Inhoudsopgave

Benefits of Using Liquid Stripping Resistance Additives in Bitumen Stability

Bitumen, a crucial component in the construction industry, is used in various applications such as road paving, roofing, and waterproofing. However, one of the major challenges faced by bitumen is its susceptibility to stripping, which occurs when the bond between the bitumen and the aggregate is weakened due to the presence of moisture. This can Lead to premature pavement failure and reduced durability of the asphalt mix. To address this issue, liquid stripping resistance additives have been developed to improve the stability of bitumen and enhance its performance in various applications.

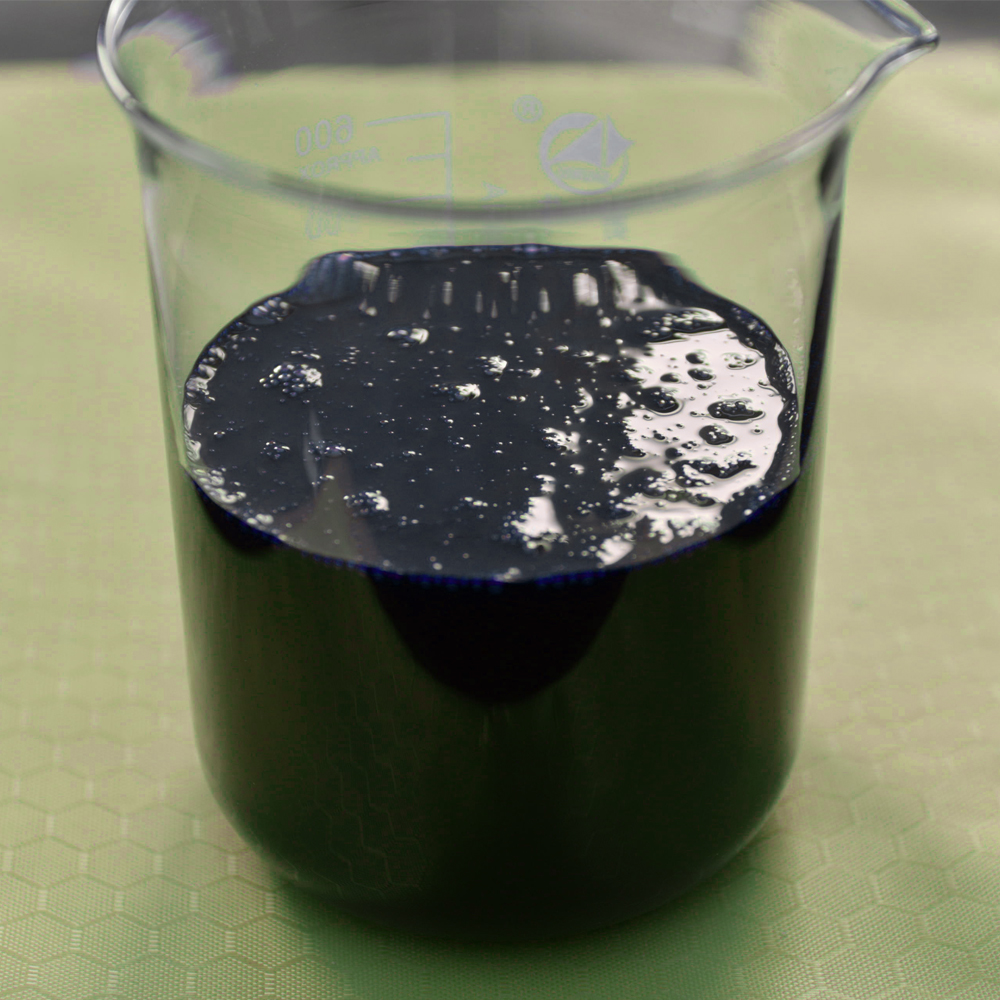

Liquid stripping resistance additives are chemical compounds that are added to bitumen to improve its adhesion to aggregates and reduce the risk of moisture-induced damage. These additives work by forming a protective film around the bitumen particles, preventing water from penetrating and causing stripping. By enhancing the adhesion between the bitumen and the aggregate, liquid stripping resistance additives help to create a more durable and long-lasting asphalt mix.

