Table of Contents

Benefits of Using Polyester Fiber for Pavement in Highway Construction

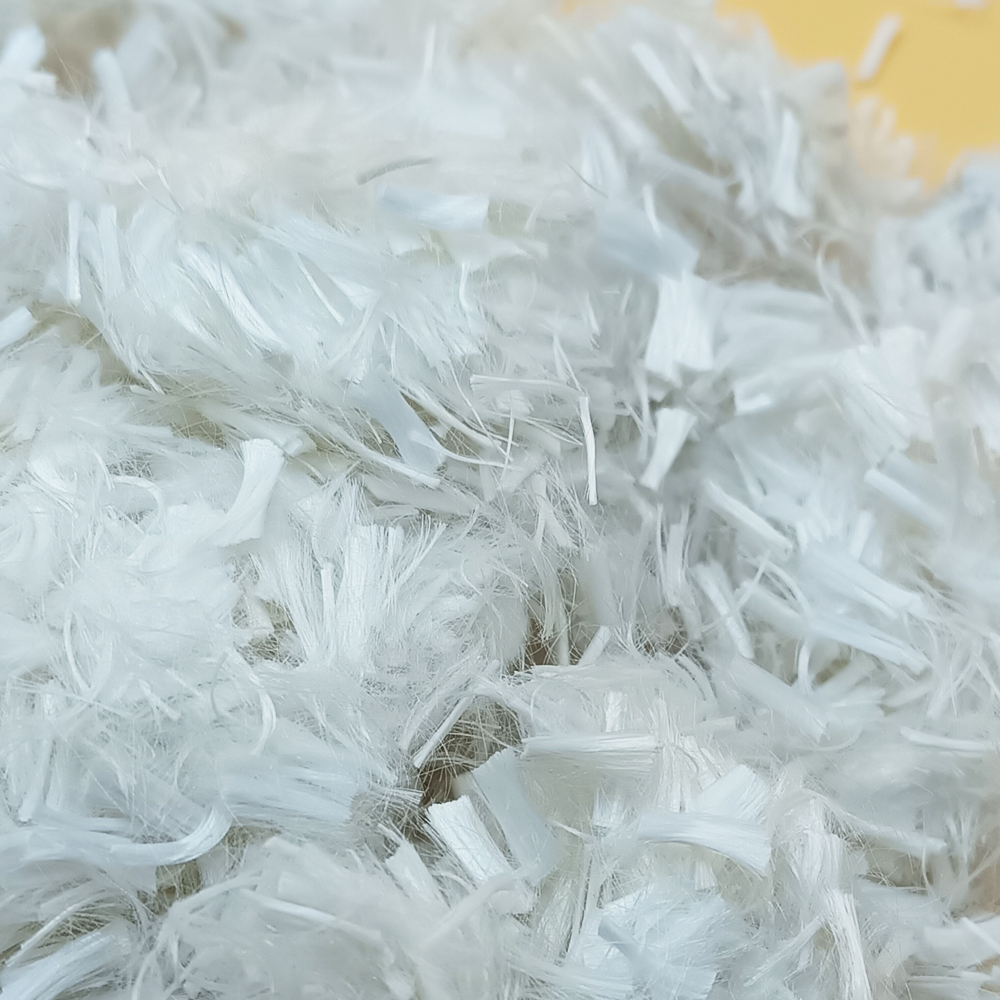

Polyester fiber is a versatile material that has found its way into various industries, including the construction of highways. This synthetic fiber is known for its strength, durability, and resistance to wear and tear, making it an ideal choice for reinforcing pavement in highway construction. In this article, we will explore the benefits of using polyester fiber for pavement in highway construction.

One of the key advantages of using polyester fiber in pavement construction is its ability to prevent cracking. Cracks in pavement can Lead to a host of issues, including water infiltration, potholes, and overall deterioration of the road surface. By adding polyester fiber to the pavement mix, engineers can significantly reduce the likelihood of cracking, thereby extending the lifespan of the road and reducing maintenance costs.

