Table of Contents

The Benefits of Using SMLS Pipe API 5L for Industrial Applications

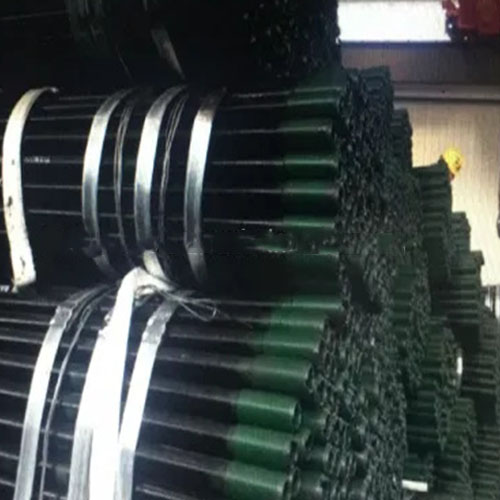

SMLS Pipe API 5L, also known as seamless pipe, is a type of low Carbon Steel pipe that is commonly used in industrial applications. It is manufactured using a seamless process, which means that there are no welded seams or joints in the pipe. This results in a smooth and uniform surface, as well as a higher strength and durability compared to welded pipes.

One of the main benefits of using SMLS Pipe API 5L is its superior strength and durability. Because there are no welded seams, the pipe is able to withstand higher Levels of pressure and stress, making it ideal for use in high-pressure and high-temperature applications. This makes it a popular choice for industries such as oil and gas, petrochemical, and power generation, where the pipes are subjected to extreme conditions.

In addition to its strength and durability, SMLS Pipe API 5L also offers excellent corrosion resistance. The seamless manufacturing process eliminates the need for welding, which can create weak points in the pipe that are susceptible to corrosion. This makes the pipe suitable for use in environments where corrosion is a concern, such as in offshore drilling operations or chemical processing plants.

Another advantage of using SMLS Pipe API 5L is its smooth and uniform surface. Because the pipe is manufactured without any welded seams, it has a consistent diameter and thickness throughout its length. This allows for better flow of fluids and gases through the pipe, reducing the risk of blockages and pressure drops. It also makes the pipe easier to clean and maintain, which is important in industries where hygiene and cleanliness are a priority.

Furthermore, SMLS Pipe API 5L is available in a variety of sizes and specifications, making it suitable for a wide range of industrial applications. It can be used for Transporting liquids, gases, and solids, as well as for structural and mechanical purposes. This versatility makes it a cost-effective solution for many different types of projects, as it eliminates the need for multiple types of pipes to be used.

In conclusion, SMLS Pipe API 5L offers a range of benefits for industrial applications. Its seamless manufacturing process results in a strong, durable, and corrosion-resistant pipe that is suitable for use in high-pressure and high-temperature environments. Its smooth and uniform surface allows for better flow and easier maintenance, while its versatility makes it a cost-effective solution for a wide range of projects. Whether it’s for transporting fluids, gases, or solids, or for structural and mechanical purposes, SMLS Pipe API 5L is a reliable and efficient choice for industrial piping needs.

Understanding the Differences Between ASTM A106 Gr. B and A53 Gr. B Sch40 Sch80 Seamless Low Carbon Steel Pipe

When it comes to choosing the right type of seamless low carbon steel pipe for your project, it’s important to understand the differences between ASTM A106 Gr. B and A53 Gr. B Sch40 Sch80. These two types of pipes are commonly used in various industries, including oil and gas, petrochemical, and construction. Understanding the distinctions between them can help you make an informed decision and ensure that you select the most suitable option for your specific needs.

One of the key differences between ASTM A106 Gr. B and A53 Gr. B Sch40 Sch80 seamless low carbon Steel Pipes is their manufacturing process. ASTM A106 Gr. B pipes are manufactured using the hot-finished or cold-drawn process, while A53 Gr. B pipes are produced using the electric resistance welded (ERW) process. This variance in manufacturing methods results in differences in the mechanical properties and performance of the two types of pipes.

In terms of mechanical properties, ASTM A106 Gr. B pipes have higher tensile strength and yield strength compared to A53 Gr. B pipes. This makes them more suitable for high-temperature and high-pressure applications, such as in the oil and gas industry. On the other hand, A53 Gr. B pipes are more commonly used in low-pressure and low-temperature applications, such as in plumbing and HVAC Systems.

Another important distinction between ASTM A106 Gr. B and A53 Gr. B Sch40 Sch80 seamless low carbon steel pipes is their chemical composition. ASTM A106 Gr. B pipes are required to adhere to specific chemical composition requirements, including a maximum carbon content of 0.30%, manganese content of 0.29-1.06%, and phosphorus and sulfur content of 0.035%. A53 Gr. B pipes, on the other hand, have less stringent chemical composition requirements, with a maximum carbon content of 0.30%, manganese content of 1.20%, and phosphorus and sulfur content of 0.05%.

When it comes to dimensional tolerances, ASTM A106 Gr. B and A53 Gr. B Sch40 Sch80 seamless low carbon steel pipes also have differences. ASTM A106 Gr. B pipes are required to adhere to tighter dimensional tolerances, particularly in terms of wall thickness and outside diameter, compared to A53 Gr. B pipes. This makes A106 Gr. B pipes more suitable for applications where precise dimensions are critical, such as in structural and mechanical applications.

In conclusion, understanding the differences between ASTM A106 Gr. B and A53 Gr. B Sch40 Sch80 seamless low carbon steel pipes is crucial for selecting the right type of pipe for your project. Consider factors such as manufacturing process, mechanical properties, chemical composition, and dimensional tolerances to make an informed decision. By doing so, you can ensure that you choose a pipe that meets your specific requirements and delivers optimal performance in your application.