One of the key benefits of using liquid stripping resistance additives is improved bitumen stability. These additives help to enhance the cohesive properties of bitumen, making it less susceptible to moisture damage and improving its overall performance in various applications. By reducing the risk of stripping, liquid stripping resistance additives can help to extend the service life of asphalt pavements and reduce maintenance costs over time.

In addition to improving bitumen stability, liquid stripping resistance additives also offer other benefits such as increased resistance to rutting and cracking. By enhancing the adhesion between the bitumen and the aggregate, these additives help to create a stronger and more flexible asphalt mix that can better withstand the stresses and strains of heavy traffic and harsh weather conditions. This can help to improve the overall performance of asphalt pavements and reduce the need for costly repairs and maintenance.

Furthermore, liquid stripping resistance additives can also help to improve the workability of bitumen during the mixing and laying process. These additives can help to reduce the viscosity of bitumen, making it easier to handle and apply on the job site. This can help to improve the efficiency of the construction process and ensure a more uniform and consistent asphalt mix that meets the required specifications.

Overall, the use of liquid stripping resistance additives can offer significant benefits in improving bitumen stability and enhancing the performance of asphalt pavements. By reducing the risk of moisture-induced damage, increasing resistance to rutting and cracking, and improving workability, these additives can help to create more durable and long-lasting asphalt mixes that meet the demands of modern construction projects. As the construction industry continues to evolve, the use of liquid stripping resistance additives will play an increasingly important role in ensuring the quality and longevity of asphalt pavements.

How to Choose the Right Liquid Stripping Resistance Additive for Improved Bitumen Stability

Bitumen is a crucial component in the construction industry, used in the production of asphalt for roads, highways, and other infrastructure projects. However, one of the challenges faced by engineers and contractors is the susceptibility of bitumen to stripping, a phenomenon where the binder is separated from the aggregate due to the presence of moisture. This can lead to premature pavement failure and increased maintenance costs. To address this issue, liquid stripping resistance additives have been developed to improve the stability of bitumen and enhance its performance in various applications.

When choosing the right liquid stripping resistance additive for improved bitumen stability, it is essential to consider several factors. Firstly, the compatibility of the additive with the bitumen binder is crucial. The additive should be able to mix well with the bitumen without causing any adverse reactions or compromising the properties of the binder. It is recommended to conduct compatibility tests to ensure that the additive is suitable for the specific type of bitumen being used.

| No. | Article Name |

| 1 | Asphalt anti-stripping additive |

Another important factor to consider is the dosage of the additive. The effectiveness of the additive in preventing stripping depends on the concentration used. It is essential to follow the manufacturer’s recommendations regarding the dosage and application method to achieve the desired results. Overdosing or underdosing the additive can lead to ineffective performance and may even have negative consequences on the overall quality of the asphalt mix.

Furthermore, the performance of the additive under different environmental conditions should be taken into account. Bitumen is exposed to a wide range of temperatures and moisture Levels during its service life, and the additive should be able to provide consistent protection against stripping under varying conditions. It is advisable to choose an additive that has been tested and proven to perform well in different climates and environments.

In addition to performance, the cost-effectiveness of the additive should also be considered. While it is important to invest in high-quality additives to ensure the durability and longevity of the asphalt pavement, it is equally important to choose additives that offer good value for money. Conducting a cost-benefit analysis can help determine the most cost-effective option that meets the project requirements and budget constraints.

When selecting a liquid stripping resistance additive, it is also essential to consider the ease of handling and application. The additive should be easy to mix with the bitumen and should not require any special equipment or procedures for application. This can help streamline the construction process and reduce labor costs associated with handling and applying the additive.

In conclusion, choosing the right liquid stripping resistance additive is crucial for improving the stability of bitumen and enhancing the performance of asphalt pavements. By considering factors such as compatibility, dosage, performance under different conditions, cost-effectiveness, and ease of handling, engineers and contractors can select additives that offer optimal protection against stripping and ensure the long-term durability of the pavement. Conducting thorough research and consulting with experts in the field can help make informed decisions and achieve successful outcomes in asphalt construction projects.