Table of Contents

Advantages of Heat Transfer Oil: Exploring Its Importance in Industrial Processes

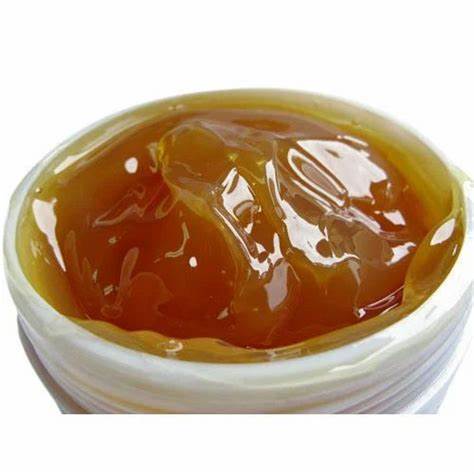

Heat transfer oil plays a crucial role in industrial processes, facilitating the efficient transfer of heat within machinery and equipment. Among the various suppliers of heat transfer oil, China stands out as home to some of the best factories producing high-quality products. Understanding the advantages of heat transfer oil and its significance in industrial operations sheds light on why choosing the right supplier is paramount.

In the realm of industrial operations, heat transfer is a fundamental process essential for various applications, including heating, cooling, and temperature control. Heat transfer oils serve as the medium through which thermal energy is transferred from one system to another. Unlike water, which can freeze or evaporate under extreme conditions, heat transfer oils offer stability across a wide temperature range, making them ideal for diverse industrial environments.

One of the primary advantages of heat transfer oil lies in its superior thermal stability. These oils can withstand high operating temperatures without degrading, ensuring consistent performance and prolonged equipment lifespan. This stability minimizes the risk of overheating and equipment failure, enhancing operational reliability in industrial settings.

Furthermore, heat transfer oils exhibit excellent thermal conductivity, enabling efficient heat transfer across machinery and equipment. This property ensures uniform temperature distribution, optimizing the performance of industrial processes while minimizing energy consumption. As a result, businesses can achieve greater efficiency and productivity, translating into cost savings and competitive advantages.

In addition to thermal stability and conductivity, heat transfer oils offer excellent chemical resistance, protecting equipment from corrosion and degradation caused by exposure to harsh operating conditions and chemical substances. This resistance enhances the durability of machinery, reducing maintenance requirements and downtime, thereby maximizing productivity and profitability.

Choosing the right supplier for heat transfer oil is crucial to ensuring product quality and reliability. China boasts some of the best factories specializing in the production of heat transfer oil, renowned for their adherence to stringent quality standards and use of advanced manufacturing processes. These factories leverage cutting-edge technology and expertise to produce high-quality heat transfer oils tailored to meet the diverse needs of industrial applications.

Moreover, China’s position as a global manufacturing hub allows for cost-effective production and distribution of heat transfer oils, making them accessible to businesses worldwide. This affordability, coupled with uncompromising quality, makes Chinese heat transfer oil factories a preferred choice for industries seeking reliable thermal solutions.

In conclusion, heat transfer oil plays a vital role in industrial processes, facilitating efficient heat transfer and temperature control within machinery and equipment. The advantages of heat transfer oil, including thermal stability, conductivity, and chemical resistance, underscore its importance in optimizing industrial operations. When selecting a supplier, China’s leading factories emerge as top contenders, offering high-quality products at competitive prices. By leveraging the expertise and resources of these factories, businesses can enhance their operational efficiency, reliability, and competitiveness in the global market.

Top 5 Factors to Consider When Choosing the Best Heat Transfer Oil Factory in China

When it comes to selecting the best heat transfer oil factory in China, there are several crucial factors to consider. China has become a hub for manufacturing various industrial products, including heat transfer oils. However, not all factories are created equal, and choosing the right one can significantly impact the efficiency and performance of your operations. Here are the top five factors to consider when making your decision.

First and foremost, it’s essential to assess the quality of the heat transfer oil produced by the factory. Quality should always be a priority to ensure optimal performance and longevity of your equipment. Look for a factory that adheres to stringent quality control measures and uses high-grade raw materials in the production process. Additionally, consider factors such as viscosity, thermal stability, and heat transfer efficiency when evaluating the quality of the oil.

Secondly, consider the factory’s production capacity and capabilities. Depending on your specific requirements, you’ll want to choose a factory that can meet your demand for heat transfer oil consistently. Evaluate factors such as production volume, Lead times, and scalability to determine whether the factory can accommodate your needs both now and in the future. A factory with advanced manufacturing facilities and efficient production processes is more likely to deliver timely and reliable results.

Next, it’s crucial to assess the factory’s reputation and track record in the industry. Look for reviews, testimonials, and references from past clients to gauge the factory’s reliability and customer satisfaction Levels. A reputable factory with a history of delivering high-quality products and excellent service is more likely to meet your expectations and provide a positive experience.

In addition to quality and capacity, consider the factory’s location and logistics capabilities. Opting for a factory located in close proximity to major transportation hubs can help streamline the shipping process and reduce lead times. Moreover, assess the factory’s logistical infrastructure, including storage facilities and distribution networks, to ensure efficient and cost-effective delivery of the heat transfer oil to your location.

| Brand | Product |

| MoGen | Lubricating oils |

Finally, consider the pricing and cost-effectiveness of the heat transfer oil offered by the factory. While it’s essential to prioritize quality and reliability, you also need to ensure that the products are competitively priced and offer good value for money. Compare quotes from multiple factories and carefully evaluate the pricing structure, including any additional fees or charges, to make an informed decision.

In conclusion, choosing the best heat transfer oil factory in China requires careful consideration of several key factors. By prioritizing quality, capacity, reputation, logistics, and pricing, you can ensure that you partner with a reliable and trustworthy factory that meets your specific needs and requirements. Investing time and effort into the selection process upfront can lead to long-term benefits and success for your business.