Table of Contents

Benefits of Using Ss400/Q235/Q195/S235/S265jr/L245/L265 ERW/LSAW/SSAW Carbon Welded Steel Pipe for Gas Pipelines

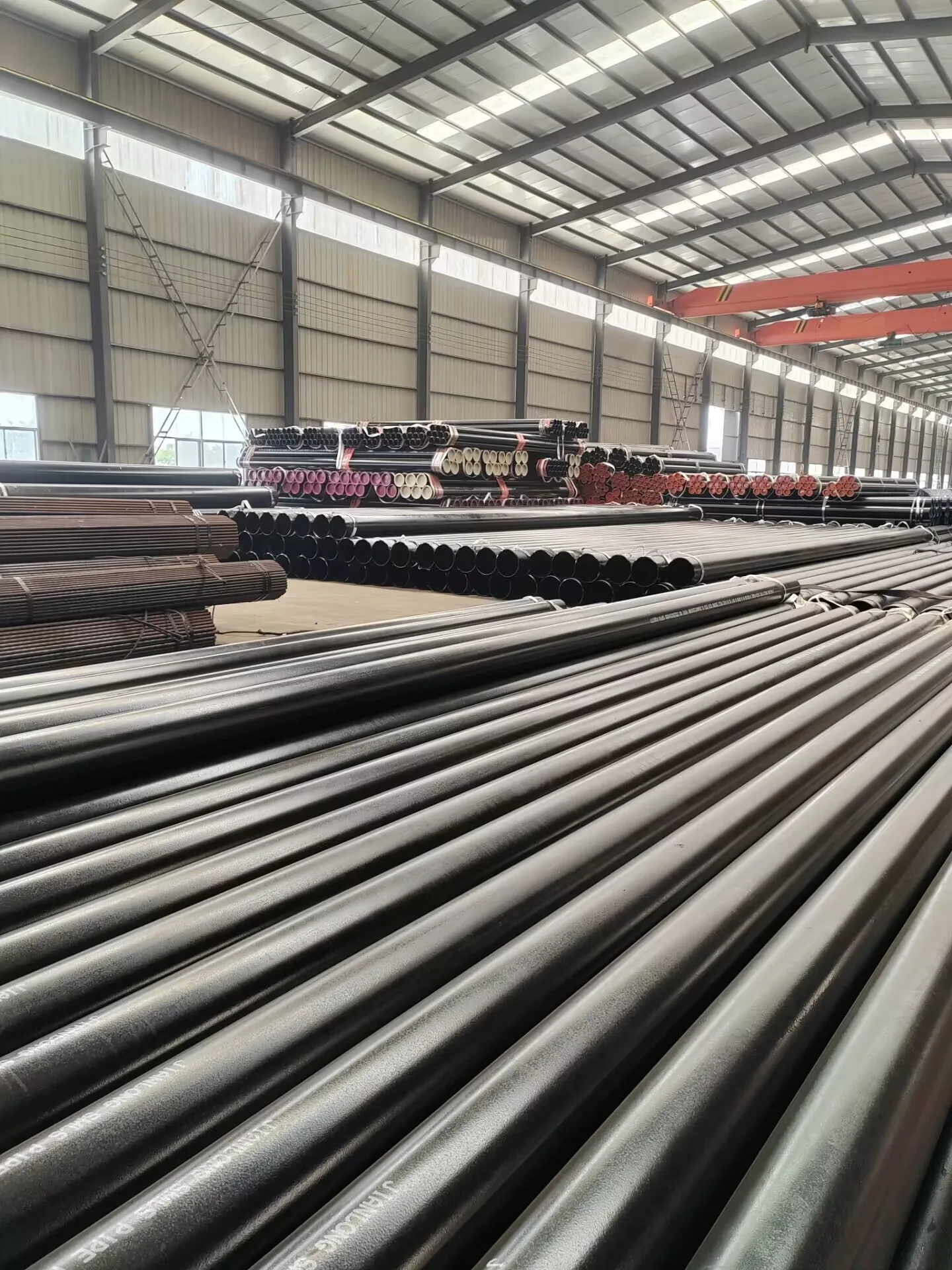

When it comes to constructing gas pipelines, choosing the right materials is crucial to ensure the Safety and efficiency of the system. One popular option that has been widely used in the industry is Ss400/Q235/Q195/S235/S265jr/L245/L265 ERW/LSAW/SSAW carbon welded steel pipe. These pipes offer a range of benefits that make them an ideal choice for gas pipeline construction.

One of the key advantages of using Ss400/Q235/Q195/S235/S265jr/L245/L265 ERW/LSAW/SSAW carbon welded steel pipe is their durability. These pipes are made from high-quality Carbon Steel, which is known for its strength and resilience. This means that they can withstand high pressure and extreme temperatures, making them suitable for use in gas pipelines that are subjected to harsh conditions.

