Table of Contents

Преимущества использования сверхпрочных антикоррозионных цилиндрических труб из кованой дуплексной стали на морских нефтяных платформах

Морские нефтяные вышки подвергаются суровым условиям окружающей среды, включая соленую воду, высокое давление и экстремальные температуры. Эти условия могут привести к коррозии и деградации оборудования, что может привести к дорогостоящему ремонту и простою. Чтобы справиться с этими проблемами, многие операторы морских нефтяных вышек обращаются к сверхпрочным антикоррозионным цилиндрическим трубам из кованой дуплексной стали.

Кованая дуплексная сталь — это тип нержавеющей стали, который обеспечивает превосходную прочность и коррозионную стойкость по сравнению с традиционной углеродистой сталью. Это делает его идеальным материалом для использования на морских нефтяных вышках, где оборудование постоянно подвергается воздействию агрессивных элементов. Процесс ковки еще больше повышает прочность и долговечность стали, что делает ее способной выдерживать высокое давление и экстремальные условия.

Одним из ключевых преимуществ использования сверхпрочных антикоррозионных кованых стальных цилиндрических трубок из дуплексной стали на морских нефтяных вышках является их устойчивость к коррозии. Соленая вода является распространенной причиной коррозии в морской среде, но кованая дуплексная сталь обладает высокой устойчивостью к коррозии, что делает ее идеальным выбором для оборудования, которое постоянно подвергается воздействию соленой воды. Такая устойчивость к коррозии помогает продлить срок службы оборудования и снизить потребность в частом техническом обслуживании и ремонте. Помимо коррозионной стойкости, сверхпрочные антикоррозионные цилиндрические трубы из кованой дуплексной стали также обладают превосходной прочностью и долговечностью. Это особенно важно на морских нефтяных вышках, где оборудование подвергается высокому давлению и экстремальным условиям. Прочность кованой дуплексной стали позволяет ей выдерживать суровые условия морских операций, обеспечивая поддержание оборудования в оптимальном состоянии и снижая риск его выхода из строя. к усталости и растрескиванию. Это важно для морских нефтяных вышек, где оборудование подвергается постоянным нагрузкам и нагрузкам. Превосходная усталостная прочность кованой дуплексной стали помогает предотвратить растрескивание и выход из строя оборудования, обеспечивая безопасность и надежность работы на буровой установке.

Еще одним преимуществом использования сверхпрочных антикоррозионных цилиндрических труб из кованой дуплексной стали на морских нефтяных вышках является их экономическая эффективность. Хотя первоначальная стоимость кованой дуплексной стали может быть выше, чем у традиционной углеродистой стали, долгосрочная экономия на техническом обслуживании и ремонте делает ее экономически эффективным выбором для морских операций. Инвестируя в высококачественное оборудование, изготовленное из кованой дуплексной стали, операторы морских нефтяных вышек могут сократить время простоя и затраты на техническое обслуживание, что в конечном итоге сэкономит деньги в долгосрочной перспективе.

В целом преимущества использования сверхмощных антикоррозионных баллонов из кованой дуплексной стали трубы на морских нефтяных вышках чистые. От превосходной коррозионной стойкости до прочности, долговечности и экономической эффективности кованая дуплексная сталь предлагает ряд преимуществ, которые делают ее идеальным выбором для оборудования в морских условиях. Инвестируя в высококачественное оборудование, изготовленное из кованой дуплексной стали, операторы морских нефтяных вышек могут обеспечить безопасность, надежность и эффективность своей деятельности, что в конечном итоге приведет к повышению производительности и прибыльности.