In addition to preventing cracking, polyester fiber also helps to improve the overall strength and durability of the pavement. This is particularly important in high-traffic areas where the road surface is subjected to heavy loads and constant wear and tear. The addition of polyester fiber helps to distribute the load more evenly across the pavement, reducing the risk of rutting and other forms of damage.

Furthermore, polyester fiber is resistant to moisture and Chemicals, making it an ideal choice for pavement construction in areas that are prone to harsh weather conditions or exposure to corrosive substances. This resistance to moisture and chemicals helps to maintain the integrity of the pavement over time, ensuring that it remains safe and functional for years to come.

Another benefit of using polyester fiber in pavement construction is its ease of installation. Unlike traditional reinforcement methods, such as steel mesh or rebar, polyester fiber can be easily mixed into the pavement mix without the need for specialized equipment or additional labor. This not only saves time and money during the construction process but also ensures a more uniform distribution of the fiber throughout the pavement.

Moreover, polyester fiber is a sustainable and environmentally friendly option for pavement construction. Unlike traditional reinforcement materials, such as steel, polyester fiber is made from recycled materials and can be recycled at the end of its lifespan. This helps to reduce the environmental impact of highway construction and promotes a more sustainable approach to infrastructure development.

In conclusion, the benefits of using polyester fiber for pavement in highway construction are clear. From preventing cracking and improving strength to resisting moisture and chemicals, polyester fiber offers a range of advantages that make it an ideal choice for reinforcing pavement in high-traffic areas. Its ease of installation and sustainability further add to its appeal as a cost-effective and environmentally friendly option for road construction. By incorporating polyester fiber into pavement projects, engineers can create safer, more durable roads that will stand the test of time.

How Polyester Fiber Enhances Road Security and Prevents Cracks in Pavement

Polyester fiber is a versatile material that has found its way into various industries, including the construction and infrastructure sector. One of the key applications of polyester fiber is in enhancing road security and preventing cracks in pavement. This innovative use of polyester fiber has revolutionized the way roads are built and maintained, leading to safer and more durable infrastructure.

One of the main benefits of using polyester fiber in pavement is its ability to improve the overall strength and durability of the road surface. By adding polyester fiber to the asphalt mix, engineers can create a more robust pavement that is better able to withstand heavy traffic loads and harsh weather conditions. This, in turn, helps to prevent cracks from forming in the pavement, which can compromise the structural integrity of the road and pose a Safety hazard to motorists.

In addition to enhancing the strength of the pavement, polyester fiber also helps to improve the flexibility and fatigue resistance of the road surface. This means that the pavement is better able to absorb the stresses and strains that are placed on it, such as the weight of passing vehicles and changes in temperature. As a result, the road is less likely to develop cracks and other forms of damage, which can lead to costly repairs and maintenance in the long run.

Furthermore, polyester fiber can also help to reduce the occurrence of reflective cracking in pavement. Reflective cracking occurs when cracks in the underlying layers of the road surface propagate up through the asphalt layer, causing visible cracks on the surface of the road. By adding polyester fiber to the asphalt mix, engineers can create a barrier that helps to prevent these cracks from reaching the surface, thereby extending the lifespan of the pavement and reducing the need for frequent repairs.

| Nr. | Item |

| 1 | Artificial fibers for Road maintenance |

Another key advantage of using polyester fiber in pavement is its ability to improve the skid resistance of the road surface. Skid resistance is an important factor in road safety, as it helps to prevent vehicles from skidding or sliding out of control, especially in wet or icy conditions. By incorporating polyester fiber into the asphalt mix, engineers can create a pavement that offers better traction and grip, reducing the risk of accidents and improving overall road security.

In conclusion, polyester fiber is a valuable material that can greatly enhance road security and prevent cracks in pavement. By improving the strength, flexibility, fatigue resistance, and skid resistance of the road surface, polyester fiber helps to create safer and more durable infrastructure that can withstand the rigors of daily use. As technology continues to advance, we can expect to see even more innovative uses of polyester fiber in the construction and maintenance of roads, further improving the safety and reliability of our transportation networks.