Table of Contents

Benefits of Using Large Diameter Galvanized Square Pipe for Industrial Applications

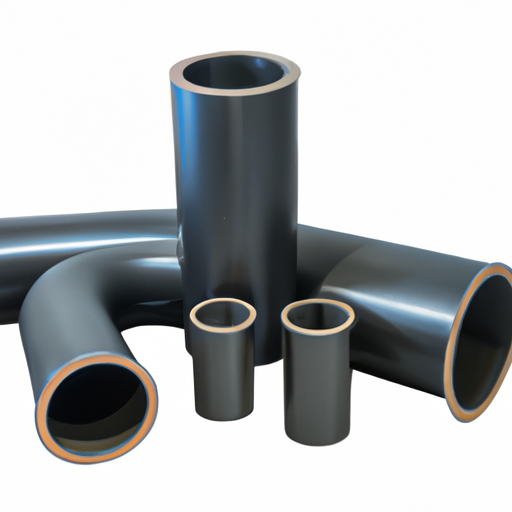

Large diameter galvanized square pipes, such as the 32mm galvanized steel pipe, are widely used in various industrial applications due to their numerous benefits. These pipes are known for their durability, strength, and corrosion resistance, making them ideal for a wide range of applications in industries such as construction, manufacturing, and Agriculture.

One of the key benefits of using large diameter galvanized square pipes is their superior corrosion resistance. The galvanization process involves coating the steel pipe with a layer of Zinc, which helps protect the underlying steel from rust and corrosion. This makes galvanized pipes ideal for outdoor applications where they may be exposed to harsh weather conditions or corrosive substances.

In addition to their corrosion resistance, large diameter galvanized square pipes are also known for their strength and durability. The galvanization process not only protects the steel from corrosion but also adds an extra layer of protection that helps prevent damage from impact or heavy loads. This makes galvanized pipes a reliable choice for structural applications where strength and durability are essential.

Furthermore, large diameter galvanized square pipes are easy to install and require minimal maintenance. The galvanized coating helps extend the lifespan of the pipe, reducing the need for frequent repairs or replacements. This can result in cost savings for industrial applications that require long-lasting and reliable piping solutions.

Another benefit of using large diameter galvanized square pipes is their versatility. These pipes can be easily customized to meet specific requirements, such as different lengths, diameters, or thicknesses. This flexibility makes galvanized pipes suitable for a wide range of applications, from water distribution systems to structural support in buildings.

Moreover, large diameter galvanized square pipes are environmentally friendly. The galvanization process does not involve any harmful Chemicals or pollutants, making it a sustainable choice for industrial applications. Additionally, the long lifespan of galvanized pipes means that they can be reused or recycled at the end of their service life, further reducing their environmental impact.

In conclusion, large diameter galvanized square pipes offer a wide range of benefits for industrial applications. From their superior corrosion resistance and strength to their ease of installation and versatility, galvanized pipes are a reliable and cost-effective choice for a variety of industries. With their durability, low maintenance requirements, and environmental sustainability, galvanized pipes are a smart investment for any industrial application that requires reliable and long-lasting piping solutions.

How to Properly Install and Maintain 32mm Galvanized Steel Pipe for Longevity

Galvanized Steel Pipes are a popular choice for various construction projects due to their durability and resistance to corrosion. Among the different sizes available, the 32mm galvanized steel pipe is commonly used for applications that require a larger diameter. Proper installation and maintenance of these pipes are crucial to ensure their longevity and optimal performance.

When installing a 32mm galvanized steel pipe, it is essential to follow a few key steps to ensure a secure and reliable connection. First and foremost, it is important to properly measure and cut the pipe to the desired length using a pipe cutter or hacksaw. It is crucial to ensure that the cut is clean and straight to prevent any leaks or weak points in the pipe.

Once the pipe is cut to size, the next step is to prepare the ends for fitting. This involves removing any burrs or rough edges using a file or sandpaper to ensure a smooth and even surface. It is also important to clean the ends of the pipe with a degreaser or solvent to remove any dirt, grease, or debris that could interfere with the fitting process.

After preparing the ends of the pipe, the next step is to connect the pipe to the fittings using the appropriate method. This may involve using threaded fittings, compression fittings, or soldering depending on the specific requirements of the project. It is important to follow the manufacturer’s instructions and guidelines for the specific type of fitting being used to ensure a secure and leak-free connection.

Once the pipe is properly installed, it is important to regularly inspect and maintain it to ensure its longevity and optimal performance. This includes checking for any signs of corrosion, leaks, or damage and addressing any issues promptly to prevent further damage or deterioration.

One of the most common maintenance tasks for galvanized steel pipes is to periodically inspect and clean the pipe to remove any buildup of rust, scale, or debris. This can be done using a wire brush, sandpaper, or a chemical cleaner to remove any corrosion or buildup that could compromise the integrity of the pipe.

In addition to regular cleaning, it is also important to inspect the pipe for any signs of leaks or damage. This may involve checking for any visible signs of corrosion, rust, or discoloration on the surface of the pipe, as well as checking for any leaks or drips around the fittings.

https://www.youtube.com/watch?v=2Bv9gBwsv20

If any issues are identified during the inspection process, it is important to address them promptly to prevent further damage or deterioration. This may involve repairing or replacing damaged sections of the pipe, tightening loose fittings, or applying a protective coating to prevent corrosion.

In conclusion, proper installation and maintenance of a 32mm galvanized steel pipe are essential to ensure its longevity and optimal performance. By following the steps outlined above and regularly inspecting and maintaining the pipe, you can ensure that it will continue to serve its intended purpose for many years to come.