Table of Contents

Benefits of Using Spiral Submerged Arc Welding Pipe for Marine Water Conveyance

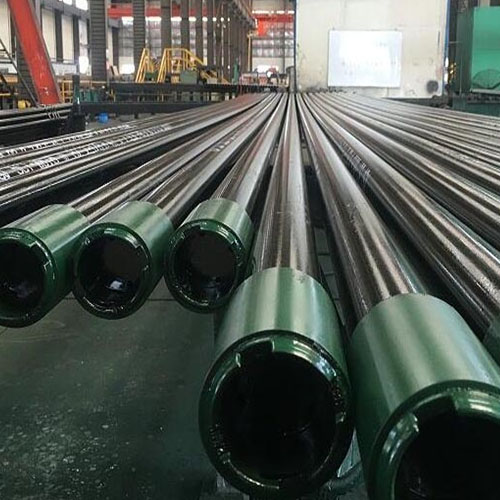

Spiral submerged arc welding (SSAW) pipe is a popular choice for marine water conveyance due to its numerous benefits. This type of pipe is made by forming a spiral seam along the length of the pipe, which is then welded using the submerged arc welding process. The result is a strong and durable pipe that is ideal for use in marine environments.

One of the key benefits of using SSAW pipe for marine water conveyance is its high strength. The spiral seam design of the pipe helps to distribute the stress evenly along the length of the pipe, making it less likely to fail under pressure. This is crucial for applications in marine environments, where pipes are often subjected to high Levels of pressure and stress.

In addition to its high strength, SSAW pipe is also highly resistant to corrosion. The welding process used to create SSAW pipe results in a smooth and uniform surface that is less prone to corrosion than other types of welded pipe. This makes SSAW pipe an ideal choice for use in marine environments, where exposure to saltwater can quickly corrode traditional pipes.

Another benefit of using SSAW pipe for marine water conveyance is its versatility. SSAW pipe can be manufactured in a wide range of sizes and thicknesses, making it suitable for a variety of marine applications. Whether you need a small diameter pipe for a residential water supply system or a large diameter pipe for a commercial water conveyance project, SSAW pipe can be customized to meet your specific requirements.

Furthermore, SSAW pipe is easy to install and maintain, making it a cost-effective choice for marine water conveyance projects. The spiral seam design of the pipe allows for quick and efficient installation, reducing labor costs and minimizing downtime. Additionally, the smooth surface of SSAW pipe makes it easy to clean and maintain, further reducing maintenance costs over the life of the pipe.

In conclusion, spiral submerged arc welding pipe offers numerous benefits for marine water conveyance projects. Its high strength, corrosion resistance, versatility, and cost-effectiveness make it an ideal choice for applications in marine environments. Whether you are building a residential water supply system or a commercial water conveyance project, SSAW pipe can be customized to meet your specific requirements and provide reliable performance for years to come. Consider using SSAW pipe for your next marine water conveyance project and experience the benefits for yourself.

Installation Process of Spiral Submerged Arc Welding Pipe in Marine Environments

Spiral submerged arc welding (SSAW) pipes are widely used in marine environments for water conveyance due to their high strength, durability, and corrosion resistance. The installation process of SSAW pipes in marine environments requires careful planning and execution to ensure the longevity and efficiency of the water conveyance system.

The first step in the installation process of SSAW pipes in marine environments is to conduct a thorough site survey to assess the conditions of the seabed and determine the optimal route for laying the pipes. This involves analyzing the depth of the water, the presence of any Obstacles or obstructions, and the soil composition to ensure that the pipes are installed securely and will not be damaged by external factors.

Once the site survey is complete, the next step is to prepare the pipes for installation. This involves coating the pipes with a protective layer to prevent corrosion and ensure their longevity in the harsh marine Environment. The coating also helps to reduce friction during installation and improve the flow of water through the pipes.

After the pipes are prepared, they are transported to the installation site and laid on the seabed using specialized equipment such as pipe-laying vessels or Barges. The pipes are then welded together using the spiral submerged arc welding technique, which involves feeding the pipes through a welding machine that Fuses the seams together using a continuous welding process.

https://www.youtube.com/watch?v=kcGBRz7l738During the welding process, it is important to ensure that the pipes are aligned properly and that the welds are of high quality to prevent leaks and ensure the structural integrity of the water conveyance system. Quality control measures such as non-destructive testing and visual inspections are carried out to verify the integrity of the welds and ensure that the pipes meet the required standards.

Once the welding process is complete, the next step is to backfill the trench where the pipes are laid to secure them in place and protect them from external forces such as currents and waves. The backfill material is carefully selected to provide adequate support for the pipes and prevent them from shifting or becoming damaged.

After the backfilling is complete, the final step in the installation process is to conduct pressure testing to ensure that the water conveyance system is leak-proof and can withstand the operating pressures. This involves pressurizing the pipes with water or air and monitoring for any leaks or pressure drops that could indicate a problem with the installation.

In conclusion, the installation process of spiral submerged arc welding pipes in marine environments requires careful planning, preparation, and execution to ensure the longevity and efficiency of the water conveyance system. By following the proper procedures and quality control measures, the installation of SSAW pipes can provide a reliable and durable solution for Transporting water in marine environments.

Maintenance Tips for Spiral Submerged Arc Welding Pipe Used in Marine Water Conveyance

Spiral submerged arc welding (SSAW) pipes are commonly used in marine water conveyance systems due to their durability and resistance to corrosion. These pipes are designed to withstand the harsh conditions of marine environments, making them an ideal choice for transporting water over long distances. However, like any other type of pipe, SSAW pipes require regular maintenance to ensure optimal performance and longevity.

One of the most important maintenance tasks for SSAW pipes used in marine water conveyance is regular inspection. Inspecting the pipes for signs of corrosion, leaks, or other damage is crucial to prevent potential issues that could Lead to costly repairs or replacements. It is recommended to conduct visual inspections of the pipes at least once a year, and more frequently if the pipes are exposed to particularly harsh conditions.

In addition to visual inspections, it is also important to monitor the internal condition of the pipes. This can be done through various methods, such as using cameras or Sensors to detect any buildup of sediment or other debris that could impede the flow of water. Regular cleaning of the pipes may be necessary to prevent blockages and ensure smooth water conveyance.

Another important maintenance task for SSAW pipes used in marine water conveyance is corrosion protection. Marine environments are particularly corrosive due to the presence of saltwater, which can accelerate the corrosion process. To protect the pipes from corrosion, it is recommended to apply a protective coating or lining to the exterior of the pipes. This coating should be inspected regularly and reapplied as needed to ensure continued protection.

In addition to external corrosion protection, it is also important to prevent internal corrosion of the pipes. This can be achieved through the use of corrosion inhibitors or by maintaining proper water chemistry to prevent the formation of corrosive compounds. Regular water quality testing can help identify any potential issues and allow for corrective action to be taken before damage occurs.

Proper handling and storage of SSAW pipes is also essential for maintaining their integrity and preventing damage. Pipes should be stored in a dry, well-ventilated area to prevent rusting and other forms of corrosion. Care should also be taken when handling the pipes to avoid dents, scratches, or other forms of physical damage that could compromise their structural integrity.

Regular maintenance of SSAW pipes used in marine water conveyance is essential to ensure their continued performance and longevity. By conducting regular inspections, monitoring internal conditions, protecting against corrosion, and practicing proper handling and storage techniques, you can help extend the life of your pipes and prevent costly repairs or replacements. Remember, prevention is always better than cure when it comes to maintaining the integrity of your water conveyance system.