Table of Contents

Benefits of Regular Maintenance for Lift Cables

Lift cables are an essential component of any Elevator system, responsible for safely Transporting passengers between floors. These cables are subjected to constant wear and tear due to the weight of the elevator car and the frequent movement up and Down the shaft. Regular maintenance of lift cables is crucial to ensure the Safety and efficiency of the elevator system.

One of the key benefits of regular maintenance for lift cables is the prevention of accidents. Lift cables that are not properly maintained can become worn or frayed, increasing the risk of a cable snapping while the elevator is in use. This can result in a dangerous situation for passengers and potentially Lead to serious injuries or even fatalities. By conducting regular inspections and maintenance on lift cables, potential issues can be identified and addressed before they escalate into a safety hazard.

In addition to preventing accidents, regular maintenance of lift cables can also help to extend the lifespan of the cables and other components of the elevator system. Lift cables that are well-maintained are less likely to experience premature wear and tear, reducing the need for costly repairs or replacements. By investing in regular maintenance for lift cables, building owners can save money in the long run by avoiding the need for major repairs or replacements.

Another benefit of regular maintenance for lift cables is improved efficiency. Lift cables that are properly maintained operate more smoothly and efficiently, resulting in faster and more reliable elevator service. This can help to improve the overall experience for passengers and reduce the likelihood of downtime due to mechanical issues. By keeping lift cables in good condition, building owners can ensure that their elevator system is operating at peak performance at all times.

Regular maintenance of lift cables also helps to comply with safety regulations and industry standards. Building codes and regulations require that elevator systems be regularly inspected and maintained to ensure the safety of passengers and building occupants. By staying up to date with maintenance schedules and inspections, building owners can demonstrate their commitment to safety and compliance with regulatory requirements.

Overall, the benefits of regular maintenance for lift cables are clear. By investing in routine inspections and maintenance, building owners can prevent accidents, extend the lifespan of their elevator system, improve efficiency, and comply with safety regulations. Regular maintenance of lift cables is a small investment that can yield significant returns in terms of safety, efficiency, and cost savings. Building owners should prioritize the maintenance of lift cables to ensure the safe and reliable operation of their elevator systems.

Common Signs of Wear and Tear in Lift Cables

Lift cables are an essential component of any elevator system, responsible for safely transporting passengers between floors. Over time, lift cables can experience wear and tear due to the constant movement and weight they bear. It is crucial for building owners and maintenance personnel to be aware of the common signs of wear and tear in lift cables to prevent accidents and ensure the smooth operation of the elevator.

