Table of Contents

Benefits of Using Artificial Fibers for Highway Roadways

Highways are essential infrastructure that connects cities and facilitates the movement of goods and people. As such, it is crucial to ensure that these roadways are durable and can withstand the heavy traffic they experience daily. One way to enhance the strength and longevity of highways is by incorporating artificial fibers into the concrete used for construction.

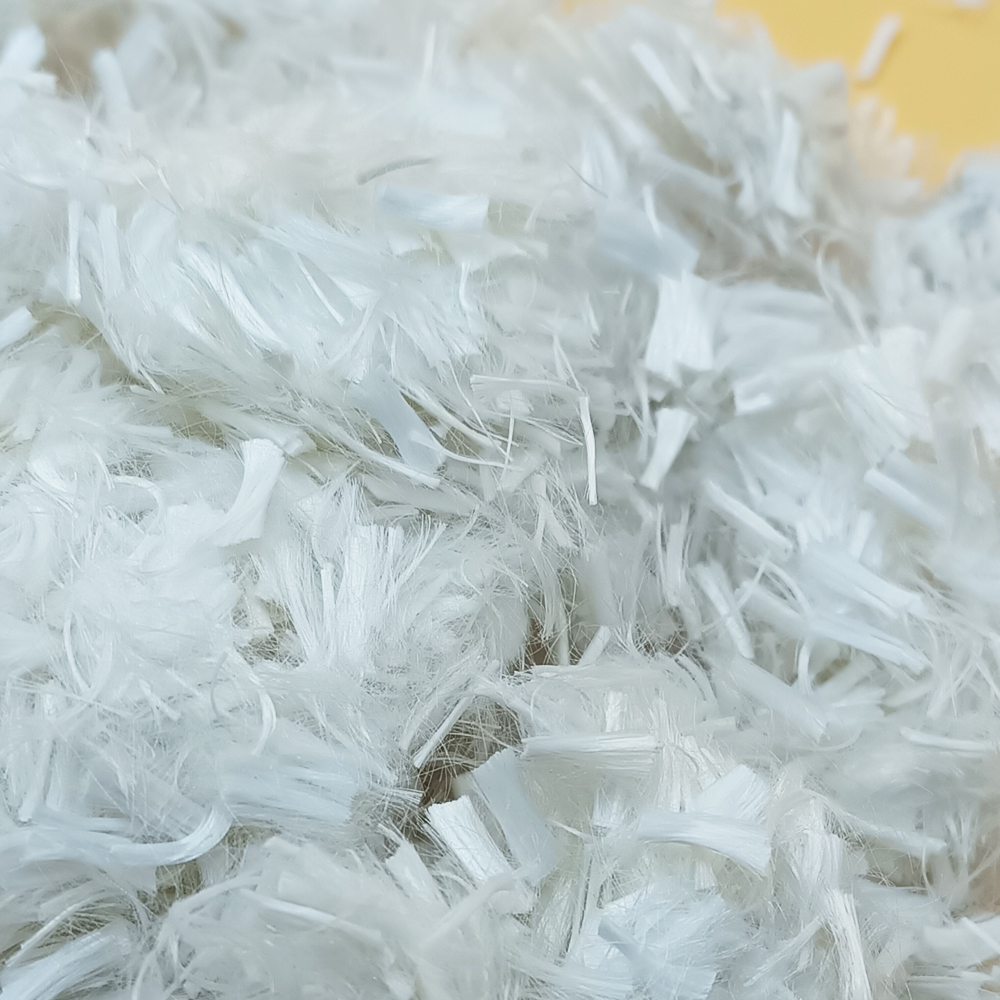

Artificial fibers, such as polypropylene and polyester, are commonly used in highway construction to improve the performance of concrete. These fibers are added to the concrete mix during the mixing process and help to enhance the properties of the concrete. One of the main benefits of using artificial fibers in highway roadways is their ability to increase the tensile strength of the concrete. This means that the concrete is less likely to crack or break under heavy loads, reducing the need for costly repairs and maintenance.

| Nr. | Product Name |

| 1 | for Roadway Polyester Fiber for pavement |

In addition to improving the tensile strength of the concrete, artificial fibers also help to control cracking. Cracking in concrete can occur due to a variety of factors, including temperature changes, shrinkage, and traffic loads. By adding artificial fibers to the concrete mix, the likelihood of cracking is reduced, leading to a more durable and long-lasting roadway.

Another benefit of using artificial fibers in highway roadways is their ability to improve the overall performance of the concrete. These fibers help to enhance the durability and abrasion resistance of the concrete, making it more resistant to wear and tear from heavy traffic. This results in a longer service life for the roadway, reducing the need for frequent repairs and replacements.

Furthermore, artificial fibers can also help to improve the workability of the concrete mix. By adding fibers to the mix, the concrete becomes more cohesive and easier to place and finish. This can help to reduce construction time and costs, as well as improve the overall quality of the finished roadway.

Overall, the use of artificial fibers in highway roadways offers a wide range of benefits, including increased tensile strength, improved crack control, enhanced performance, and improved workability. These benefits can help to create more durable and long-lasting roadways that can withstand the demands of heavy traffic and harsh environmental conditions.

In conclusion, artificial fibers are a valuable tool in highway construction, offering a range of benefits that can help to improve the strength, durability, and performance of concrete roadways. By incorporating artificial fibers into the concrete mix, highway engineers can create roadways that are more resilient, cost-effective, and sustainable in the long run. As technology continues to advance, the use of artificial fibers in highway construction is likely to become even more widespread, leading to safer and more reliable roadways for all.

The Advantages of Concrete Fiber in Road Construction

Concrete fiber is a material that has been gaining popularity in road construction due to its numerous advantages. This innovative material is made by adding synthetic fibers, such as polypropylene or nylon, to the concrete mix. The result is a stronger and more durable road surface that can withstand heavy traffic and harsh weather conditions.

One of the main advantages of using concrete fiber in road construction is its ability to reduce cracking. Traditional concrete roads are prone to cracking due to factors such as temperature changes, heavy loads, and settlement. However, the addition of fibers helps to distribute stress more evenly throughout the concrete, reducing the likelihood of cracks forming. This not only improves the longevity of the road but also reduces the need for costly repairs and maintenance.

In addition to reducing cracking, concrete fiber also improves the overall strength of the road surface. The fibers act as reinforcement, increasing the tensile strength of the concrete and making it more resistant to bending and breaking. This results in a road that can better withstand the weight of heavy vehicles and the impact of traffic loads, leading to a longer service life and lower maintenance costs.

Another advantage of using concrete fiber in road construction is its ability to improve the durability of the road surface. The fibers help to prevent the formation of ruts and potholes by enhancing the wear resistance of the concrete. This means that the road will maintain a smoother and more even surface over time, reducing the risk of accidents and improving the overall driving experience for motorists.

Furthermore, concrete fiber is also beneficial for the Environment. By using synthetic fibers in road construction, less natural resources such as gravel and Sand are required, reducing the environmental impact of road building. Additionally, the longer lifespan of concrete fiber roads means that fewer materials will need to be extracted and processed for road maintenance and repairs, further reducing the carbon footprint of the transportation industry.

Overall, the advantages of using concrete fiber in road construction are clear. From reducing cracking and improving strength to enhancing durability and sustainability, this innovative material offers a range of benefits for both road builders and motorists alike. As the demand for more resilient and long-lasting road surfaces continues to grow, concrete fiber is likely to play an increasingly important role in the future of highway construction. By incorporating this material into road projects, we can create safer, more reliable, and more sustainable transportation infrastructure for generations to come.