Table of Contents

Benefits of Using a Steel Wire Cutting Machine

Steel wire cutting machines are essential tools in various industries that require precise cutting of steel wires. These machines are designed to cut through steel wires effortlessly, providing a clean and accurate cut every time. One of the main advantages of using a steel wire cutting machine is its ability to cut through thick steel wires with ease. This makes it an ideal tool for industries that work with heavy-duty materials on a regular basis.

In addition to its cutting capabilities, a steel wire cutting machine also offers a high level of precision. This is crucial in industries where accuracy is paramount, such as in the manufacturing of automotive parts or aerospace components. With a steel wire cutting machine, operators can ensure that each cut is made to the exact specifications required, resulting in a finished product that meets the highest quality standards.

Another benefit of using a steel wire cutting machine is its efficiency. These machines are designed to work quickly and efficiently, allowing operators to cut through large quantities of steel wire in a short amount of time. This can help to increase productivity and reduce production costs, making it a cost-effective solution for businesses looking to streamline their operations.

Furthermore, steel wire cutting machines are also incredibly versatile. They can be used to cut through a wide range of steel wire sizes and types, making them suitable for a variety of applications. Whether you need to cut through thin steel wires or thick cables, a steel wire cutting machine can handle the job with ease.

One common concern that some people have about using steel wire cutting machines is whether Carbon Steel can rust. While it is true that carbon steel can rust when exposed to moisture and oxygen, the risk of rusting can be minimized by taking proper care of the machine. Regular maintenance and cleaning can help to prevent rust from forming on the machine, ensuring that it remains in optimal working condition for years to come.

Overall, the benefits of using a steel wire cutting machine far outweigh any potential drawbacks. From its cutting precision and efficiency to its versatility and durability, a steel wire cutting machine is a valuable tool for any industry that works with steel wires on a regular basis. By investing in a high-quality machine and taking proper care of it, businesses can enjoy the many advantages that come with using this essential piece of equipment.

Understanding the Strength of Model Wire Rope Under Its Own Weight

Steel wire cutting machines are essential tools in various industries that require precise cutting of steel wires. These machines are designed to cut through thick steel wires with ease, making them ideal for applications such as construction, manufacturing, and automotive industries. One important factor to consider when using a steel wire cutting machine is the strength of the wire rope under its own weight.

