Table of Contents

Avantages de l’utilisation de tuyaux en acier sans soudure au carbone ASTM A106b/A53b Sch40 dans les applications de puits de pétrole et de gaz

Comparaison des techniques de laminage à chaud et à froid pour la fabrication de tuyaux en acier sans soudure au carbone

Importance du contrôle qualité et des tests dans la production de tuyaux en acier sans soudure au carbone ASTM A106b/A53b Sch40 pour l’industrie pétrolière et gazière

En conclusion, le contrôle qualité et les tests sont essentiels dans la production de tuyaux en acier sans soudure au carbone ASTM A106b/A53b Sch40 pour l’industrie pétrolière et gazière. Ces procédures aident à identifier tout défaut ou incohérence dans le matériau, garantissant ainsi que seuls des tuyaux de la plus haute qualité sont utilisés sur le terrain. En adhérant à des normes strictes de contrôle de qualité et de tests, les fabricants peuvent fournir des tuyaux fiables et durables qui répondent aux exigences exigeantes de l’industrie pétrolière et gazière.

Importance of Quality Control and Testing in Producing ASTM A106b/A53b Sch40 Carbon Seamless Steel Pipe for Oil and Gas Industry

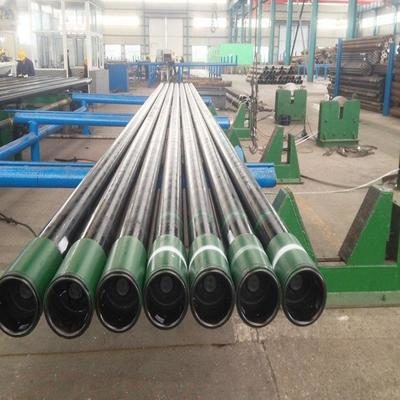

In the oil and gas industry, the demand for high-quality materials is paramount. One such material that is widely used in this industry is ASTM A106b/A53b Sch40 carbon seamless steel pipe. These pipes are essential for Transporting oil and gas from the well to the processing facilities. The quality of these pipes is crucial as any defects or weaknesses can Lead to catastrophic failures, resulting in costly repairs and potential harm to the Environment and workers.

To ensure the quality of ASTM A106b/A53b Sch40 carbon seamless Steel Pipes, rigorous quality control and testing procedures are implemented throughout the manufacturing process. These procedures are essential in identifying any defects or inconsistencies in the material, ensuring that only the highest quality pipes are used in the oil and gas industry.

One of the key aspects of quality control in producing ASTM A106b/A53b Sch40 carbon seamless steel pipes is the inspection of raw materials. The quality of the raw materials used in the manufacturing process directly impacts the final product. Therefore, it is crucial to carefully inspect and test the raw materials to ensure they meet the required specifications and standards. This includes checking the chemical composition, mechanical properties, and overall quality of the materials.

Once the raw materials have been inspected and approved, the manufacturing process begins. During the production of ASTM A106b/A53b Sch40 carbon seamless steel pipes, various tests and inspections are conducted at different stages to ensure the quality of the pipes. These tests may include visual inspections, dimensional checks, ultrasonic testing, and hydrostatic testing, among others. These tests help identify any defects or inconsistencies in the pipes, allowing for corrective actions to be taken before the pipes are used in the field.

In addition to the manufacturing process, quality control and testing also play a crucial role in the final inspection of ASTM A106b/A53b Sch40 carbon seamless steel pipes. Before the pipes are shipped to the customers, a final inspection is conducted to ensure that the pipes meet all the required specifications and standards. This final inspection may include visual inspections, non-destructive testing, and dimensional checks, among others. Only after passing these rigorous inspections are the pipes deemed ready for use in the oil and gas industry.

The importance of quality control and testing in producing ASTM A106b/A53b Sch40 carbon seamless steel pipes cannot be overstated. These pipes are essential for the safe and efficient transportation of oil and gas, and any defects or weaknesses in the material can have serious consequences. By implementing strict quality control and testing procedures throughout the manufacturing process, manufacturers can ensure that only the highest quality pipes are used in the oil and gas industry.

https://www.youtube.com/watch?v=q2IbtWO5RVwIn conclusion, quality control and testing are essential in producing ASTM A106b/A53b Sch40 carbon seamless steel pipes for the oil and gas industry. These procedures help identify any defects or inconsistencies in the material, ensuring that only the highest quality pipes are used in the field. By adhering to strict quality control and testing standards, manufacturers can provide reliable and durable pipes that meet the demanding requirements of the oil and gas industry.