Table of Contents

Benefits of Using Bituminous Warm Mixing Compound in Asian High Grade Manufacturing Plants

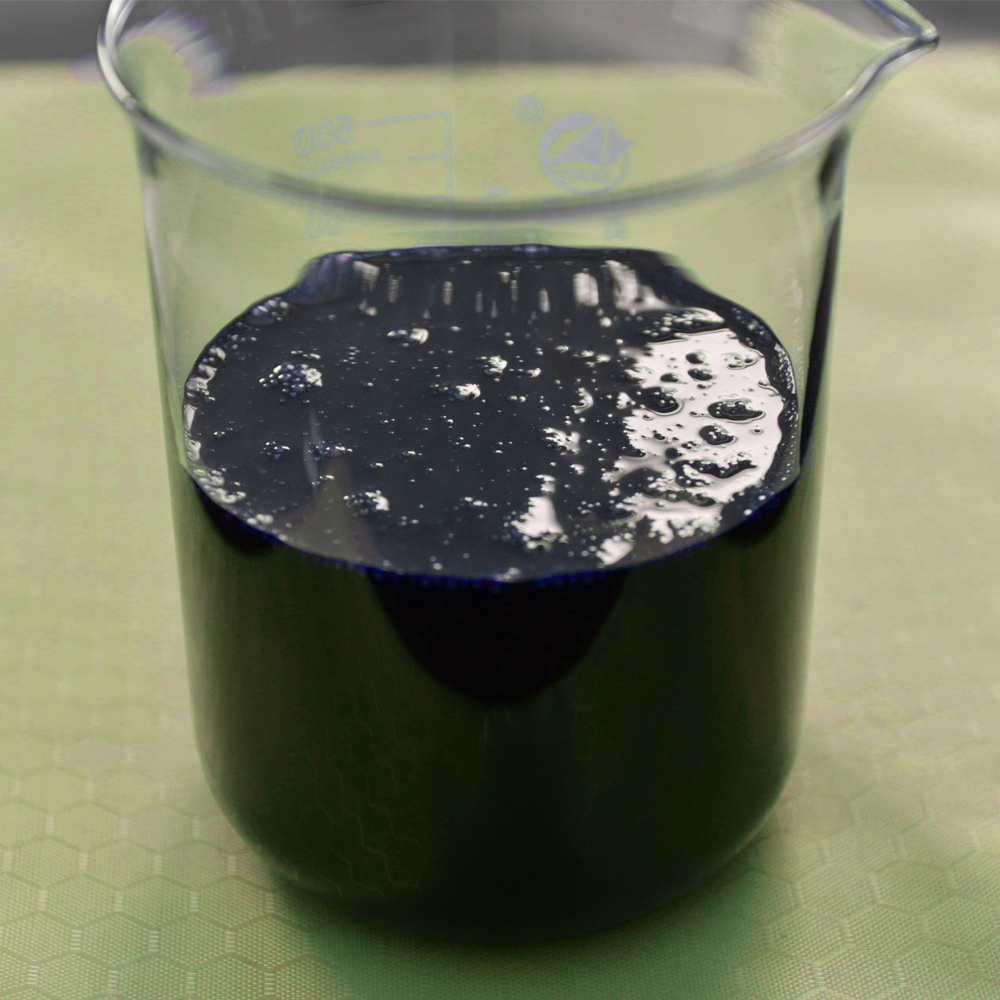

Bituminous warm mixing compound has become increasingly popular in Asian high-grade manufacturing plants due to its numerous benefits. This innovative technology offers a more sustainable and cost-effective alternative to traditional hot mix asphalt, making it an attractive option for companies looking to improve their operations.

One of the key advantages of using bituminous warm mixing compound is its lower production temperatures. Unlike hot mix asphalt, which requires high temperatures to be produced, warm mix asphalt can be manufactured at lower temperatures. This not only reduces energy consumption but also lowers greenhouse gas emissions, making it a more environmentally friendly option for manufacturing plants.

In addition to its environmental benefits, bituminous warm mixing compound offers improved workability and compaction compared to hot mix asphalt. The lower production temperatures allow for better mixing and coating of aggregates, resulting in a more uniform and durable pavement. This can Lead to reduced maintenance costs and longer-lasting roads, ultimately saving manufacturing plants time and money in the long run.

