Table of Contents

Benefits of Stainless Steel Lost Wax Casting in Pipe Fitting Manufacturing

Stainless steel lost wax casting, also known as precision casting, is a popular method used in the manufacturing of Pipe Fittings such as elbows. This process involves creating a wax model of the desired part, coating it in a ceramic shell, and then melting away the wax to leave a hollow ceramic mold. Molten stainless steel is then poured into the mold, creating a precise and intricate final product.

One of the key benefits of using stainless steel lost wax casting in pipe fitting manufacturing is the high level of precision that can be achieved. This method allows for complex shapes and intricate details to be reproduced with accuracy, ensuring that the final product meets the exact specifications required for its intended use. This precision is essential in industries where tight tolerances and exact measurements are crucial, such as in the oil and gas sector.

In addition to precision, stainless steel lost wax casting also offers excellent surface finish quality. The ceramic shell used in the casting process provides a smooth and uniform surface on the final product, reducing the need for additional finishing processes such as sandblasting or Machining. This not only saves time and money but also ensures a high-quality end result that is free from imperfections or defects.

Another advantage of using stainless steel lost wax casting in pipe fitting manufacturing is the ability to produce parts with thin walls and intricate geometries. This method allows for the creation of lightweight yet strong components that are well-suited for applications where weight and space are critical factors. The versatility of stainless steel lost wax casting makes it an ideal choice for a wide range of pipe fitting designs and configurations.

Furthermore, stainless steel is a durable and corrosion-resistant material that is well-suited for use in pipe fittings. Its high strength-to-weight ratio and resistance to rust and corrosion make it an excellent choice for applications where reliability and longevity are essential. Stainless steel lost wax casting ensures that pipe fittings are not only precise and well-finished but also durable and long-lasting, providing a reliable solution for a variety of industrial applications.

In conclusion, stainless steel lost wax casting offers numerous benefits for pipe fitting manufacturing, including precision, surface finish quality, versatility, and durability. This method allows for the creation of complex and intricate parts that meet the exact specifications required for their intended use. With its high level of accuracy and quality, stainless steel lost wax casting is a cost-effective and efficient solution for producing high-quality pipe fittings that meet the demands of modern industries.

Precision Casting Techniques for Carbon Steel Elbows

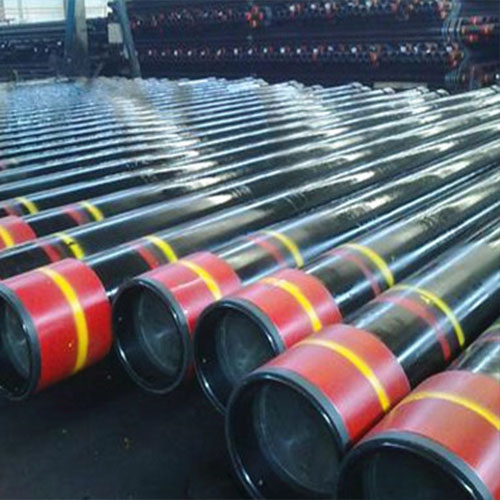

Precision casting techniques have revolutionized the manufacturing industry, allowing for the production of complex and intricate components with high accuracy and precision. One such application of precision casting is in the production of carbon steel elbows for pipe fittings. These elbows play a crucial role in directing the flow of fluids in pipelines, making them essential components in various industries such as oil and gas, chemical, and construction.

Stainless steel/carbon steel lost wax casting, also known as precision casting, is a process that involves creating a wax pattern of the desired component, coating it with a ceramic shell, and then melting away the wax to leave behind a hollow ceramic mold. Molten steel is then poured into the mold, filling the cavity and taking the shape of the wax pattern. Once the steel has solidified, the ceramic shell is broken away, revealing the final product.

One of the key advantages of precision casting is the ability to produce complex shapes and intricate details that would be difficult or impossible to achieve through traditional manufacturing methods. This is particularly important for carbon steel elbows, which often have unique geometries to accommodate the specific requirements of a pipeline system. By using precision casting, manufacturers can create elbows with precise angles, smooth curves, and consistent wall thickness, ensuring optimal performance and durability.

