Table of Contents

Benefits of Using Liquid Anti-Stripping Agent in Asphalt Adhesive Applications

Asphalt adhesive is a crucial component in the construction and maintenance of roads, highways, and other paved surfaces. It is used to bind together aggregates and create a durable, long-lasting surface that can withstand heavy traffic and harsh weather conditions. However, one of the common issues that can arise with asphalt adhesive is stripping, which occurs when the bond between the asphalt and the aggregates is weakened or broken, leading to premature deterioration of the pavement.

| Nr. | Product |

| 1 | Lignin Fiber |

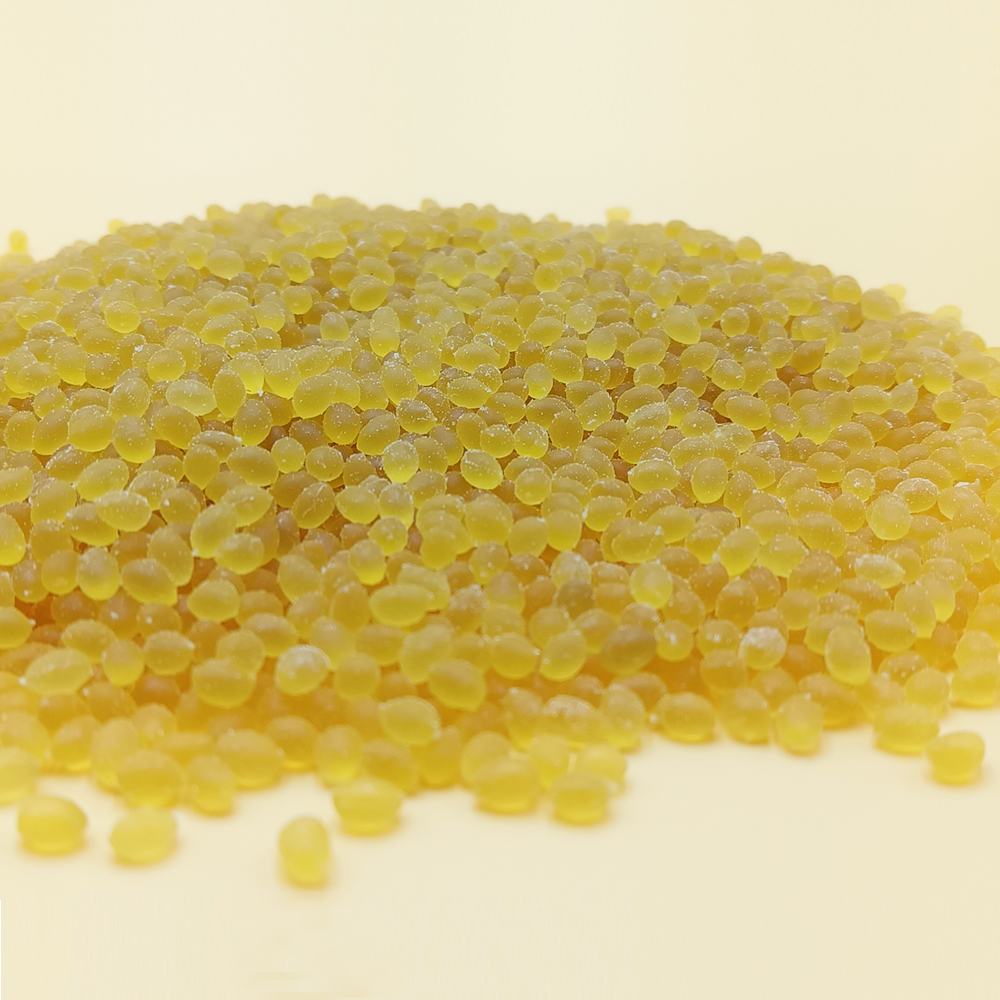

To combat this problem, liquid anti-stripping agents have been developed to improve the adhesion between the asphalt and the aggregates, ensuring a stronger and more durable bond. These agents work by chemically modifying the asphalt binder to enhance its adhesion properties, making it more resistant to moisture and other factors that can cause stripping. By incorporating a liquid anti-stripping agent into the asphalt adhesive mix, contractors can significantly reduce the risk of premature pavement failure and extend the lifespan of the paved surface.

| Nr. | Commodity Name |

| 1 | Viscosity enhancing Bitumen additive |

| No. | Article Name |

| 1 | Asphalt warm mix additive |

One of the key benefits of using a liquid anti-stripping agent in asphalt adhesive applications is improved durability. By enhancing the adhesion between the asphalt binder and the aggregates, these agents help create a stronger, more resilient pavement that can withstand heavy traffic loads and harsh environmental conditions. This can result in reduced maintenance costs and longer service life for the paved surface, ultimately saving time and money for contractors and road authorities.

| Nr. | Article Name |

| 1 | Liquid bonding agent Additive |

| No. | Item |

| 1 | Asphalt pavement sustainable additives |

In addition to improved durability, liquid anti-stripping agents also offer environmental benefits. By reducing the need for frequent repairs and maintenance, these agents help minimize the environmental impact of road construction and maintenance activities. This can Lead to lower carbon emissions, reduced energy consumption, and overall sustainability in the construction industry. Furthermore, by extending the lifespan of paved surfaces, liquid anti-stripping agents can help conserve natural resources and reduce the amount of waste generated from road maintenance activities.

Another advantage of using liquid anti-stripping agents in asphalt adhesive applications is improved Safety. Pavement failure due to stripping can create hazardous driving conditions, leading to accidents and injuries on the road. By enhancing the adhesion between the asphalt binder and the aggregates, these agents help create a smoother, more stable surface that offers better traction and skid resistance. This can help prevent accidents and improve overall road safety for drivers, pedestrians, and cyclists.

Overall, the benefits of using liquid anti-stripping agents in asphalt adhesive applications are clear. From improved durability and environmental sustainability to enhanced safety and cost savings, these agents offer a range of advantages for contractors, road authorities, and the general public. By incorporating liquid anti-stripping agents into asphalt adhesive mixes, construction professionals can create stronger, longer-lasting pavements that provide a smooth and safe driving experience for all road users.