Table of Contents

Benefits of Using Thermal Asphalt Blend Additives

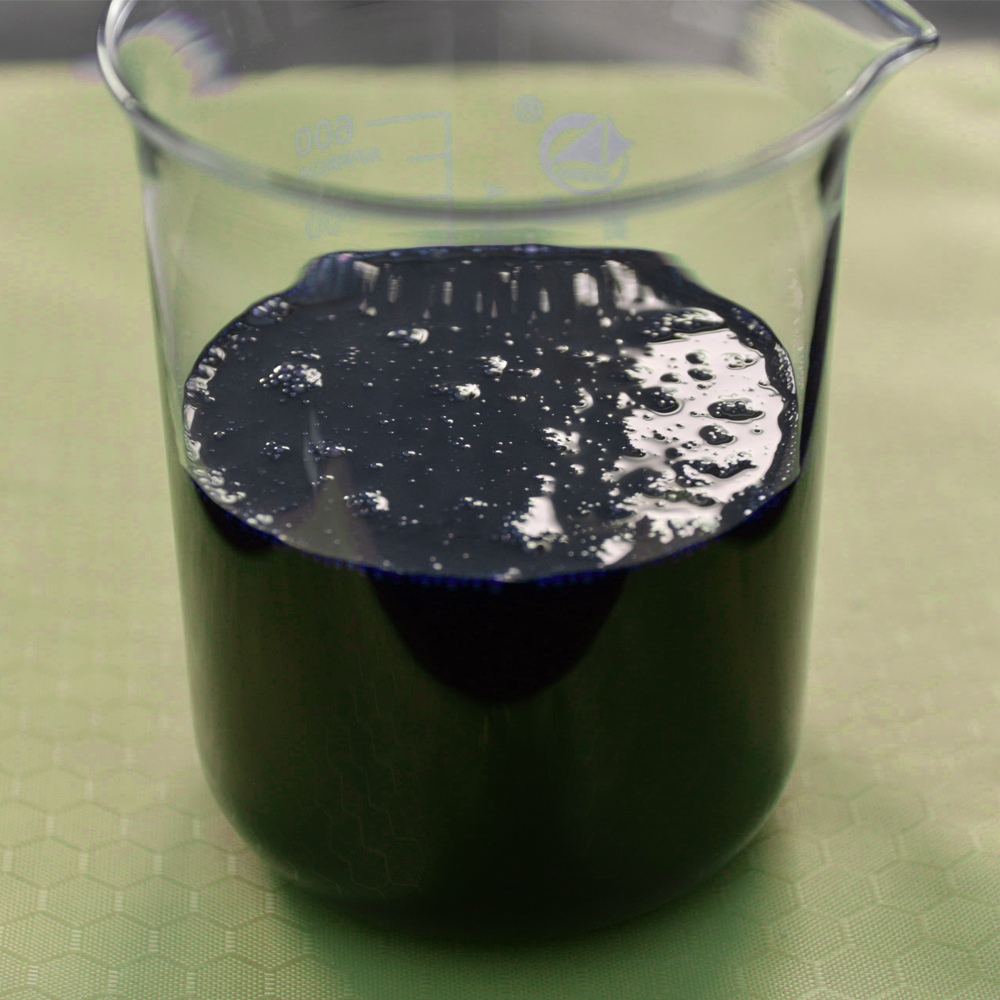

Thermal asphalt blend additives, also known as warm mix asphalt additives, are a type of material that is added to asphalt mixtures to lower the temperature at which the asphalt can be mixed and compacted. This process offers several benefits over traditional hot mix asphalt, including reduced energy consumption, lower emissions, and improved workability.

One of the key benefits of using thermal asphalt blend additives is the reduction in energy consumption during the production and placement of the asphalt mixture. By lowering the temperature at which the asphalt can be mixed and compacted, less energy is required to heat the materials to the necessary temperature. This can result in significant cost savings for asphalt producers, as well as a reduction in greenhouse gas emissions associated with the production process.

| No. | Article Name |

| 1 | warm mix agents |

In addition to reducing energy consumption, thermal asphalt blend additives also help to lower emissions during the production and placement of the asphalt mixture. By reducing the temperature at which the asphalt can be mixed and compacted, less fuel is required to heat the materials, resulting in lower emissions of harmful pollutants such as carbon monoxide and nitrogen oxides. This can help to improve air quality in the surrounding area and reduce the environmental impact of asphalt production.

Another benefit of using thermal asphalt blend additives is the improved workability of the asphalt mixture. By lowering the temperature at which the asphalt can be mixed and compacted, the materials are easier to handle and manipulate, resulting in a smoother and more uniform finished product. This can help to reduce the occurrence of defects such as segregation and rutting, resulting in a longer-lasting and more durable pavement surface.

Overall, the use of thermal asphalt blend additives offers several benefits over traditional hot mix asphalt, including reduced energy consumption, lower emissions, and improved workability. By lowering the temperature at which the asphalt can be mixed and compacted, these additives help to make the production process more efficient and environmentally friendly. Additionally, the improved workability of the asphalt mixture can result in a higher quality finished product that is more resistant to wear and tear.

In conclusion, thermal asphalt blend additives are a valuable tool for asphalt producers looking to reduce energy consumption, lower emissions, and improve the workability of their asphalt mixtures. By incorporating these additives into their production process, producers can enjoy a range of benefits that can help to improve the overall quality and sustainability of their asphalt pavements. Whether you are a contractor looking to reduce costs and improve efficiency, or a government agency looking to reduce emissions and improve air quality, thermal asphalt blend additives are a smart choice for your next asphalt project.