bitumen |

Furthermore, polymer fibers can improve the Safety of roadways by enhancing skid resistance. The addition of these fibers to the asphalt mix creates a rougher surface texture, which helps to increase traction and reduce the risk of accidents, especially in wet or icy conditions. This improved skid resistance can make roads safer for drivers, cyclists, and pedestrians alike.

In addition to their functional benefits, polymer fibers are also environmentally friendly. These synthetic fibers are often made from recycled materials, reducing the demand for new resources and minimizing waste. By choosing to use polymer fibers in road construction, municipalities and transportation agencies can contribute to sustainability efforts and reduce their carbon footprint.

Overall, the use of polymer fibers in road construction offers a range of benefits that make them a valuable addition to any pavement project. From improving strength and flexibility to reducing maintenance costs and enhancing safety, these synthetic fibers provide a cost-effective and sustainable solution for enhancing the durability and longevity of roadways. As technology continues to advance, it is likely that polymer fibers will play an increasingly important role in the construction and maintenance of roads around the world.

Environmental Impact of Synthetic Fibers in Roadways

Polymer fibers have become increasingly popular in the construction of roadways due to their durability and longevity. These synthetic fibers are made from a variety of materials, including polyester, nylon, and polypropylene, and are used to reinforce asphalt and concrete in order to improve the overall strength and performance of the road surface. While polymer fibers offer many benefits in terms of road construction, there are also concerns about their environmental impact.

One of the main environmental concerns associated with the use of synthetic fibers in roadways is the potential for these materials to leach harmful Chemicals into the surrounding soil and water. As polymer fibers break Down over time, they can release toxic substances that may pose a threat to the Environment and human health. Additionally, the production of synthetic fibers requires the use of fossil fuels and other non-renewable resources, which can contribute to air and water pollution.

Despite these environmental concerns, there are also potential benefits to using polymer fibers in road construction. For example, the use of synthetic fibers can help to reduce the amount of asphalt and concrete needed for roadways, which in turn can lower the overall carbon footprint of road construction projects. Additionally, polymer fibers can help to extend the lifespan of road surfaces, reducing the need for frequent repairs and maintenance, which can also have a positive impact on the environment.

In order to mitigate the environmental impact of synthetic fibers in roadways, it is important for road construction companies to carefully consider the materials they use and to implement best practices for the disposal and Recycling of polymer fibers. This may include using recycled synthetic fibers whenever possible, as well as properly disposing of any waste materials in accordance with local regulations.

Furthermore, research is ongoing to develop more sustainable alternatives to traditional polymer fibers for road construction. For example, some companies are exploring the use of biodegradable fibers made from natural materials such as bamboo or Hemp, which could help to reduce the environmental impact of road construction projects. These natural fibers have the potential to break down more easily in the environment, reducing the risk of pollution and harm to ecosystems.

Overall, the use of synthetic fibers in roadways presents both benefits and challenges in terms of environmental impact. While these materials can help to improve the strength and durability of road surfaces, they also have the potential to leach harmful chemicals into the environment and contribute to pollution. By carefully considering the materials used in road construction and exploring more sustainable alternatives, it is possible to minimize the environmental impact of synthetic fibers in roadways and create more eco-friendly infrastructure for the future.