Inhoudsopgave

Benefits of Using Bitumen Anti-Rutting Additives in Street Construction

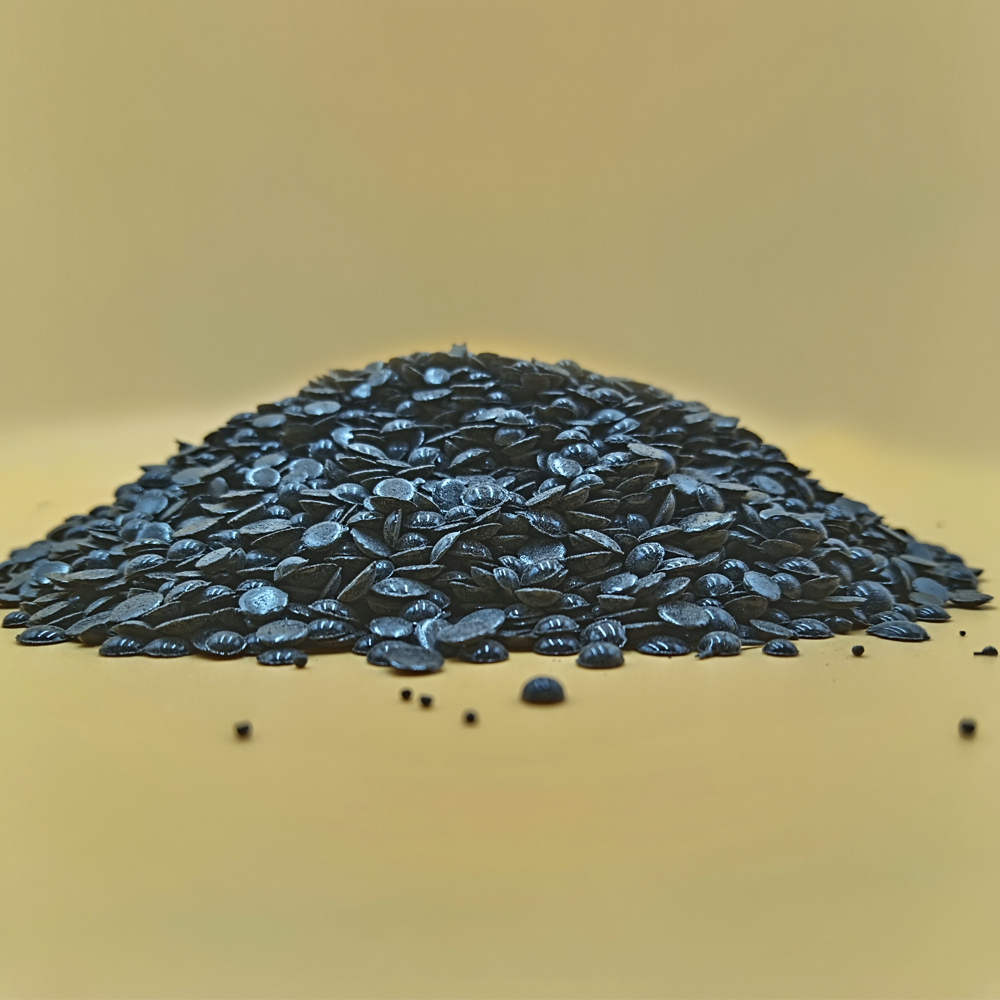

Bitumen anti-rutting additives play a crucial role in enhancing the durability and performance of streets and highways. These additives are specifically designed to prevent rutting, which is a common issue in asphalt pavements caused by repeated traffic loading. By incorporating rutting inhibitor modifiers into the bitumen mix, engineers and contractors can significantly improve the overall quality and longevity of road surfaces.

One of the key benefits of using bitumen anti-rutting additives is the increased resistance to deformation. Rutting occurs when the asphalt pavement becomes soft and deforms under the weight of passing vehicles. This can Lead to uneven surfaces, reduced skid resistance, and ultimately, the need for costly repairs. By adding rutting inhibitor modifiers to the bitumen mix, the pavement becomes more resistant to deformation, resulting in a smoother and more durable road surface.

