Table of Contents

Benefits of Using Polypropylene Fiber in Transportation Infrastructure for Anti-Crack Roads and Improved Traffic Flow

Transportation infrastructure plays a crucial role in the development and growth of a country. Roads are the lifeline of any nation, connecting people, goods, and services. However, with the increasing traffic volume and changing weather conditions, roads are prone to cracks and damage, leading to Safety hazards and increased maintenance costs. To address these challenges, the use of polypropylene fiber in transportation infrastructure has gained popularity for its anti-crack properties and ability to improve traffic flow.

| Part | Name |

| 1 | for roadways anti Crack Fiber |

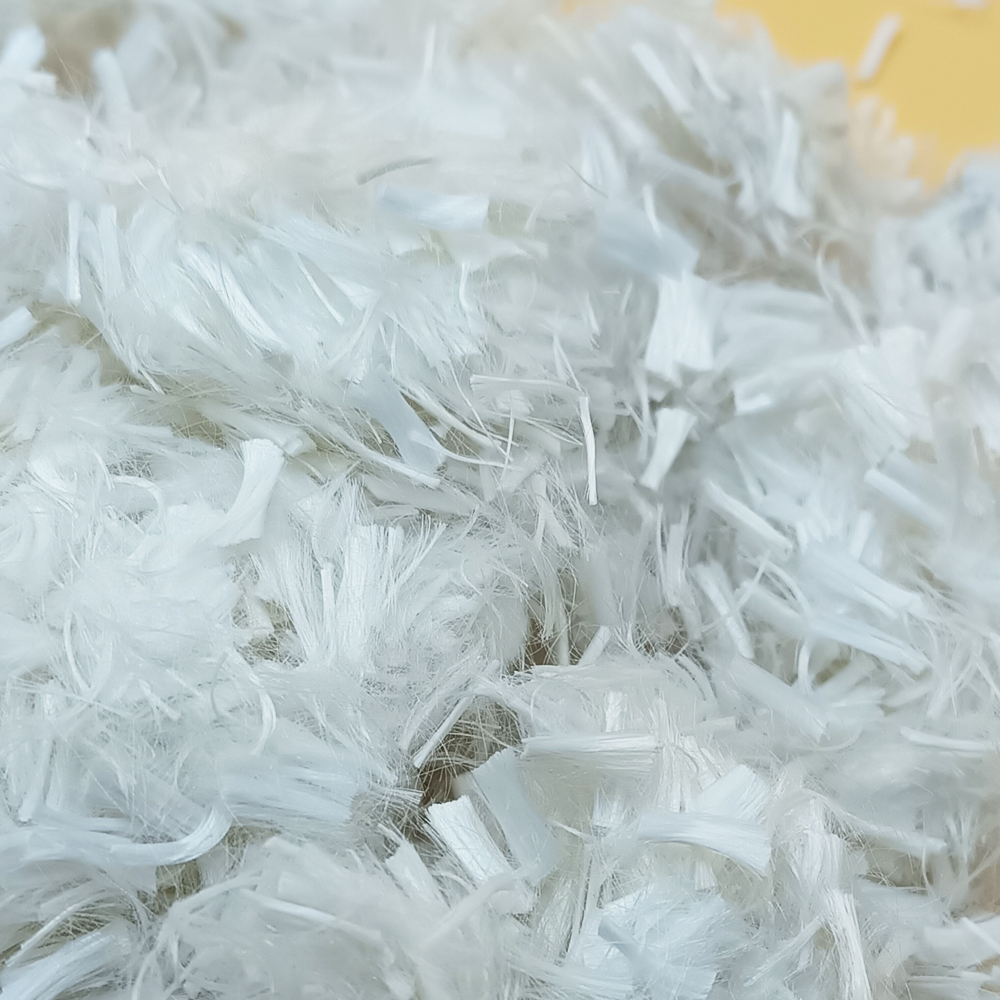

Polypropylene fiber is a synthetic material that is added to concrete and asphalt mixtures to enhance their strength and durability. When used in road construction, polypropylene fiber helps to reduce cracking caused by temperature fluctuations, heavy traffic loads, and other external factors. The fibers act as a reinforcement, providing additional support to the road surface and preventing the formation of cracks.

One of the key benefits of using polypropylene fiber in transportation infrastructure is its ability to extend the lifespan of roads. By reducing the occurrence of cracks and damage, roads constructed with polypropylene fiber require less frequent repairs and maintenance, saving time and money for transportation authorities. This not only improves the overall quality of the road network but also enhances the safety of motorists and pedestrians.

In addition to its anti-crack properties, polypropylene fiber also helps to improve traffic flow on roads. Cracks and potholes can disrupt the smooth movement of vehicles, causing congestion and delays. By using polypropylene fiber in road construction, transportation authorities can create a smoother and more durable road surface that allows for faster and more efficient traffic flow. This not only benefits commuters but also reduces fuel consumption and emissions, contributing to a more sustainable transportation system.

Furthermore, polypropylene fiber is a cost-effective solution for enhancing the performance of transportation infrastructure. Compared to traditional methods of road construction, the use of polypropylene fiber requires less material and labor, resulting in lower overall costs. Additionally, the extended lifespan of roads constructed with polypropylene fiber means that maintenance and repair expenses are reduced in the long run, providing a significant return on investment for transportation authorities.

Another advantage of using polypropylene fiber in transportation infrastructure is its versatility. The fibers can be easily incorporated into various types of road surfaces, including highways, bridges, and urban streets. This flexibility allows transportation authorities to tailor their road construction projects to meet specific requirements and challenges, ensuring the long-term durability and performance of the infrastructure.

In conclusion, the use of polypropylene fiber in transportation infrastructure offers numerous benefits for anti-crack roads and improved traffic flow. By enhancing the strength and durability of road surfaces, polypropylene fiber helps to reduce cracking, extend the lifespan of roads, and improve traffic efficiency. With its cost-effectiveness and versatility, polypropylene fiber is a valuable tool for transportation authorities looking to enhance the quality and sustainability of their road networks. By incorporating polypropylene fiber into road construction projects, countries can build safer, more resilient, and more efficient transportation infrastructure for the future.