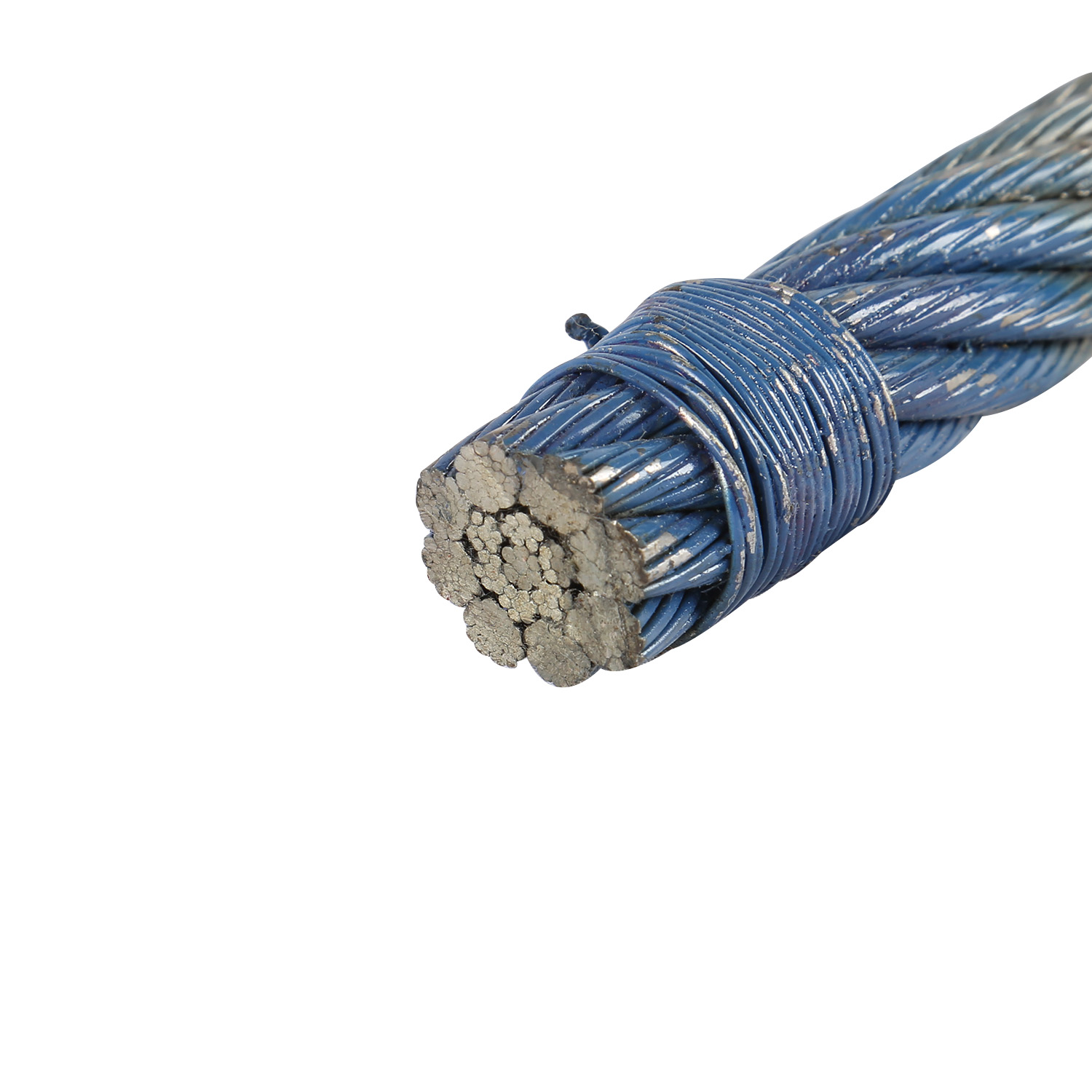

One of the most noticeable signs of wear and tear in lift cables is fraying. Fraying occurs when the individual strands of the cable start to unravel, exposing the inner core. This can weaken the overall strength of the cable and increase the risk of it snapping under the weight of the elevator. Regular inspections of lift cables should be conducted to check for any signs of fraying and address them promptly.

Another common sign of wear and tear in lift cables is corrosion. Corrosion can occur due to exposure to moisture or Chemicals in the Environment, causing the cables to weaken and become brittle. It is essential to regularly inspect lift cables for any signs of rust or corrosion and take appropriate measures to prevent further damage.

In addition to fraying and corrosion, another sign of wear and tear in lift cables is kinking. Kinking occurs when the cable is bent or twisted in an unnatural way, causing stress on the individual strands. This can weaken the overall structure of the cable and increase the risk of it breaking. Regular maintenance and inspections can help identify any kinks in lift cables and address them before they become a safety hazard.

Furthermore, another common sign of wear and tear in lift cables is stretching. Over time, lift cables can stretch due to the constant weight and movement of the elevator. This can lead to uneven tension in the cables, causing them to wear out faster and potentially snap. Regular tension tests should be conducted to ensure that lift cables are within the recommended limits and replace them if necessary.

It is essential for building owners and maintenance personnel to be proactive in identifying and addressing signs of wear and tear in lift cables to prevent accidents and ensure the safety of passengers. Regular inspections, maintenance, and testing can help prolong the lifespan of lift cables and prevent costly repairs or replacements in the future.

In conclusion, lift cables are a critical component of any elevator system, and it is essential to be aware of the common signs of wear and tear in these cables. Fraying, corrosion, kinking, stretching are all Indicators that lift cables may need to be replaced or repaired. Regular inspections and maintenance can help prevent accidents and ensure the smooth operation of the elevator. By staying vigilant and addressing signs of wear and tear promptly, building owners can ensure the safety of passengers and the longevity of their elevator system.