After the casting process is complete, the carbon steel elbows undergo additional finishing processes to achieve the desired surface finish and dimensional accuracy. Sandblasting is commonly used to remove any remaining ceramic shell material and to smooth out any rough surfaces on the casting. This not only improves the aesthetics of the elbow but also ensures that it meets the required specifications for fit and function.

Machining is another critical step in the production of carbon steel elbows, where excess material is removed to achieve the final dimensions and tolerances. Precision machining techniques such as turning, milling, and drilling are used to refine the shape of the elbow and to create any necessary features such as threads or grooves. This step is essential for ensuring that the elbow fits correctly within the pipeline system and can withstand the pressures and stresses it will be subjected to during operation.

Finally, polishing is often performed to enhance the appearance of the carbon steel elbow and to provide a smooth, corrosion-resistant surface finish. Polishing can be done using mechanical methods such as buffing or grinding, or through chemical processes such as electroplating or passivation. This not only improves the aesthetics of the elbow but also helps to protect it from corrosion and wear, extending its service life and ensuring long-term reliability.

In conclusion, stainless steel/carbon steel lost wax casting and precision casting techniques have revolutionized the production of carbon steel elbows for pipe fittings. By utilizing these advanced manufacturing processes, manufacturers can create elbows with complex geometries, precise dimensions, and high-quality surface finishes, ensuring optimal performance and durability in a wide range of industrial applications. From sandblasting to machining to polishing, each step in the production process plays a crucial role in creating high-quality carbon steel elbows that meet the stringent requirements of modern pipeline systems.

Importance of Sandblasting and Machining in Polishing Steel Pipe Fittings

Stainless steel and carbon steel lost wax casting, also known as precision casting, is a popular method for creating steel pipe fittings such as elbows. These fittings are essential components in various industries, including oil and gas, construction, and manufacturing. To ensure the highest quality and performance of these fittings, sandblasting and machining are crucial steps in the polishing process.

Sandblasting is a surface preparation technique that involves propelling abrasive materials at high speeds to clean, smooth, or shape a surface. In the context of steel pipe fittings, sandblasting is used to remove any impurities, scale, or oxidation from the surface of the casting. This process not only improves the appearance of the fitting but also enhances its corrosion resistance and adhesion to coatings.

After sandblasting, machining is performed to achieve precise dimensions and smooth surfaces on the steel pipe fitting. Machining involves cutting, drilling, and shaping the casting using various tools and techniques. This step is essential for ensuring that the fitting meets the required specifications and functions properly when installed in a piping system.

The combination of sandblasting and machining plays a critical role in the overall polishing of steel pipe fittings. Sandblasting prepares the surface of the casting for machining by removing any contaminants that could interfere with the cutting process. Machining, on the other hand, refines the surface of the fitting to achieve the desired finish and dimensions.

One of the key benefits of sandblasting and machining in polishing steel pipe fittings is the improvement in surface quality. By removing impurities and imperfections from the casting, these processes create a smooth and uniform surface that enhances the appearance and performance of the fitting. Additionally, sandblasting and machining help to eliminate any sharp edges or burrs that could cause damage or injury during installation or use.

Another advantage of sandblasting and machining is the enhancement of the fitting’s mechanical properties. By removing surface defects and irregularities, these processes improve the overall strength and durability of the steel pipe fitting. This is particularly important in applications where the fitting is subjected to high pressure, temperature, or corrosive environments.

In conclusion, sandblasting and machining are essential steps in the polishing of stainless steel and carbon steel lost wax casting steel pipe fittings. These processes not only improve the appearance of the fitting but also enhance its corrosion resistance, adhesion to coatings, and mechanical properties. By investing in high-quality sandblasting and Machining Services, manufacturers can ensure that their steel pipe fittings meet the highest standards of quality and performance.