Table of Contents

Benefits of Using Galvanized Carbon Steel Pipe in Construction Projects

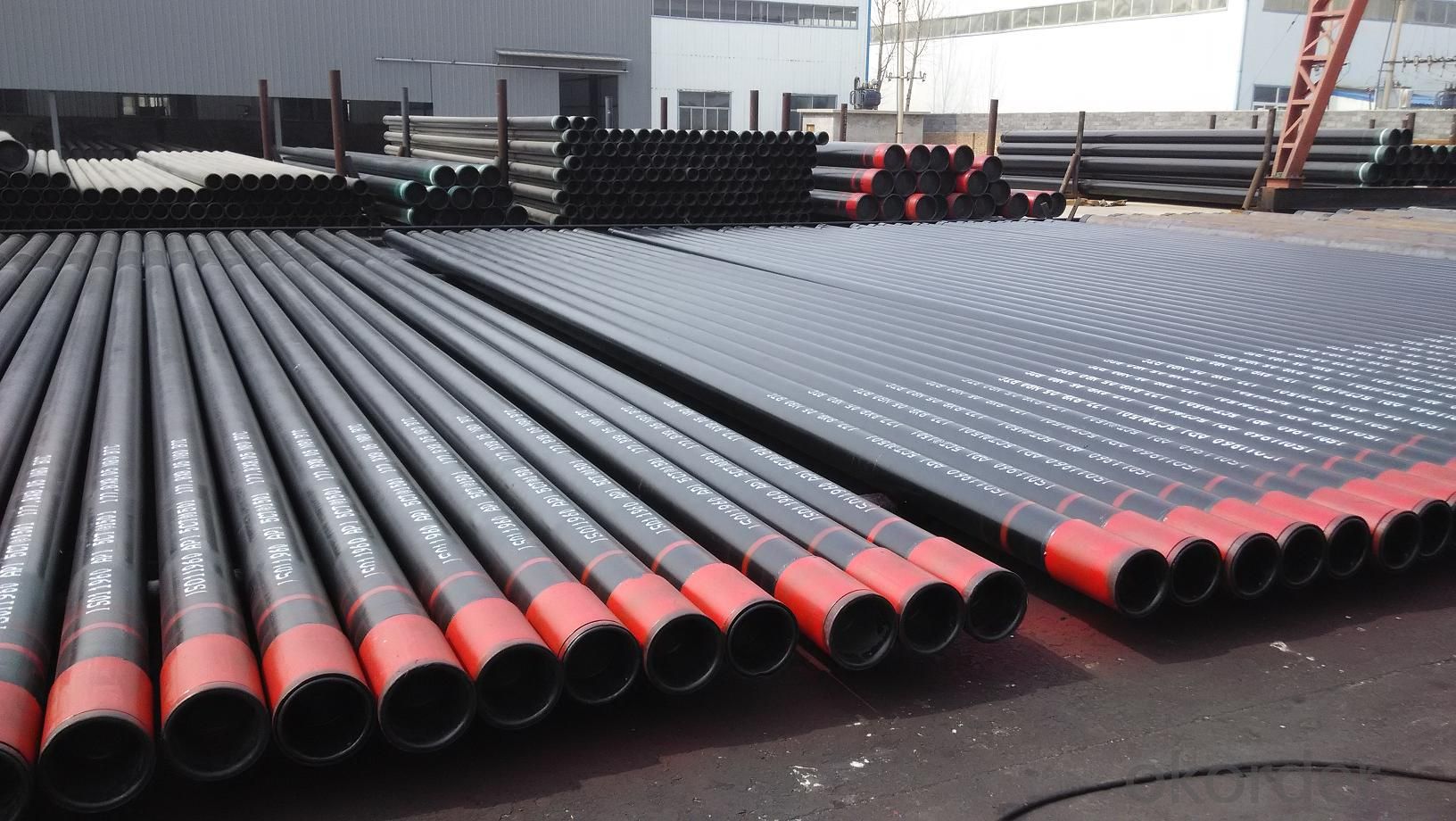

Steel Pipes are a crucial component in construction projects, providing structural support and carrying fluids or gases throughout a building. Galvanized carbon steel pipes, in particular, offer numerous benefits that make them a popular choice among builders and contractors.

One of the main advantages of using galvanized carbon steel pipes in construction is their durability. Galvanization involves coating the steel with a layer of Zinc, which helps protect the metal from corrosion and rust. This protective barrier extends the lifespan of the pipes, making them a cost-effective option for long-term projects.

