Table of Contents

Importance of Good Quality Coupling for Casing and Tubing in Oil Well Drilling Operations

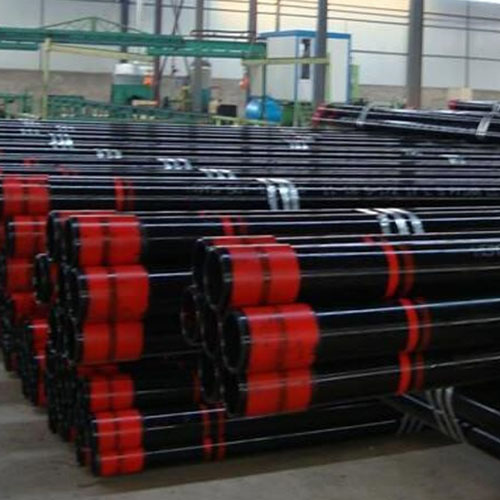

Good Quality Coupling of Casing & Tubing for Oil Well Drilling

In the realm of oil well drilling operations, the importance of good quality coupling for casing and tubing cannot be overstated. This critical component plays a pivotal role in ensuring the integrity and efficiency of the drilling process, making it essential for the successful extraction of oil and gas from the earth’s depths.

One of the primary reasons why good quality coupling is crucial for casing and tubing in oil well drilling operations is its role in maintaining the structural integrity of the well. Casing and tubing are essential for providing structural support and maintaining the wellbore’s integrity, and the coupling serves as a crucial link that connects these components. A high-quality coupling ensures a secure and reliable connection between the casing and tubing, thereby preventing potential leaks, blowouts, and other hazardous incidents that could compromise the Safety and productivity of the drilling operation.

Furthermore, the quality of the coupling directly impacts the overall performance and longevity of the well. A well-designed and robust coupling not only enhances the structural integrity of the casing and tubing but also contributes to the overall efficiency and productivity of the drilling process. By minimizing the risk of corrosion, fatigue, and other forms of mechanical failure, a good quality coupling helps to prolong the operational lifespan of the well, reducing the need for frequent maintenance and costly repairs.

Moreover, the significance of good quality coupling for casing and tubing in oil well drilling operations extends to environmental and regulatory considerations. In an industry where environmental stewardship and compliance with stringent regulations are paramount, the integrity of the wellbore and the prevention of leaks or spills are of utmost importance. A well-engineered coupling that meets industry standards and specifications can significantly reduce the likelihood of environmental contamination and mitigate the potential impact of drilling operations on surrounding ecosystems.

Another critical aspect of good quality coupling for casing and tubing in oil well drilling operations is its contribution to the overall safety of the drilling site and personnel. A secure and reliable coupling minimizes the risk of accidents and hazards associated with the handling and operation of casing and tubing, ensuring a safer working Environment for the workforce involved in the drilling process.

In conclusion, the importance of good quality coupling for casing and tubing in oil well drilling operations cannot be overstated. From maintaining structural integrity and enhancing operational efficiency to ensuring environmental compliance and promoting safety, the role of the coupling is indispensable in the successful execution of drilling operations. Therefore, investing in high-quality couplings that meet industry standards and specifications is not only a prudent business decision