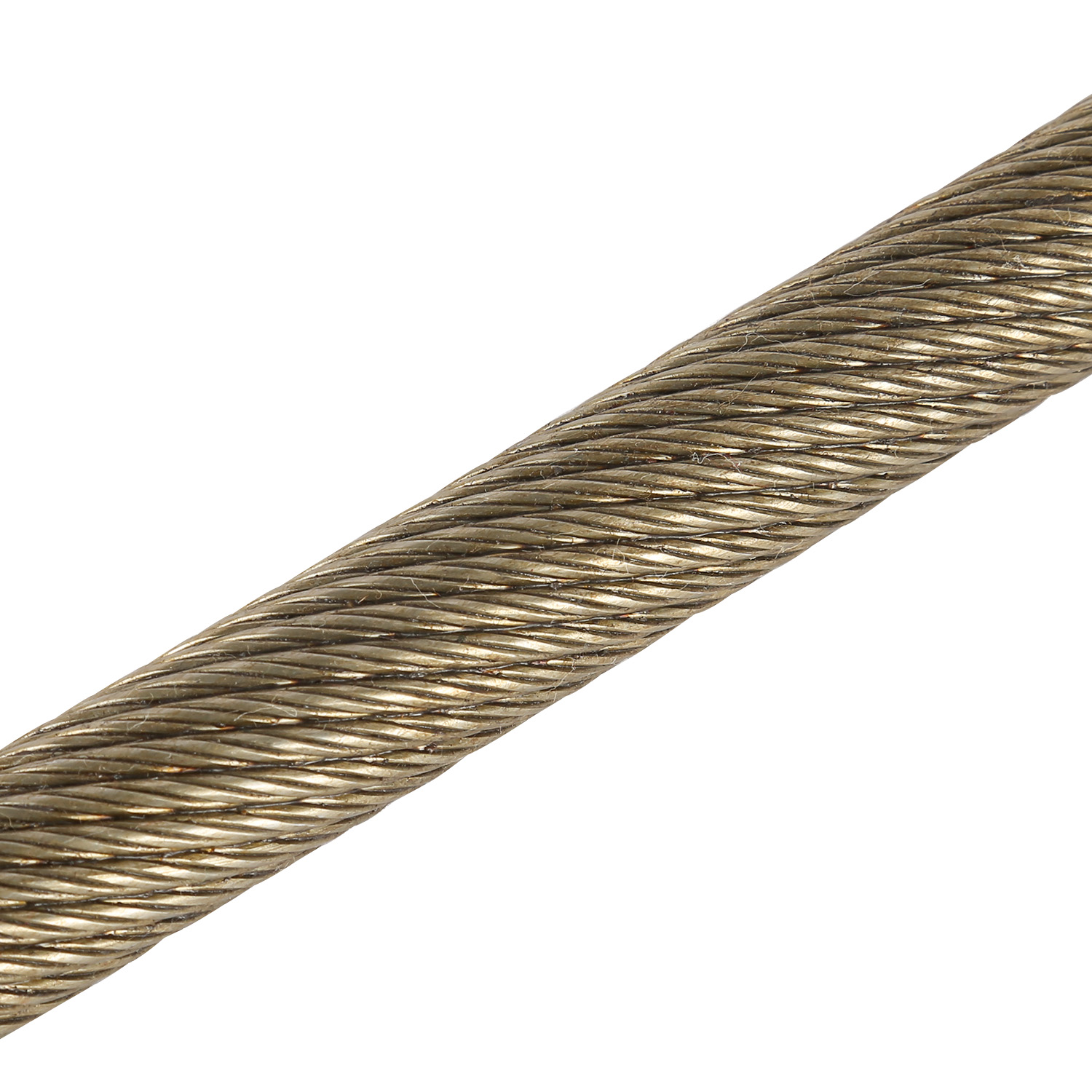

Model wire rope is a type of steel wire rope that is commonly used in various applications due to its high strength and durability. When a model wire rope is suspended under its own weight, it experiences a certain amount of stress and strain. Understanding the strength of model wire rope under its own weight is crucial for ensuring the Safety and efficiency of any application that involves the use of steel wire ropes.

The strength of model wire rope under its own weight is determined by various factors, including the material composition of the wire rope, the diameter of the wire rope, and the length of the wire rope. Carbon steel is a common material used in the manufacturing of model wire ropes due to its high strength and durability. However, one common concern with carbon steel is its susceptibility to rust.

Rust is a form of corrosion that occurs when Iron or steel is exposed to oxygen and moisture. Carbon steel is prone to rusting, especially when exposed to harsh environmental conditions such as saltwater or acidic substances. Rust can weaken the structure of the steel wire rope, reducing its strength and durability over time.

To prevent rusting and ensure the longevity of model wire ropes, it is important to properly maintain and protect them from environmental factors that can cause corrosion. Regular cleaning and lubrication of the wire ropes can help prevent rust formation and extend their lifespan. Additionally, storing the wire ropes in a dry and well-ventilated area can help reduce the risk of rusting.

When using a steel wire cutting machine to cut model wire ropes, it is important to consider the strength of the wire rope under its own weight to ensure safe and efficient cutting operations. The weight of the wire rope can exert a significant amount of stress on the cutting machine, so it is essential to use a machine that is capable of handling the load.

In conclusion, understanding the strength of model wire rope under its own weight is crucial for ensuring the safety and efficiency of any application that involves the use of steel wire ropes. By considering factors such as material composition, diameter, and length of the wire rope, as well as taking steps to prevent rust formation, users can maximize the lifespan and performance of model wire ropes. Proper maintenance and care of steel wire cutting machines are also essential for safe and efficient cutting operations.