Table of Contents

Benefits of Using Hot Rolled Seamless Alloy Round Steel Tube 1527 Gr. 1330 1020 1045 1040 Alloy Structural Steel Pipe

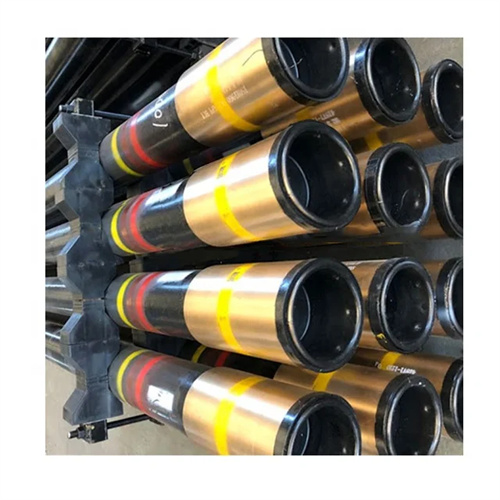

Hot rolled seamless alloy round steel tubes are a popular choice in various industries due to their durability, strength, and versatility. These tubes are made from high-quality Alloy Steel, such as 1527, Gr. 1330, 1020, 1045, and 1040, which are known for their excellent mechanical properties. In this article, we will discuss the benefits of using hot rolled seamless alloy round steel tubes in different applications.

One of the main advantages of hot rolled seamless alloy round steel tubes is their superior strength. These tubes are able to withstand high pressure and heavy loads, making them ideal for use in structural applications. Whether it is for building construction, machinery manufacturing, or automotive components, hot rolled seamless alloy round steel tubes provide the necessary strength and support to ensure the structural integrity of the final product.

In addition to their strength, hot rolled seamless alloy round steel tubes also offer excellent corrosion resistance. The alloy steel used in these tubes contains elements such as chromium, Nickel, and Molybdenum, which help prevent rust and corrosion, even in harsh environments. This makes hot rolled seamless alloy round steel tubes a reliable choice for outdoor applications or in industries where exposure to moisture or Chemicals is common.

Furthermore, hot rolled seamless alloy round steel tubes are known for their uniformity and consistency in terms of dimensions and mechanical properties. The hot rolling process ensures that the tubes have a smooth surface finish and precise dimensions, making them easy to work with and suitable for various fabrication processes. Whether it is cutting, welding, bending, or Machining, hot rolled seamless alloy round steel tubes can be easily manipulated to meet specific requirements.

Another benefit of using hot rolled seamless alloy round steel tubes is their cost-effectiveness. While alloy steel may be more expensive than Carbon Steel, the superior properties of alloy steel, such as increased strength and corrosion resistance, can result in long-term cost savings. By using hot rolled seamless alloy round steel tubes, manufacturers can reduce maintenance and replacement costs, as well as improve the overall performance and longevity of their products.

Moreover, hot rolled seamless alloy round steel tubes are also environmentally friendly. The production process of these tubes involves minimal waste and energy consumption, making them a sustainable choice for environmentally conscious industries. Additionally, the durability and recyclability of alloy steel make hot rolled seamless alloy round steel tubes a sustainable option for reducing carbon footprint and promoting eco-friendly practices.

In conclusion, hot rolled seamless alloy round steel tubes offer a wide range of benefits for various industries. From their superior strength and corrosion resistance to their cost-effectiveness and environmental sustainability, these tubes are a reliable choice for structural applications. Whether it is for building construction, machinery manufacturing, or automotive components, hot rolled seamless alloy round steel tubes provide the necessary properties to ensure the quality and performance of the final product.

Applications of Hot Rolled Seamless Alloy Round Steel Tube 1527 Gr. 1330 1020 1045 1040 Alloy Structural Steel Pipe

Hot rolled seamless alloy round steel tubes are a popular choice in various industries due to their durability, strength, and versatility. These tubes are made from high-quality alloy structural steel, such as 1527, Gr. 1330, 1020, 1045, and 1040, which are known for their excellent mechanical properties. In this article, we will explore the applications of hot rolled seamless alloy round steel tubes in different industries.

One of the primary applications of hot rolled seamless alloy round steel tubes is in the construction industry. These tubes are used in the construction of buildings, bridges, and other structures due to their high strength and resistance to corrosion. The seamless design of these tubes ensures a smooth surface finish, making them ideal for structural applications where aesthetics are important.

