Table of Contents

Benefits of Using S235J2 and S275J2 Seamless Steel Pipes for Oil Pipeline Construction

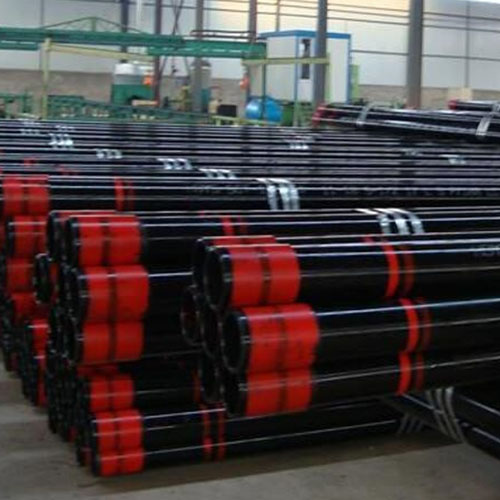

Oil pipelines are a crucial component of the infrastructure that allows for the transportation of oil from production sites to refineries and distribution centers. When it comes to constructing oil pipelines, the choice of materials is of utmost importance. Seamless steel pipes, such as the S235J2 and S275J2 grades, are popular choices for oil pipeline construction due to their durability, strength, and resistance to corrosion.

One of the key benefits of using S235J2 and S275J2 seamless steel pipes for oil pipeline construction is their high tensile strength. These grades of steel have a minimum yield strength of 235 MPa and 275 MPa, respectively, making them ideal for withstanding the high pressures and stresses that oil pipelines are subjected to during operation. This high tensile strength ensures that the pipelines can safely transport oil over long distances without the risk of failure or leakage.

In addition to their high tensile strength, S235J2 and S275J2 seamless steel pipes also offer excellent resistance to corrosion. Oil pipelines are often exposed to harsh environmental conditions, including moisture, Chemicals, and varying temperatures, which can cause corrosion and deterioration of the pipeline material over time. By using corrosion-resistant steel grades like S235J2 and S275J2, pipeline operators can ensure the longevity and reliability of their infrastructure, reducing the need for costly maintenance and repairs.

Another advantage of using S235J2 and S275J2 seamless steel pipes for oil pipeline construction is their uniformity and consistency in terms of dimensions and properties. Seamless steel pipes are manufactured through a process that involves heating a solid steel billet and then stretching it to form a seamless tube. This manufacturing process results in pipes that have a smooth surface finish and precise dimensions, ensuring a tight and leak-free fit when connecting pipe sections together. This uniformity in dimensions and properties is essential for maintaining the integrity and efficiency of the oil pipeline system.

Furthermore, S235J2 and S275J2 seamless steel pipes are known for their versatility and adaptability to different types of oil pipeline applications. These steel grades can be easily welded, bent, and fabricated to meet the specific requirements of a pipeline project, whether it involves Transporting Crude Oil, Natural Gas, or refined petroleum products. This flexibility in design and construction allows for the customization of oil pipelines to suit the unique needs and challenges of each project, ensuring optimal performance and efficiency.

https://www.youtube.com/watch?v=mlDSyUP5RK0In conclusion, the use of S235J2 and S275J2 seamless steel pipes for oil pipeline construction offers a wide range of benefits, including high tensile strength, corrosion resistance, uniformity in dimensions and properties, and versatility in design. These steel grades are well-suited for the demanding conditions and requirements of oil pipeline applications, providing a reliable and cost-effective solution for transporting oil safely and efficiently. By choosing S235J2 and S275J2 seamless steel pipes, pipeline operators can ensure the long-term integrity and performance of their infrastructure, ultimately contributing to the sustainability and success of the oil industry.