In addition to their durability, galvanized carbon steel pipes are also highly resistant to damage from external elements such as water, Chemicals, and extreme temperatures. This makes them ideal for use in a variety of environments, including outdoor construction sites and industrial settings where the pipes may be exposed to harsh conditions.

Furthermore, galvanized carbon steel pipes are easy to install and require minimal maintenance. Their smooth surface allows for efficient fluid flow, reducing the risk of Clogs or blockages. This can help improve the overall efficiency of a construction project and save time and money on repairs and replacements in the long run.

Another benefit of using galvanized carbon steel pipes in construction is their versatility. These pipes come in a variety of sizes and thicknesses, making them suitable for a wide range of applications. Whether you need to transport water, gas, or other fluids, galvanized carbon steel pipes can meet your specific requirements.

Moreover, galvanized carbon steel pipes are environmentally friendly. The zinc coating used in the galvanization process is non-toxic and recyclable, making it a sustainable choice for construction projects. By using galvanized carbon steel pipes, builders can reduce their environmental impact and contribute to a more sustainable construction industry.

In terms of cost, galvanized carbon steel pipes are a cost-effective option for construction projects. While they may have a higher upfront cost compared to other types of pipes, their durability and longevity make them a wise investment in the long run. By choosing galvanized carbon steel pipes, builders can save money on maintenance and replacement costs over time.

Overall, the benefits of using galvanized carbon steel pipes in construction projects are clear. From their durability and resistance to damage to their ease of installation and environmental friendliness, these pipes offer numerous advantages that make them a top choice for builders and contractors. Whether you are working on a residential, commercial, or industrial project, galvanized carbon steel pipes can help you achieve your construction goals efficiently and effectively.

How to Properly Maintain and Extend the Lifespan of Galvanized Steel Pipes in Various Applications

Steel pipes are a crucial component in various construction projects, providing structural support and carrying fluids or gases from one point to another. Galvanized carbon steel pipes, in particular, are widely used in construction due to their durability and resistance to corrosion. These pipes are coated with a layer of zinc to protect the underlying steel from rust and other forms of deterioration. Proper maintenance is essential to ensure the longevity and performance of galvanized steel pipes in various applications.

One of the most important steps in maintaining galvanized steel pipes is to regularly inspect them for signs of damage or corrosion. This can be done by visually examining the pipes for any discoloration, rust spots, or flaking of the zinc coating. Any areas that show signs of corrosion should be promptly addressed to prevent further deterioration. In addition to visual inspections, it is also recommended to conduct regular pressure tests to check for leaks or weak spots in the pipes.

Another key aspect of maintaining galvanized steel pipes is to keep them clean and free of debris. Dirt, dust, and other contaminants can accumulate on the surface of the pipes, leading to corrosion and reduced performance. Regular cleaning with a mild detergent and water can help remove these contaminants and preserve the integrity of the zinc coating. It is also important to avoid using abrasive Cleaners or tools that could scratch or damage the surface of the pipes.

In addition to regular inspections and cleaning, it is important to protect galvanized steel pipes from exposure to harsh environmental conditions. Extreme temperatures, moisture, and chemicals can all accelerate the corrosion process and shorten the lifespan of the pipes. To prevent this, it is recommended to install the pipes in a well-ventilated area, away from sources of moisture or corrosive substances. Applying a protective coating or paint to the pipes can also provide an extra layer of defense against corrosion.

Proper installation and handling of galvanized steel pipes are also essential for maintaining their longevity. Pipes should be properly supported and secured to prevent sagging or bending, which can Lead to stress on the joints and potential leaks. It is also important to avoid using excessive force or pressure when connecting or disconnecting pipes, as this can damage the zinc coating and compromise the integrity of the pipes. Following manufacturer guidelines and best practices for installation can help ensure the proper functioning of galvanized steel pipes in various applications.

In conclusion, galvanized carbon steel pipes are a durable and reliable choice for construction projects, thanks to their corrosion-resistant properties. Proper maintenance is essential to extend the lifespan of these pipes and ensure their optimal performance. Regular inspections, cleaning, protection from harsh environmental conditions, and proper installation are all key factors in maintaining galvanized steel pipes. By following these guidelines, contractors and builders can maximize the longevity and efficiency of galvanized steel pipes in various applications.