In addition to preventing rutting, bitumen anti-rutting additives also help improve the fatigue resistance of the pavement. Fatigue cracking is another common issue in asphalt pavements, especially in areas with high traffic volumes. These cracks can compromise the structural integrity of the pavement and lead to premature failure. By using rutting inhibitor modifiers, engineers can enhance the flexibility and elasticity of the asphalt mix, reducing the likelihood of fatigue cracking and extending the lifespan of the pavement.

Furthermore, bitumen anti-rutting additives can also improve the overall performance of the pavement in terms of skid resistance and water drainage. Rutting inhibitor modifiers help create a more stable and uniform pavement surface, which enhances the grip between tires and the road. This, in turn, improves the Safety of the road for drivers and reduces the risk of accidents. Additionally, by preventing rutting, these additives also help maintain proper water drainage on the pavement, reducing the likelihood of standing water and hydroplaning.

Another advantage of using bitumen anti-rutting additives is the cost-effectiveness of road maintenance. By incorporating rutting inhibitor modifiers into the bitumen mix during construction, engineers can reduce the need for frequent repairs and maintenance activities. This not only saves time and resources but also minimizes disruptions to traffic flow. In the long run, investing in high-quality anti-rutting additives can result in significant cost savings for municipalities and transportation agencies.

Overall, the benefits of using bitumen anti-rutting additives in street construction are clear. From preventing rutting and fatigue cracking to improving skid resistance and water drainage, these additives play a crucial role in enhancing the durability and performance of asphalt pavements. By investing in high-quality rutting inhibitor modifiers, engineers and contractors can ensure the longevity and safety of road surfaces, ultimately benefiting both drivers and taxpayers alike.

How Rutting Inhibitor Modifiers Improve Highway Durability and Longevity

Rutting on highways is a common issue that can lead to safety hazards and increased maintenance costs. Rutting occurs when the pavement surface becomes deformed and develops ruts or depressions due to repeated traffic loading. This can be particularly problematic in areas with high traffic volumes or heavy vehicles. To address this issue, rutting inhibitor modifiers are often used in the production of bitumen for streets and highways.

Rutting inhibitor modifiers are additives that are mixed with bitumen to improve its resistance to deformation under traffic loading. These modifiers help to enhance the durability and longevity of the pavement surface, reducing the need for frequent repairs and maintenance. By incorporating rutting inhibitor modifiers into the bitumen mix, highway engineers can create a more robust pavement structure that can withstand the stresses of heavy traffic.

One of the key benefits of using rutting inhibitor modifiers is their ability to increase the stiffness of the bitumen. This helps to prevent the pavement surface from becoming too soft and susceptible to deformation. By improving the stiffness of the bitumen, rutting inhibitor modifiers can help to distribute the load more evenly across the pavement surface, reducing the risk of rutting and extending the service life of the highway.

In addition to improving the stiffness of the bitumen, rutting inhibitor modifiers can also enhance its resistance to high temperatures. In hot weather conditions, the pavement surface can soften and become more prone to rutting. By incorporating rutting inhibitor modifiers into the bitumen mix, highway engineers can create a more heat-resistant pavement surface that is less likely to deform under high temperatures.

Furthermore, rutting inhibitor modifiers can help to improve the adhesion between the bitumen and the aggregate in the pavement mix. This can help to prevent the aggregate particles from becoming dislodged and migrating to the surface, which can contribute to rutting and reduce the overall durability of the pavement. By enhancing the adhesion between the bitumen and the aggregate, rutting inhibitor modifiers can help to create a more stable and long-lasting pavement structure.

Overall, rutting inhibitor modifiers play a crucial role in improving the durability and longevity of highways. By enhancing the stiffness and heat resistance of the bitumen, as well as improving the adhesion between the bitumen and the aggregate, these modifiers can help to prevent rutting and extend the service life of the pavement surface. This can result in significant cost savings for highway agencies and improve the safety and performance of the roadway for motorists.

| Nr. | Commodity Name |

| 1 | High Modulus Agent for road use |

In conclusion, rutting inhibitor modifiers are an essential component in the production of bitumen for streets and highways. By incorporating these additives into the bitumen mix, highway engineers can create a more durable and long-lasting pavement surface that is resistant to rutting. With their ability to improve the stiffness, heat resistance, and adhesion of the bitumen, rutting inhibitor modifiers are a valuable tool in the fight against pavement deformation and can help to ensure the longevity of our highway infrastructure.