Советы по техническому обслуживанию для продления срока службы сверхмощных антикоррозионных цилиндрических труб из кованой дуплексной стали на морских нефтяных платформах

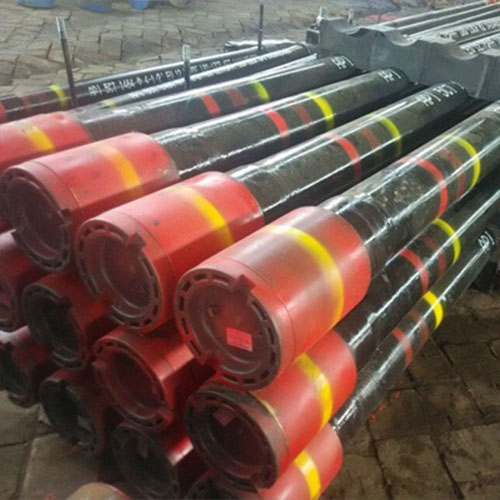

Морские нефтяные вышки подвергаются суровым условиям окружающей среды, включая воздействие соленой воды, высоких температур и агрессивных химикатов. В результате оборудование, используемое на этих буровых установках, должно выдерживать такие условия, чтобы обеспечить безопасную и эффективную работу. Одним из важнейших компонентов морских нефтяных вышек является цилиндрическая труба, которая используется в различных приложениях, таких как бурение, перекачка и подъем тяжелого оборудования.

Для борьбы с коррозионным воздействием морской среды на многих нефтяных вышках используются сверхпрочные антикоррозионные цилиндрические трубы из кованой дуплексной стали. Эти трубы изготовлены из особого типа стали, обеспечивающего превосходную коррозионную стойкость по сравнению с традиционными стальными сплавами. Процесс ковки еще больше повышает прочность и долговечность трубок, что делает их идеальными для использования в морских условиях.

Несмотря на прочную конструкцию, сверхпрочные противокоррозионные цилиндрические трубки из кованой дуплексной стали по-прежнему требуют регулярного обслуживания для обеспечения их долговечности и производительности. . Вот несколько советов по техническому обслуживанию, которые помогут продлить срок службы этих важнейших компонентов морских нефтяных вышек.

Прежде всего, регулярные проверки необходимы для раннего выявления любых признаков коррозии или повреждений. Осмотрите трубки цилиндров на наличие признаков ржавчины, точечной коррозии или трещин, поскольку они могут указывать на потенциальные проблемы, которые необходимо устранить. Также важно проверять наличие каких-либо утечек или ненормального износа, которые могут повлиять на работу трубок.

В дополнение к визуальному осмотру рекомендуется провести неразрушающий контроль (NDT) трубок цилиндров, чтобы обнаружить любые скрытые дефекты, которые не видны невооруженным глазом. Методы неразрушающего контроля, такие как ультразвуковой контроль, магнитно-порошковый контроль и дефектоскопия, могут помочь выявить любые дефекты или слабые места в трубах, которые могут поставить под угрозу их целостность. цилиндрические трубки. Соленая вода, грязь и другие загрязнения могут накапливаться на поверхности трубок, что со временем приводит к коррозии и разрушению. Регулярно очищайте трубки мягким моющим средством и мягкой щеткой, уделяя особое внимание участкам, склонным к коррозии.

После очистки важно нанести защитное покрытие на трубки цилиндров, чтобы предотвратить коррозию и продлить срок их службы. Доступны различные типы антикоррозионных покрытий, в том числе эпоксидные, полиуретановые и покрытия с высоким содержанием цинка, которые могут обеспечить дополнительный уровень защиты от суровых морских условий.

Помимо регулярного технического обслуживания также важно соблюдать соблюдение правил установки и эксплуатации для предотвращения преждевременного износа и повреждения трубок цилиндров. Убедитесь, что трубки установлены правильно и что они эксплуатируются в указанных пределах, чтобы избежать перегрузки или чрезмерной нагрузки на компоненты.

Следуя этим советам по техническому обслуживанию, морские нефтяные вышки могут обеспечить долговечность и производительность своих сверхпрочных антикоррозионных трубок цилиндров из кованой дуплексной стали. Регулярные проверки, очистка, нанесение защитных покрытий, а также правильная установка и эксплуатация необходимы для продления срока службы этих критически важных компонентов и обеспечения безопасности и эффективности морских операций.