In the automotive industry, hot rolled seamless alloy round steel tubes are used in the manufacturing of various components, such as chassis, suspension systems, and exhaust systems. The high strength and durability of these tubes make them suitable for withstanding the harsh conditions of the road, ensuring the Safety and reliability of vehicles.

Another important application of hot rolled seamless alloy round steel tubes is in the oil and gas industry. These tubes are used in the exploration, production, and transportation of oil and gas due to their ability to withstand high pressure and temperature conditions. The seamless design of these tubes ensures leak-proof connections, making them essential for the safe and efficient operation of oil and gas pipelines.

In the aerospace industry, hot rolled seamless alloy round steel tubes are used in the manufacturing of Aircraft components, such as landing gear, Engine Mounts, and structural frames. The high strength-to-weight ratio of these tubes makes them ideal for reducing the overall weight of aircraft, improving fuel efficiency and performance.

Hot rolled seamless alloy round steel tubes are also used in the manufacturing of machinery and equipment in various industries, such as mining, Agriculture, and manufacturing. These tubes are used in the construction of heavy-duty equipment, such as cranes, Excavators, and agricultural machinery, due to their ability to withstand heavy loads and harsh operating conditions.

In the Renewable Energy sector, hot rolled seamless alloy round steel tubes are used in the manufacturing of wind turbines, Solar Panels, and hydroelectric power plants. These tubes are essential for the construction of renewable energy infrastructure, ensuring the efficient generation and distribution of clean energy.

In conclusion, hot rolled seamless alloy round steel tubes are versatile and essential components in various industries due to their high strength, durability, and resistance to corrosion. From construction and automotive to oil and gas, aerospace, machinery, and renewable energy, these tubes play a crucial role in ensuring the safety, reliability, and efficiency of various applications. With their superior mechanical properties and seamless design, hot rolled seamless alloy round steel tubes are a preferred choice for engineers and manufacturers looking for high-quality structural Steel Pipes.

Comparison of Hot Rolled Seamless Alloy Round Steel Tube 1527 Gr. 1330 1020 1045 1040 Alloy Structural Steel Pipe with other Steel Pipe Options

Hot rolled seamless alloy round steel tubes are a popular choice in various industries due to their durability, strength, and versatility. Among the different grades available in the market, 1527, Gr. 1330, 1020, 1045, and 1040 are some of the most commonly used alloy structural steel pipes. These grades offer unique properties that make them suitable for different applications.

When comparing hot rolled seamless alloy round steel tubes with other steel pipe options, it is essential to consider factors such as strength, corrosion resistance, weldability, and cost. Each grade of steel pipe has its advantages and disadvantages, which can influence the decision-making process for selecting the right material for a specific project.

One of the key advantages of hot rolled seamless alloy round steel tubes is their high strength-to-weight ratio. These tubes are known for their excellent mechanical properties, making them ideal for applications that require high tensile strength and toughness. The 1527 grade, for example, is a low-alloy steel that offers good weldability and machinability, making it suitable for structural components in machinery and equipment.

Gr. 1330 is another popular grade of hot rolled seamless alloy round steel tube known for its high strength and wear resistance. This grade is often used in the manufacturing of gears, Shafts, and other components that require high hardness and durability. Additionally, Gr. 1330 offers good machinability and weldability, making it a versatile choice for various industrial applications.

https://www.youtube.com/watch?v=LIFpq7-uT1g

1020 steel is a low-carbon alloy that is commonly used in the construction industry for its excellent weldability and formability. This grade of steel pipe is often used in structural applications where high strength is not a primary requirement. 1020 steel tubes are cost-effective and easy to work with, making them a popular choice for projects with budget constraints.

1045 steel is a medium-carbon alloy known for its high tensile strength and hardness. This grade of steel pipe is commonly used in the manufacturing of Hydraulic Cylinders, shafts, and other components that require high strength and wear resistance. 1045 steel tubes are also known for their excellent machinability and weldability, making them a preferred choice for applications that require precision machining.

1040 steel is another medium-carbon alloy that offers good strength and toughness. This grade of steel pipe is often used in the construction of bridges, buildings, and other structures that require high tensile strength and impact resistance. 1040 steel tubes are known for their excellent weldability and formability, making them a versatile choice for a wide range of applications.

In conclusion, hot rolled seamless alloy round steel tubes offer a range of benefits compared to other steel pipe options. Each grade of steel pipe has its unique properties that make it suitable for specific applications. When selecting the right material for a project, it is essential to consider factors such as strength, corrosion resistance, weldability, and cost. By understanding the properties of different grades of steel pipe, engineers and designers can make informed decisions to ensure the success of their projects.