Furthermore, the use of bituminous warm mixing compound can help manufacturing plants meet regulatory requirements and sustainability goals. Many Asian countries have strict regulations regarding emissions and environmental impact, and warm mix asphalt can help companies comply with these regulations while still producing high-quality pavement. By using this technology, manufacturing plants can demonstrate their commitment to sustainability and responsible business practices.

Another benefit of bituminous warm mixing compound is its versatility. This technology can be used in a wide range of applications, from highways and roads to parking lots and driveways. This flexibility allows manufacturing plants to tailor their pavement solutions to meet specific project requirements, ensuring optimal performance and durability.

Moreover, bituminous warm mixing compound offers improved Safety benefits for manufacturing plants. The lower production temperatures reduce the risk of worker exposure to hot asphalt fumes and burns, creating a safer working Environment for employees. Additionally, the enhanced workability and compaction of warm mix asphalt can lead to smoother and more skid-resistant pavement, reducing the risk of accidents and injuries on the road.

Overall, the benefits of using bituminous warm mixing compound in Asian high-grade manufacturing plants are clear. From its environmental advantages to its improved workability and safety benefits, this technology offers a sustainable and cost-effective solution for companies looking to enhance their pavement operations. By incorporating warm mix asphalt into their production processes, manufacturing plants can achieve higher quality pavement, lower maintenance costs, and greater overall efficiency. As the demand for sustainable and innovative pavement solutions continues to grow, bituminous warm mixing compound is poised to become a key technology in the Asian manufacturing industry.

How to Optimize Production Efficiency in Bituminous Warm Mixing Compound Manufacturing Plants in Asia

Bituminous warm mixing compound is a crucial material used in the construction of roads and highways. With the increasing demand for infrastructure development in Asia, the need for efficient manufacturing plants producing high-quality bituminous warm mixing compound has never been greater. In order to meet this demand, it is essential for manufacturing plants to optimize their production efficiency.

One of the key factors in optimizing production efficiency in bituminous warm mixing compound manufacturing plants is the use of high-grade equipment and technology. Investing in state-of-the-art machinery and tools can significantly improve the quality and output of the final product. By using advanced technology, plants can ensure a more consistent mix of materials, resulting in a higher-quality end product.

In addition to using high-grade equipment, it is also important for manufacturing plants to implement efficient production processes. This includes streamlining workflows, minimizing downtime, and reducing waste. By carefully planning and organizing production processes, plants can maximize their output while minimizing costs.

Another important aspect of optimizing production efficiency is the training and development of plant personnel. Well-trained and skilled employees are essential for ensuring smooth operations and high-quality output. By investing in training programs and continuous education for employees, manufacturing plants can improve overall efficiency and productivity.

| Number | Products |

| 1 | Warm Mixing asphalt improvement agents |

Furthermore, it is crucial for manufacturing plants to regularly monitor and analyze their production processes. By collecting and analyzing data on key performance Indicators, plants can identify areas for improvement and implement strategies to increase efficiency. This may include adjusting production schedules, optimizing material usage, or implementing new technologies.

Collaboration with suppliers and partners is also essential for optimizing production efficiency in bituminous warm mixing compound manufacturing plants. By working closely with suppliers to ensure a steady supply of high-quality materials, plants can avoid disruptions in production and maintain consistent output. Additionally, partnering with other industry players can provide access to new technologies and best practices, further enhancing efficiency.

To further optimize production efficiency, manufacturing plants should also focus on sustainability and environmental responsibility. By implementing eco-friendly practices, such as Recycling waste materials and reducing energy consumption, plants can not only reduce their environmental impact but also improve overall efficiency. Sustainable practices can also help plants comply with regulations and attract environmentally conscious customers.

In conclusion, optimizing production efficiency in bituminous warm mixing compound manufacturing plants in Asia requires a holistic approach that encompasses technology, processes, personnel, collaboration, and sustainability. By investing in high-grade equipment, implementing efficient processes, training employees, monitoring performance, collaborating with partners, and focusing on sustainability, plants can achieve higher productivity, lower costs, and better quality output. With the growing demand for infrastructure development in Asia, optimizing production efficiency is essential for the success and competitiveness of manufacturing plants in the region.