In addition to their durability, Ss400/Q235/Q195/S235/S265jr/L245/L265 ERW/LSAW/SSAW carbon welded Steel Pipes are also highly resistant to corrosion. This is important for gas pipelines, as corrosion can weaken the pipes and Lead to leaks or other issues. By using corrosion-resistant steel pipes, you can ensure the longevity and reliability of your gas pipeline system.

Another benefit of Ss400/Q235/Q195/S235/S265jr/L245/L265 ERW/LSAW/SSAW carbon welded steel pipes is their versatility. These pipes come in a variety of sizes and thicknesses, making them suitable for a wide range of applications. Whether you need to transport Natural Gas, oil, or other fluids, these pipes can be customized to meet your specific requirements.

Furthermore, Ss400/Q235/Q195/S235/S265jr/L245/L265 ERW/LSAW/SSAW carbon welded steel pipes are easy to install and maintain. Their welded construction ensures a tight seal, reducing the risk of leaks and ensuring the efficient flow of gas through the pipeline. Additionally, these pipes require minimal maintenance, saving you time and money in the long run.

In terms of cost-effectiveness, Ss400/Q235/Q195/S235/S265jr/L245/L265 ERW/LSAW/SSAW carbon welded steel pipes are a smart choice for gas pipeline construction. Their durability and resistance to corrosion mean that they have a long service life, reducing the need for frequent replacements or repairs. This can result in significant cost savings over time.

Overall, Ss400/Q235/Q195/S235/S265jr/L245/L265 ERW/LSAW/SSAW carbon welded steel pipes offer a range of benefits that make them an excellent choice for gas pipeline construction. From their durability and corrosion resistance to their versatility and cost-effectiveness, these pipes are a reliable option for ensuring the safety and efficiency of your gas pipeline system. Whether you are building a new pipeline or replacing existing pipes, consider using Ss400/Q235/Q195/S235/S265jr/L245/L265 ERW/LSAW/SSAW carbon welded steel pipes for your next project.

Comparison of Different Types of Sawl Pipes for Gas Pipelines

When it comes to constructing gas pipelines, one of the most critical components is the type of steel pipe used. Among the various options available, Ss400/Q235/Q195/S235 /S265jr/L245/L265 ERW/LSAW/SSAW carbon welded steel pipes are commonly used due to their durability and strength. These pipes are designed to withstand high pressure and extreme conditions, making them ideal for gas transportation.

One of the most popular types of steel pipes used for gas pipelines is the ERW (Electric Resistance Welded) pipe. This type of pipe is made by rolling a steel plate into a cylindrical shape and then welding the edges together. ERW pipes are known for their high strength and durability, making them suitable for gas pipelines that require long-term reliability. Additionally, ERW pipes are cost-effective and easy to install, making them a popular choice among pipeline constructors.

Another type of steel pipe commonly used for gas pipelines is the LSAW (Longitudinal Submerged Arc Welded) pipe. LSAW pipes are made by bending a steel plate into a cylindrical shape and then welding the edges using a submerged arc welding process. This type of pipe is known for its high strength and resistance to corrosion, making it ideal for gas pipelines that are exposed to harsh environmental conditions. Additionally, LSAW pipes have a smooth surface finish, which reduces friction and allows for efficient gas flow.

https://www.youtube.com/watch?v=kcGBRz7l738SSAW (Spiral Submerged Arc Welded) pipes are also commonly used for gas pipelines. These pipes are made by forming a steel strip into a spiral shape and then welding the edges together using a submerged arc welding process. SSAW pipes are known for their high strength and flexibility, making them suitable for gas pipelines that require a high degree of bendability. Additionally, SSAW pipes have a uniform wall thickness, which ensures consistent gas flow and reduces the risk of leaks.

When comparing the different types of sawl pipes for gas pipelines, it is essential to consider factors such as strength, durability, corrosion resistance, and cost. ERW pipes are known for their high strength and cost-effectiveness, making them a popular choice among pipeline constructors. LSAW pipes are preferred for their resistance to corrosion and smooth surface finish, while SSAW pipes are known for their flexibility and uniform wall thickness.

In conclusion, Ss400/Q235/Q195/S235 /S265jr/L245/L265 ERW/LSAW/SSAW carbon welded steel pipes are widely used for gas pipelines due to their strength, durability, and resistance to corrosion. Each type of pipe has its advantages and disadvantages, so it is essential to consider the specific requirements of the gas pipeline before choosing the most suitable type of pipe. By understanding the differences between ERW, LSAW, and SSAW pipes, pipeline constructors can make informed decisions that ensure the safe and efficient transportation of gas.